Sampling evaporator comprising automatic replacement device and used for low-pressure liquefied gas inspection

A sampling evaporator and liquefied gas technology, applied in the field of sample preparation equipment for low-pressure liquefied gas and mixed gas detection, low-pressure liquefied gas and mixed gas testing sampling evaporator field, can solve the problem of gasification of C5 components, replacement Problems such as inconvenient cleaning and replacement of samples, increased fire hazards, etc., have achieved the effect of facilitating sampling inspection of liquefied gas, improving laboratory environment and safety, and reducing test preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

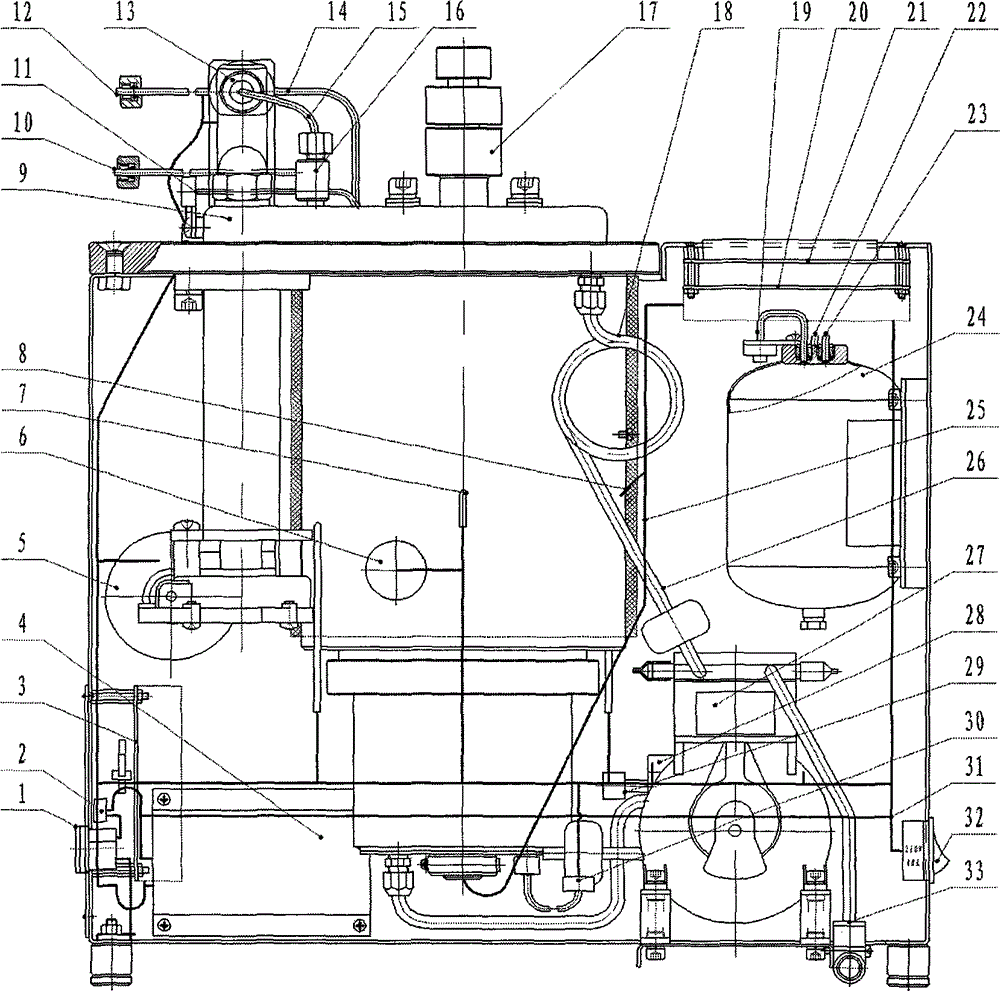

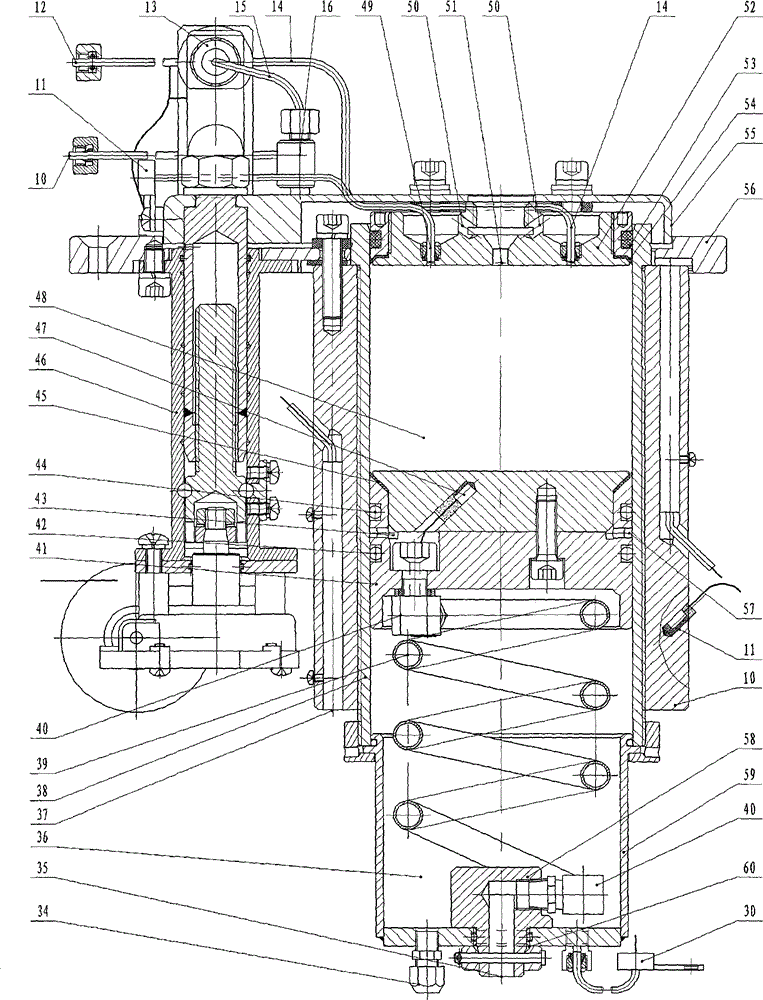

[0026] Component reference designation 1. Power socket 220VAC 10A

[0027] 2. Self-recovery fuse 240VAC 2A 33. Replacement exhaust pipe

