A kind of sludge recycling harmless treatment device, process and application

A technology of harmless treatment and sewage treatment system, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, sedimentation adjustment device, etc., and can solve the problem of poor surrounding environment, uneven mixing, sludge Settlement effect is poor and other problems, to achieve the effect of enhancing the separation effect of mud and water, avoiding disturbance, and reducing time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

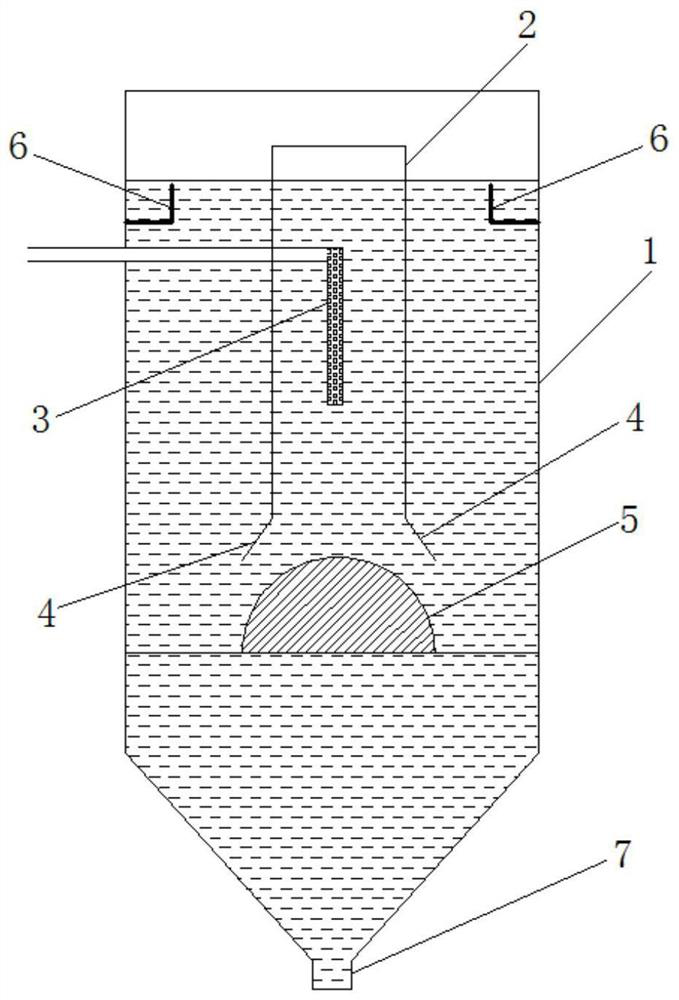

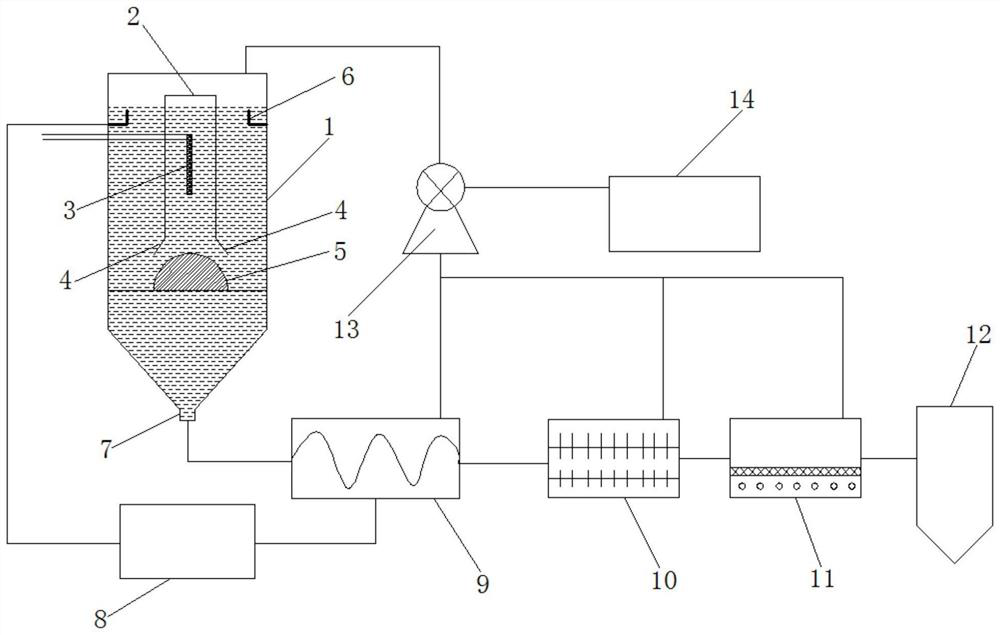

[0055] refer to figure 1 , a sludge settling device, comprising: a shell 1, a cylinder body 2, a water inlet pipe 3, a baffle plate 4, a guide plate 5, a water outlet groove 6 and a mud outlet 7, wherein: the shell 1 has an empty The structure of the cavity, the cylinder body 2 is arranged inside the casing, one end of the cylinder body is open, the other end is closed, and the open end is set downward, the water inlet pipe 3 is arranged in the cylinder body 2 and is located at the upper part of the cylinder body, Water inlet holes are distributed on the wall of the water inlet pipe, and the port of the water inlet pipe at one end of the cylinder body 2 is closed; the baffle 5 is a horn-shaped structure, which is connected to the open end of the cylinder body 2 at At the same time, the larger end of the opening of the trumpet-shaped structure is arranged downward; the deflector 6 is a spherical cap-shaped structure, which is arranged below the baffle 5; In order to facilitate...

Embodiment 2

[0057] A sludge settling device, the same as Embodiment 1, the difference is: the upper part of the casing 1 is a cylinder, the lower part is a cone, the mud outlet 7 is located at the tip of the cone, and the height of the cylinder is is 4000mm, the height of the cone is 4000mm, the diameter of the cylinder 2 is 500mm, and the height is 1500mm; the diameter of the spherical cap is 500mm, and the ratio of the center height to the diameter of the spherical cap is 0.05.

Embodiment 3

[0059] A sludge settling device, the same as the second embodiment, the difference is: the height of the cylinder is 7000mm, the height of the cone is 7000mm; the diameter of the cylinder 2 is 600mm, the height is 2500mm; the diameter of the spherical cap is 600mm, the ratio of the center height to the diameter of the spherical cap is 0.15; the angle between the inclined plane of the baffle 4 and the horizontal plane is 50°; the diameter of the spherical cap is the same as the diameter of the baffle; The vertical distance between the bottom surface and the bottom surface of the baffle is 0.8m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com