A dual-capacity gas differential pressure injection-suction balanced mixed-flow quantitative sampling device

A sampling device and double-capacity technology, applied in the direction of analysis materials, instruments, etc., can solve the problems that affect the accuracy and repeatability of analysis data, require high proficiency of inspectors, and low efficiency of analysis and sampling, and achieve convenient sampling of liquefied gas The effect of inspection work, ensuring accuracy and repeatability, and less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

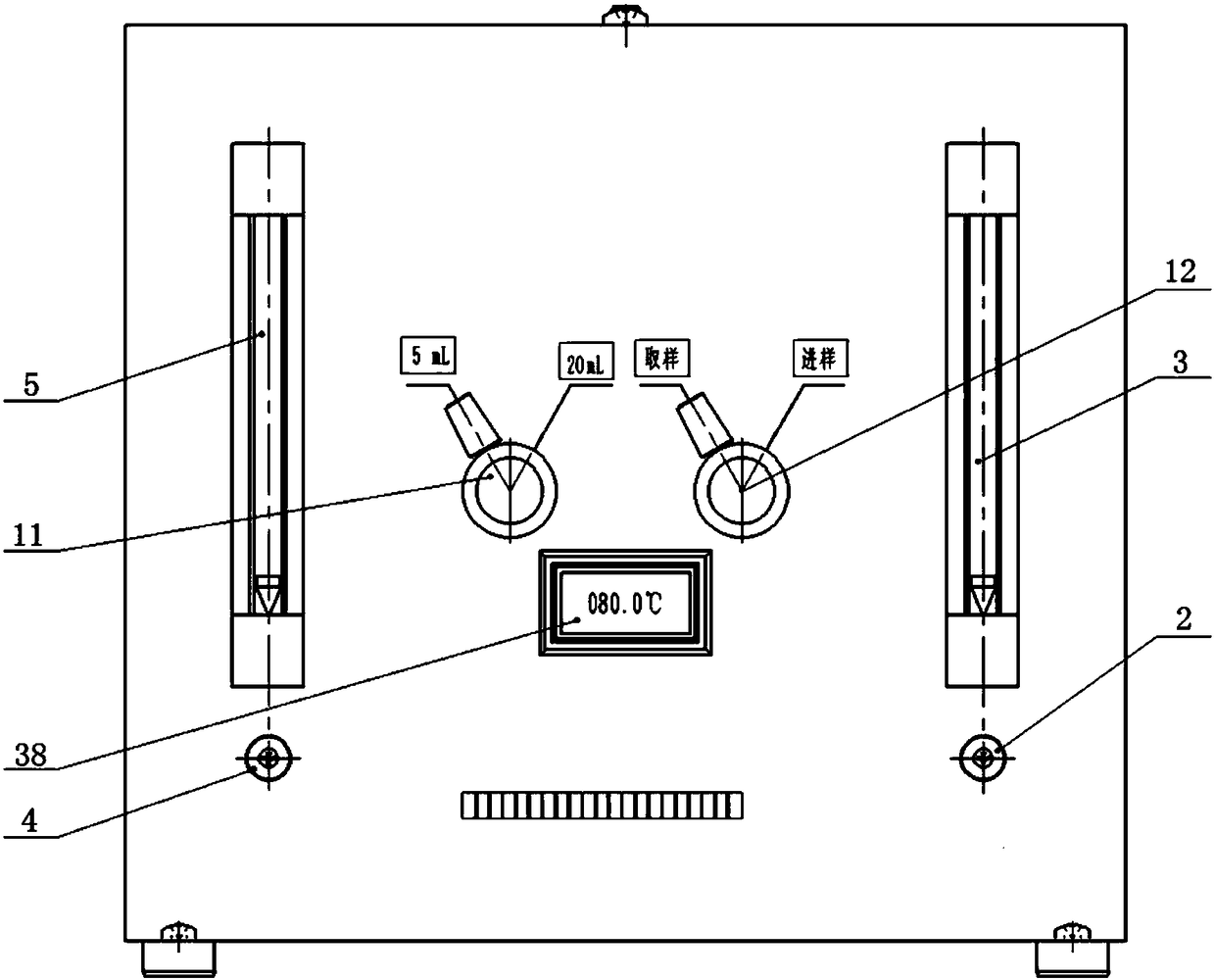

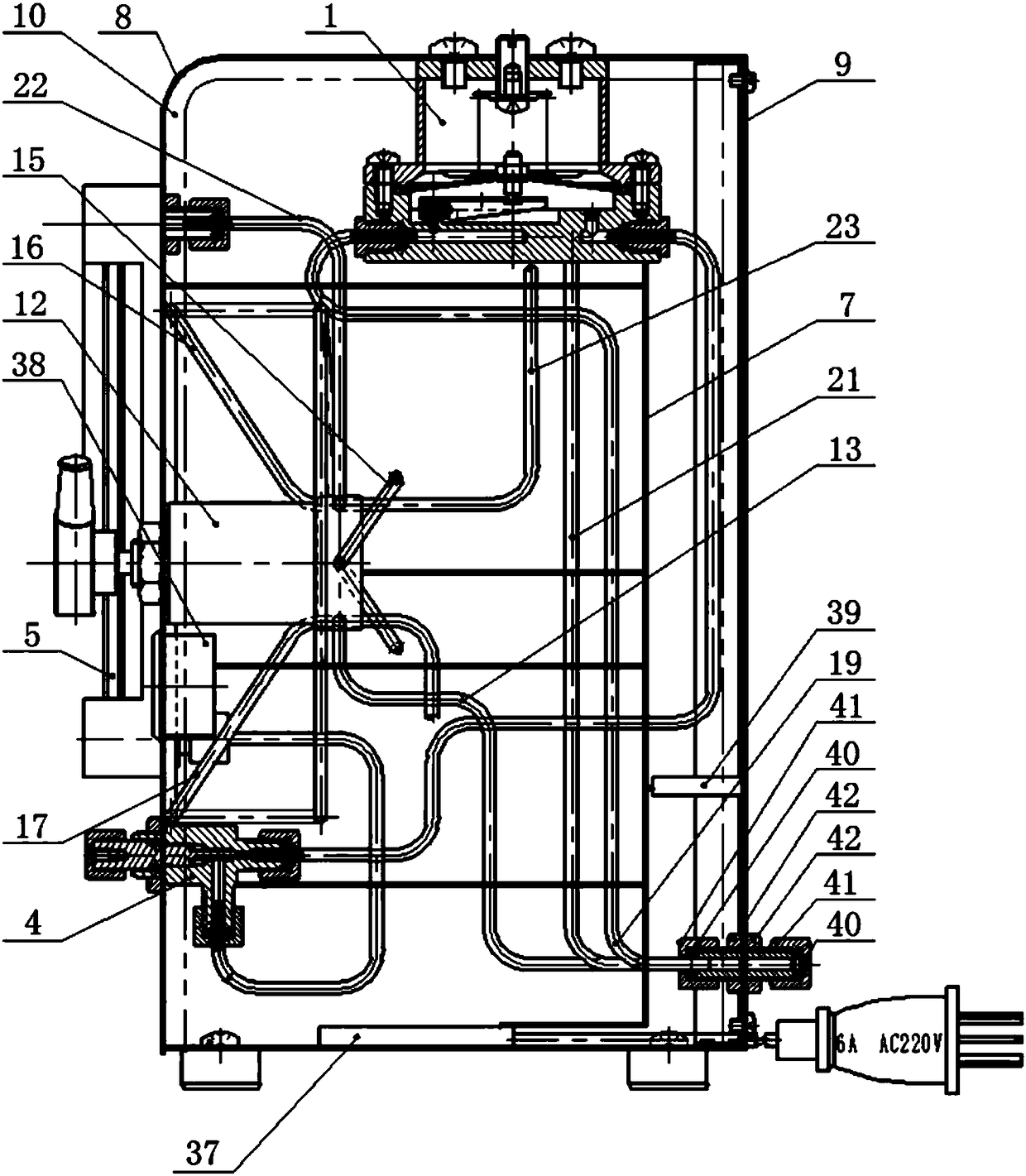

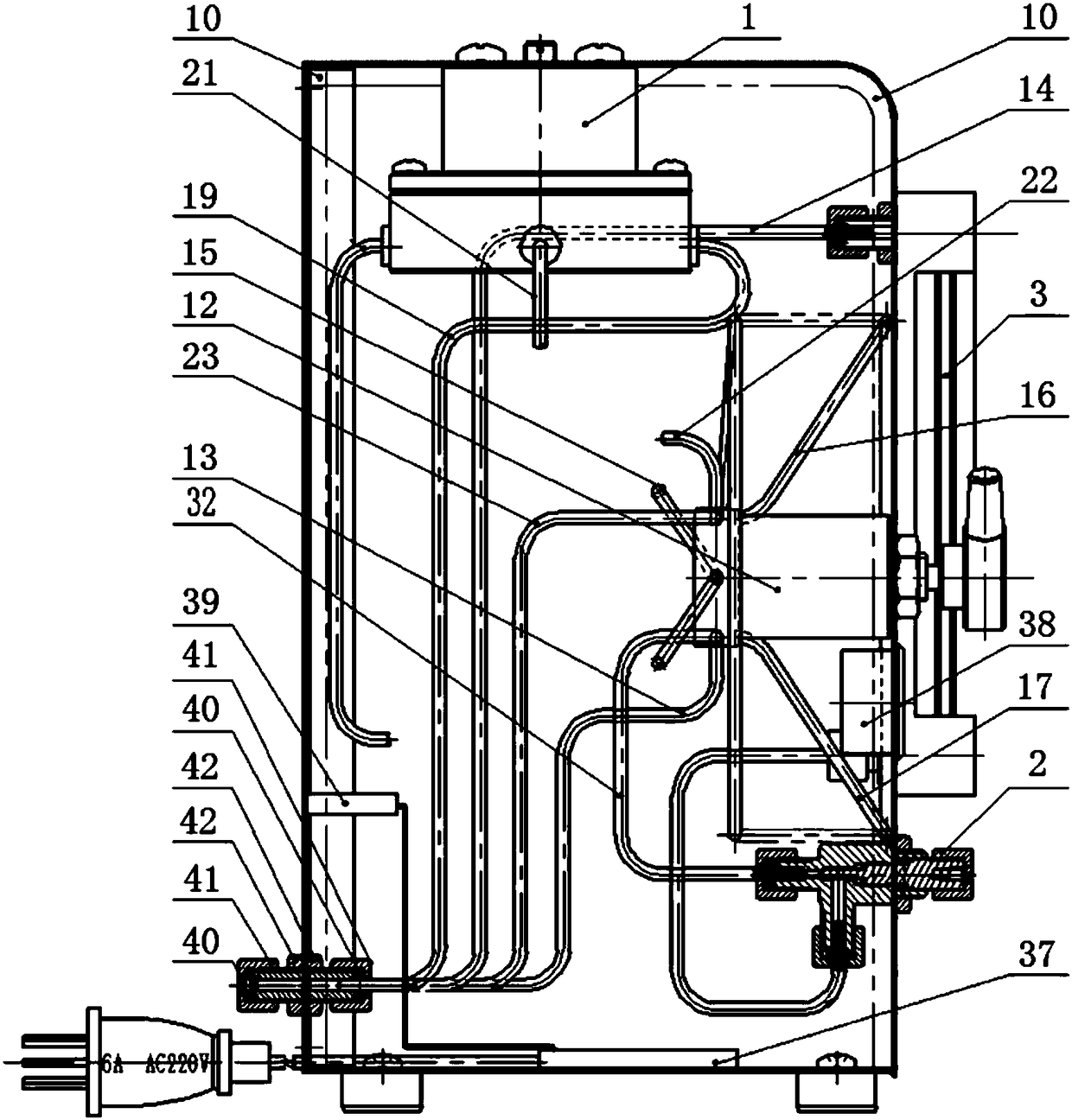

[0034] Such as Figure 1 to Figure 9As shown together, the present invention provides a dual-capacity gas differential pressure injection-suction balanced mixed-flow quantitative sampling device, which includes four quantitative tubes and two six-way valves combined to form a standard configuration of 5mL and 20mL each group of dual-capacity gas Quantitative tube, providing carrier gas decompression distribution valve 1, sample flow regulating valve 2, sample flow meter 3, carrier gas flow regulating valve 4, carrier gas flow meter 5, carrier gas input to the inspection instrument The total flow r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com