[0028] 3. Drive plate 34. Piston driving force pumping gas connection

[0029] 4. DC power supply DC19V 4.74A 35. Atmospheric balance device opening to the atmosphere

[0030]5. Lifting motor 36. Piston lower chamber

[0031] 6. Temperature control switch KSD301 105℃ 37. Electric heating tube

[0032] 7. Heat conduction constant temperature aluminum sleeve 38. Cylinder block assembly

[0033] 8. Heat conduction constant temperature aluminum sleeve temperature sensor 39. Telescopic air pressure hose

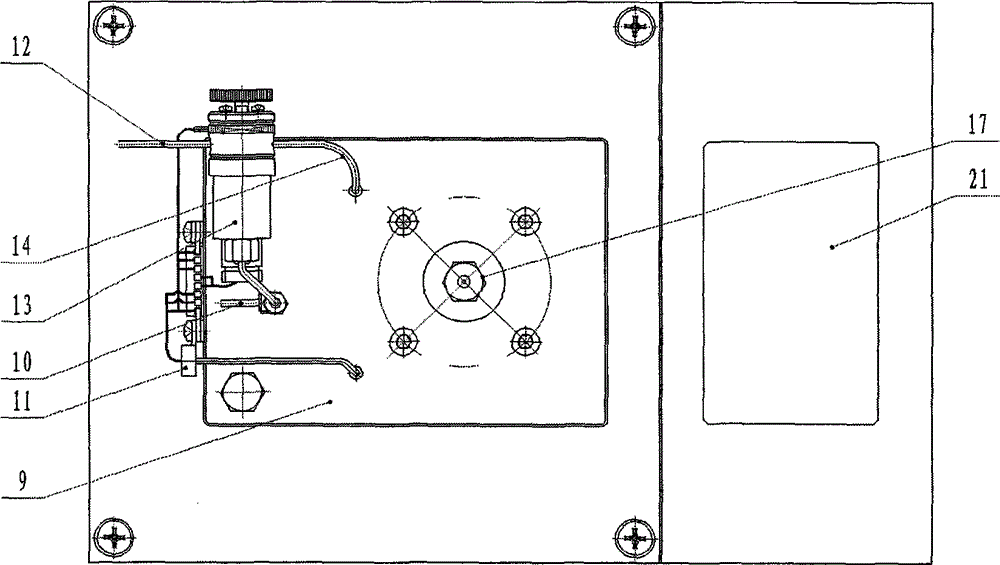

[0034] 9. Gas phase egg 40. Telescopic air pressure hose compression elbow

[0035] 10. Carrier gas input pipe for replacement 41. Piston assembly

[0036] 11. Piston upper cavity digital pressure sensor 42. Piston lower sealing ring

[0037] 12. Gas-phase medium heating pipe 43. Atmospheric balance pipe piston cavity air guide channel

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com