A novel environmental barrier coating and structure for sic ceramic matrix composites

A composite material and environmental barrier technology, applied in the field of coating, can solve the problem of low comprehensive protection performance, and achieve the effect of excellent comprehensive performance, excellent corrosion resistance and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

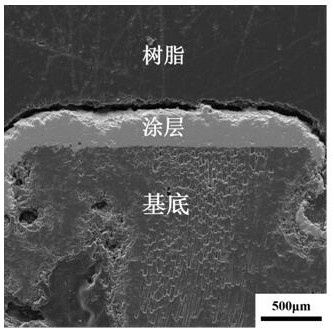

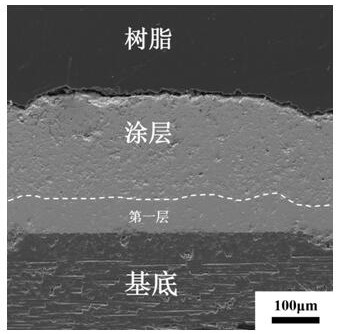

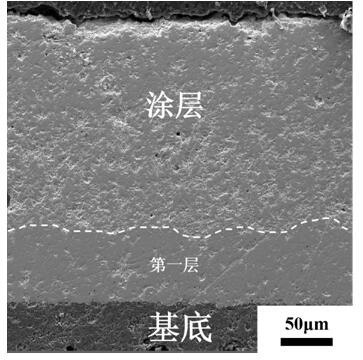

Image

Examples

preparation example Construction

[0049] The present invention also proposes a method for preparing a novel environmental barrier coating for SiC ceramic matrix composites as described above, comprising the following steps:

[0050] S1: Pre-treat the SiC ceramic composite substrate by sandblasting, ultrasonic cleaning and sufficient drying;

[0051] S2: Using the atmospheric plasma spraying process to prepare Ta-rich on the surface of the substrate obtained in S1 2 o 5 Hf 6 Ta 2 o 17 -Ta 2 o 5 Composite ceramic layer;

[0052] S3: Using the atmospheric plasma spraying process to prepare Hf-rich on the surface of the coating obtained in S2 6 Ta 2 o 17 Hf 6 Ta2 o 17 -Ta 2 o 5 Composite ceramic layer;

[0053] S4: Using the atmospheric plasma spraying process to prepare Hf on the surface of the coating obtained in S3 6 Ta 2 o 17 A single-phase ceramic layer is used to obtain a new type of environmental barrier coating.

[0054] The preparation method of the new environmental barrier coating for ...

Embodiment 1

[0056] This embodiment provides a novel environmental barrier coating for SiC ceramic matrix composites as a layered structure, including an inner layer, a middle layer and an outer layer; the coefficient of thermal expansion of the inner layer is 5×10 -6 / K, with a thickness of 80 μm.

[0057] The thermal expansion coefficient of the middle layer is 6×10 -6 / K, the thickness is 100 μm.

[0058] The thermal expansion coefficient of the outer layer is 8×10 -6 / K, with a thickness of 110 μm.

[0059] The preparation process of the novel environmental barrier coating is as follows:

[0060] S1: Use corundum sand for C f / SiC composite material substrate is pre-treated by sandblasting, and fully dried after ultrasonic cleaning;

[0061] S2: Using the atmospheric plasma spraying process, the C obtained in S1 f Ta-rich preparation on the substrate surface of / SiC composite material 2 o 5 Hf 6 Ta 2 o 17 -Ta 2 o 5 Inner layer, Hf in the powder used for spraying 6 Ta 2 o...

Embodiment 2

[0066] This embodiment provides a novel environmental barrier coating for SiC ceramic matrix composites as a layered structure, including an inner layer, a middle layer and an outer layer; the coefficient of thermal expansion of the inner layer is 6×10 -6 / K, the thickness is 90 μm.

[0067] The thermal expansion coefficient of the middle layer is 7×10 -6 / K, with a thickness of 120 μm.

[0068] The thermal expansion coefficient of the outer layer is 9×10 -6 / K, with a thickness of 120 μm.

[0069] The preparation process of the novel environmental barrier coating is as follows:

[0070] S1: Use corundum sand for C f / SiC composite material substrate is pre-treated by sandblasting, and fully dried after ultrasonic cleaning;

[0071] S2: Using the atmospheric plasma spraying process, the C obtained in S1 f Ta-rich preparation on the substrate surface of / SiC composite material 2 o 5 Hf 6 Ta 2 o 17 -Ta 2 o 5 Innermost layer, Hf of the powder used for spraying 6 Ta ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com