A Stress Relief Structure for Improving the Reliability of Hermetic Welding of Multi-core Connectors

A technology for stress relief and connectors, which is applied to parts, connections, and electrical components of connecting devices, can solve problems such as complex features, cracking and air leakage of connectors, and small sintered surfaces, so as to reduce packaging weight, change rigidity, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

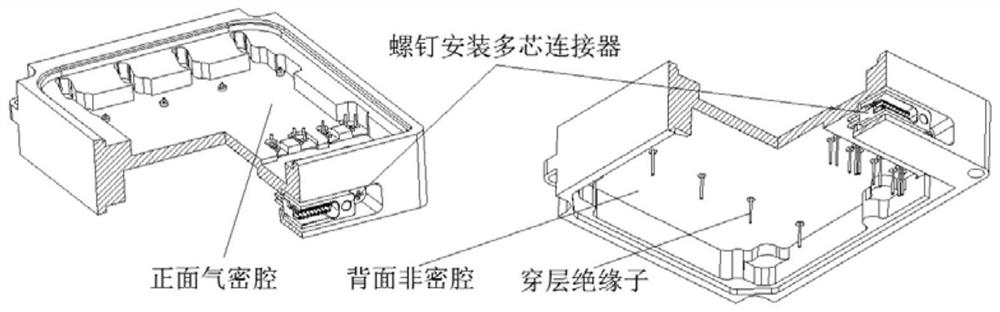

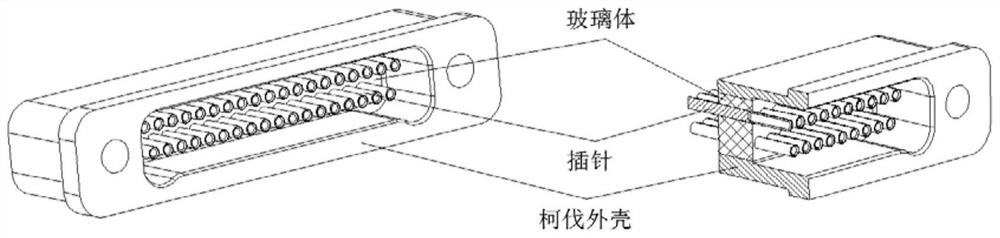

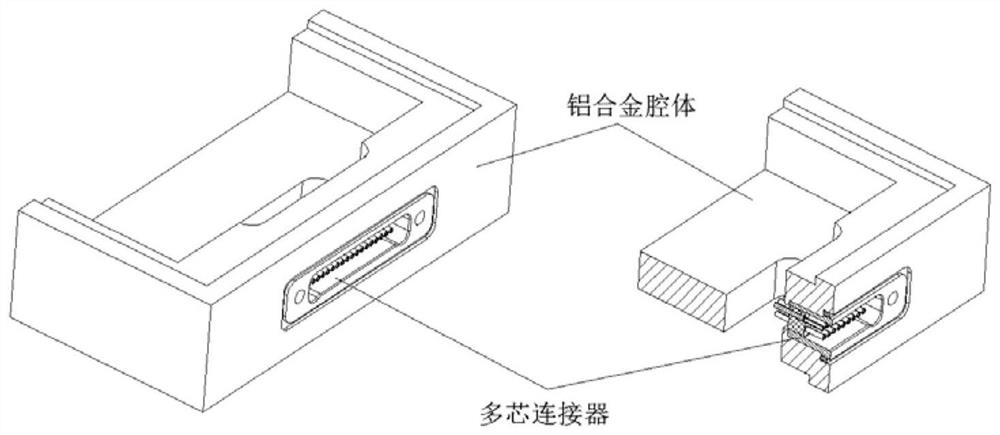

[0029] The stress relief structure for improving the reliability of airtight welding of multi-core connectors in the present invention includes an elastic transition zone, and the elastic transition zone is arranged between the multi-core connector and the main structure of the cavity. When airtight welding is realized, the The elastic transition zone can effectively reduce the stress concentration of joints caused by temperature changes. The elastic transition zone can be a component provided separately, or it can be provided on the cavity body and integrally formed with the cavity body. The size of the stress relief structure can be flexibly adjusted according to the thickness of the cavity and the actual processing capacity.

[0030] Preferably, a concave portion is provided on one side surface of the elastic transition zone, and the one side surface refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com