Continuous ultra high-temperature sterilization technology for granule-containing beverage

An ultra-high temperature sterilization and continuous technology, which is applied in the direction of mixers, dissolvers, and mixers with rotating stirring devices, can solve the problems of particle precipitation, heating and sterilization, particle damage, etc., and achieve high heat exchange efficiency and taste And the effect of stable quality and guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

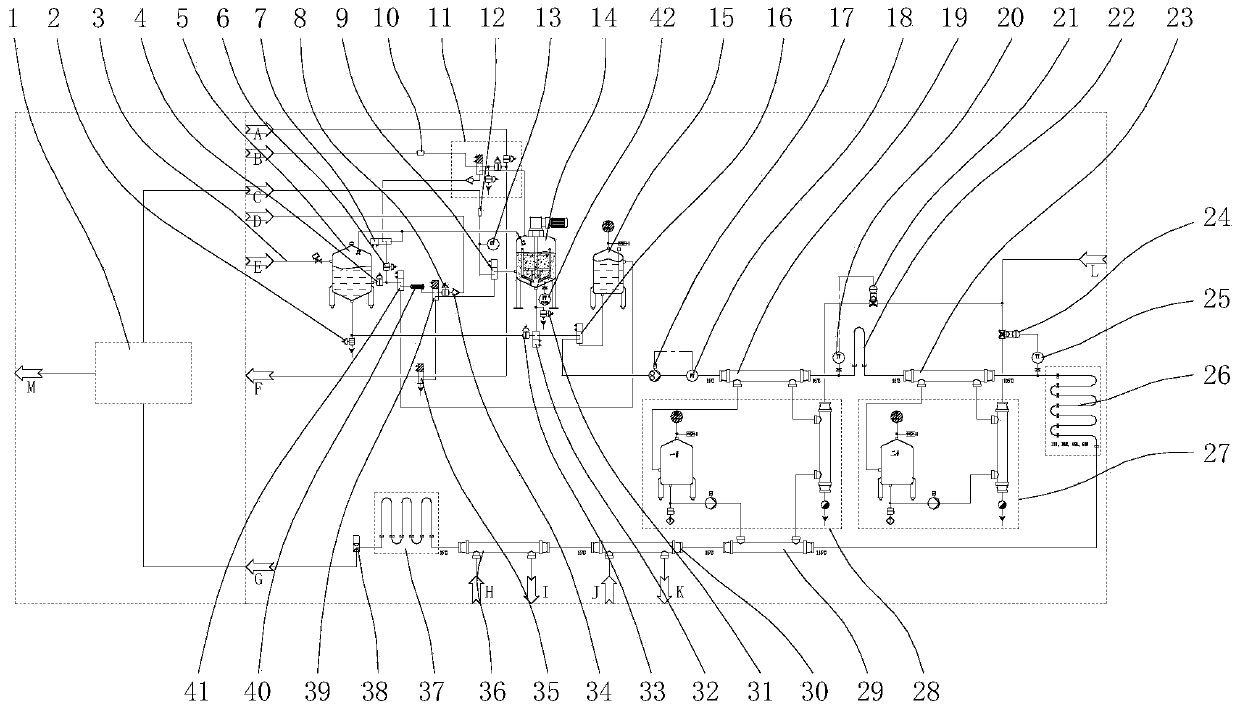

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The process of the present invention is used to process materials with a concentration of ≤60%, that is, materials with a pulp particle content of not more than 60g in 100g of materials, and the materials are made by mixing pulp particles with a specification of ≤5×5×5mm and feed liquid in proportion.

[0024] The processing technology of the present invention adopts a step-by-step heating mode of one set of hot water heating system 28 and two sets of hot water heating systems 27, and sets different pre-heating temperatures according to product characteristics, and enters the pre-heating heat exchanger 19 for pre-heating. Heating, such as 95°C, enters the pre-heating holder 22 at this temperature, and holds the temperature for a specific time: such as 10s, 20s, 30s, etc. The length of the holding time is determined according to the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com