Nail bin assembly of endoscope cutting stapler

A stapler and staple cartridge technology, which is applied in the field of staple cartridge components of endoscopic cutting staplers, can solve the problems of reduced positioning accuracy, low rigidity of staple cartridge racks, increased processing costs, and the like, and achieves the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

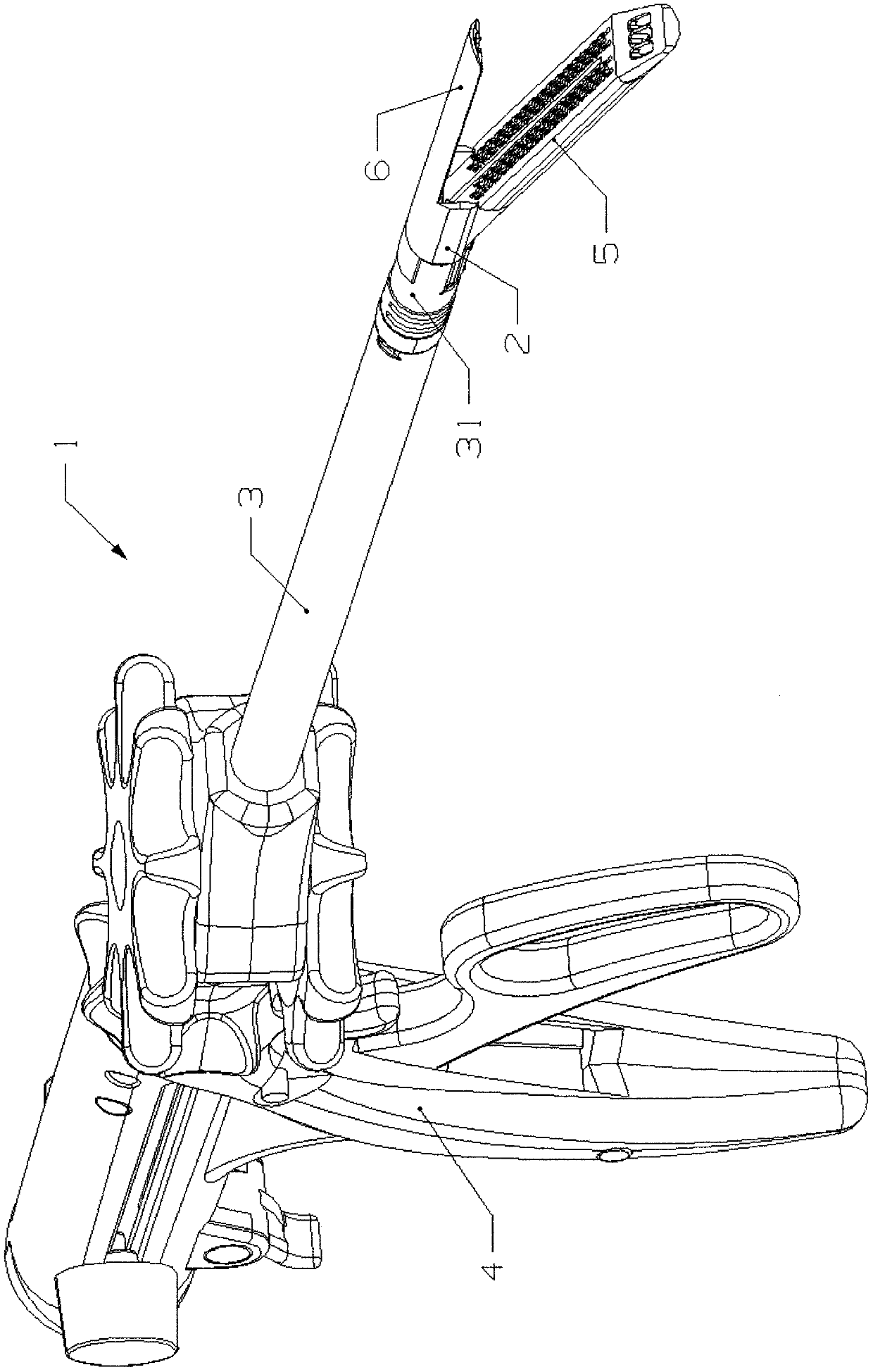

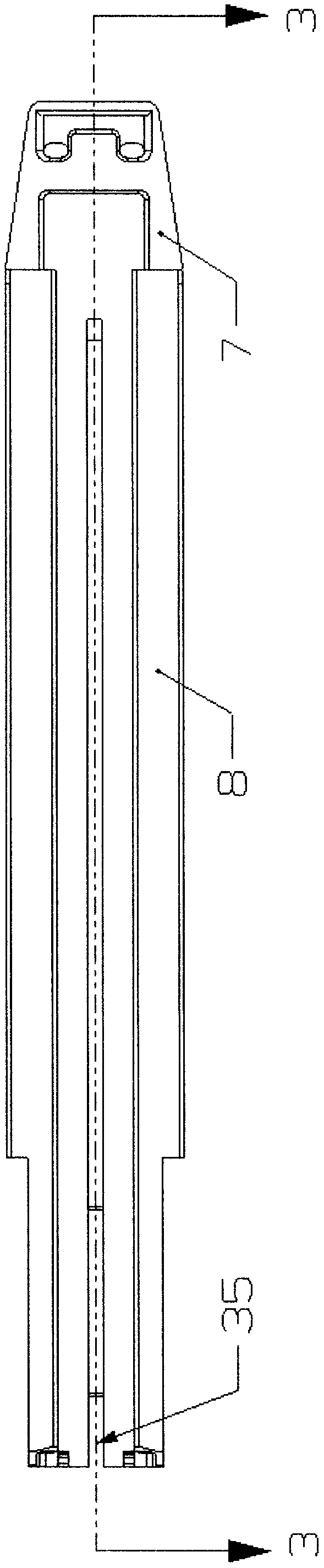

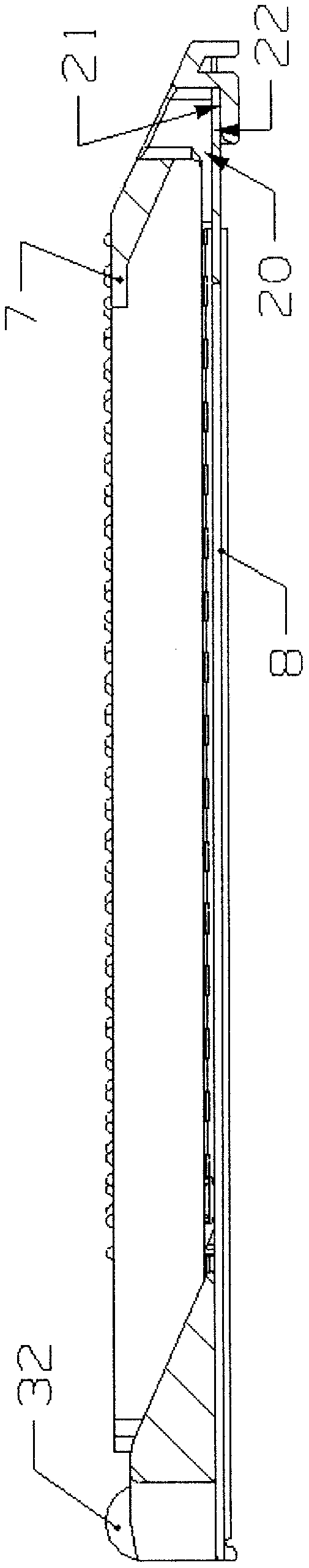

[0034] The best embodiment of the nail cartridge assembly of the laparoscopic cutting stapler of the present invention will be described below by way of example with reference to the accompanying drawings. The scope of the invention will be indicated in the claims. It should be recognized that some or all of the drawings are illustrative diagrams illustrating preferred embodiments of the invention and do not depict the true dimensions of the parts shown. The practical manner in which these and other objects and advantages of the invention are achieved will become more clearly understood by reference to the detailed description of the preferred embodiment.

[0035] In the drawings and the following description, the term "posterior" refers to a position close to the operator of the endoscopic cutting stapler, and the term "anterior" refers to a position away from the endoscopic cutting stapler operator. The term "left" refers to the left side of the laparoscopic stapler operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com