Intelligent sampling evaporator for low-pressure liquefied gas inspection

A technology for injecting evaporators and liquefied gases, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of easy fire and poisoning accidents, long time-consuming gasification process, reproducibility errors, etc., and achieve convenient liquefied gas The effect of sampling inspection work, improvement of laboratory environment and safety, assurance of accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

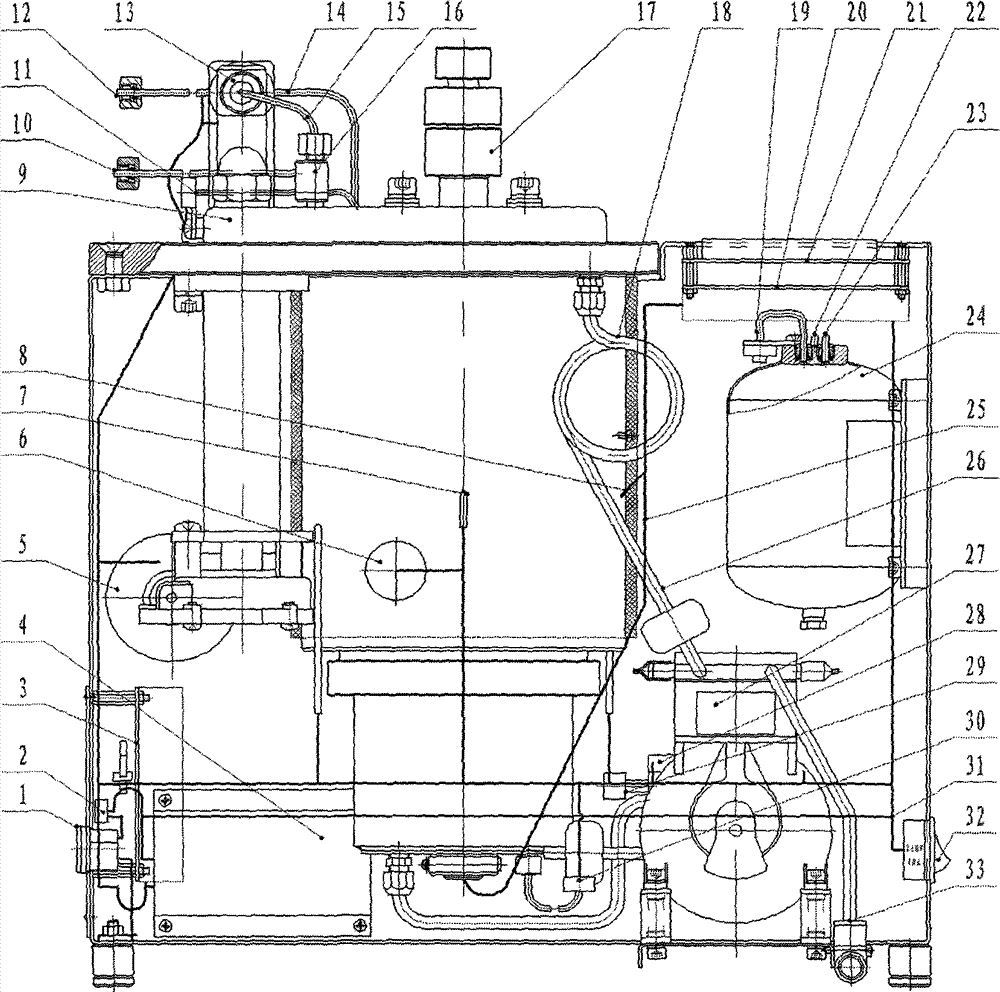

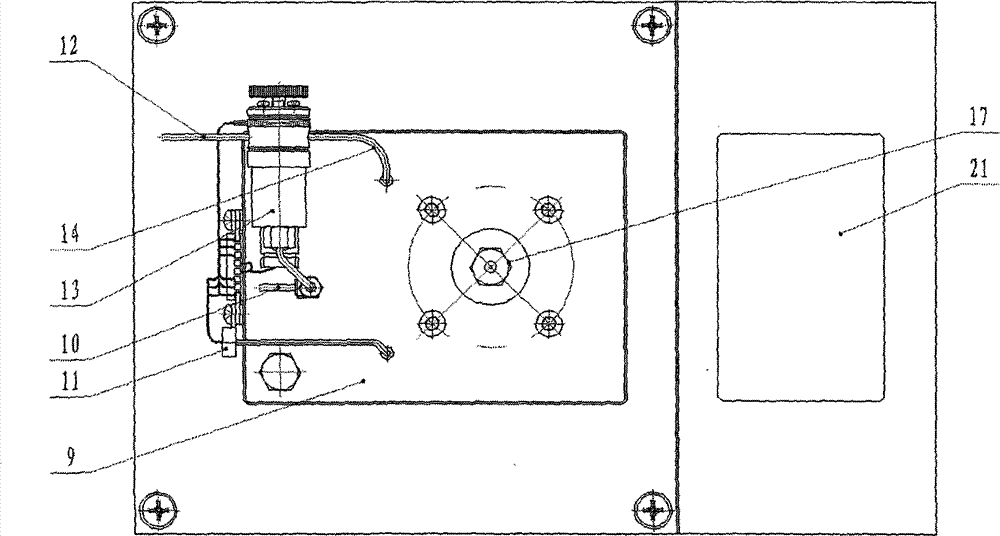

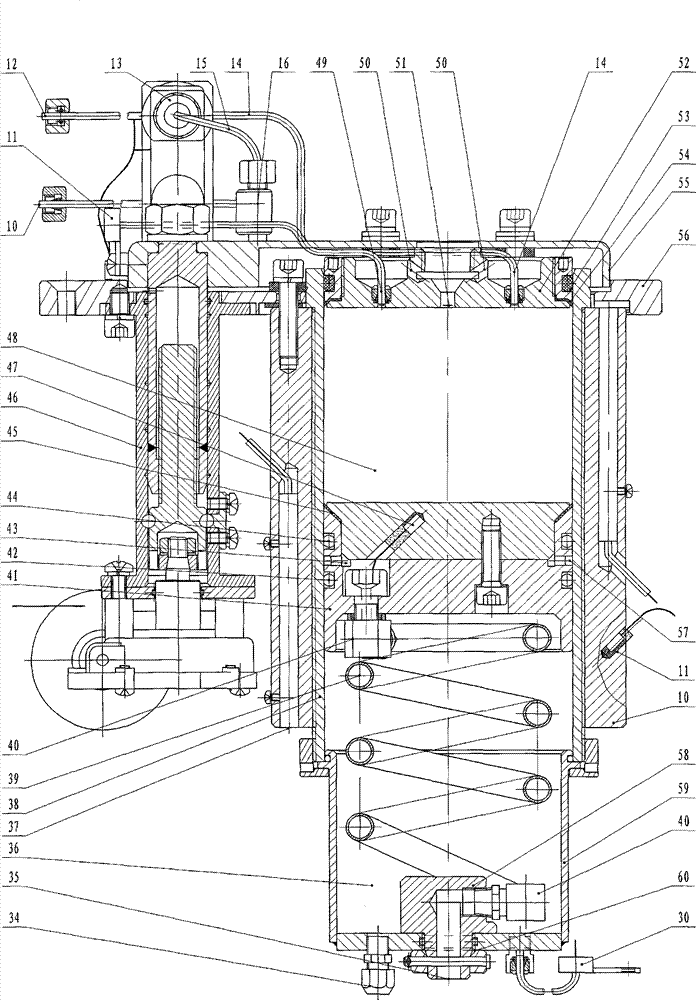

[0048] Component reference designation 6. Temperature control switch KSD301105℃

[0049] 1. Power socket 220VAC10A 7. Heat conduction constant temperature aluminum sleeve

[0050] 2. Self-recovery fuse 240VAC2A 8. Heat conduction constant temperature aluminum sleeve temperature sensor

[0051] 3. Driver board 9. Gas phase egg

[0052] 4. DC power supply DC19V4.74A 10. Carrier gas input tube for replacement

[0053] 5. Lifting motor 11. Digital pressure sensor in the upper cavity of the piston

[0054] 12. Gas-phase medium heating pipe 42. Piston lower sealing ring

[0055] 13. Air supply adjustment and replacement combined valve 43. Air guide channel in the inner cavity of the piston of the atmospheric balance pipe

[0056] 14. Air supply adjustment and replacement combined valve is connected with piston upper chamber 44. Piston upper sealing ring

[0057] Through pipe 45. Piston PTEE F4 prevents adsorption sealing ring

[0058] 15. Air supply adjustment and replacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com