Repeated positioning precision measuring method for industrial robot

A repeatable positioning accuracy, industrial robot technology, used in measuring devices, instruments, optical devices, etc., can solve the problems of the sensor itself being not fixed, the reliability is difficult to be guaranteed, and the orthogonal method is difficult to achieve, and it is easy to save records. , The measurement method is simple and effective, and the effect of improving the repeated positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

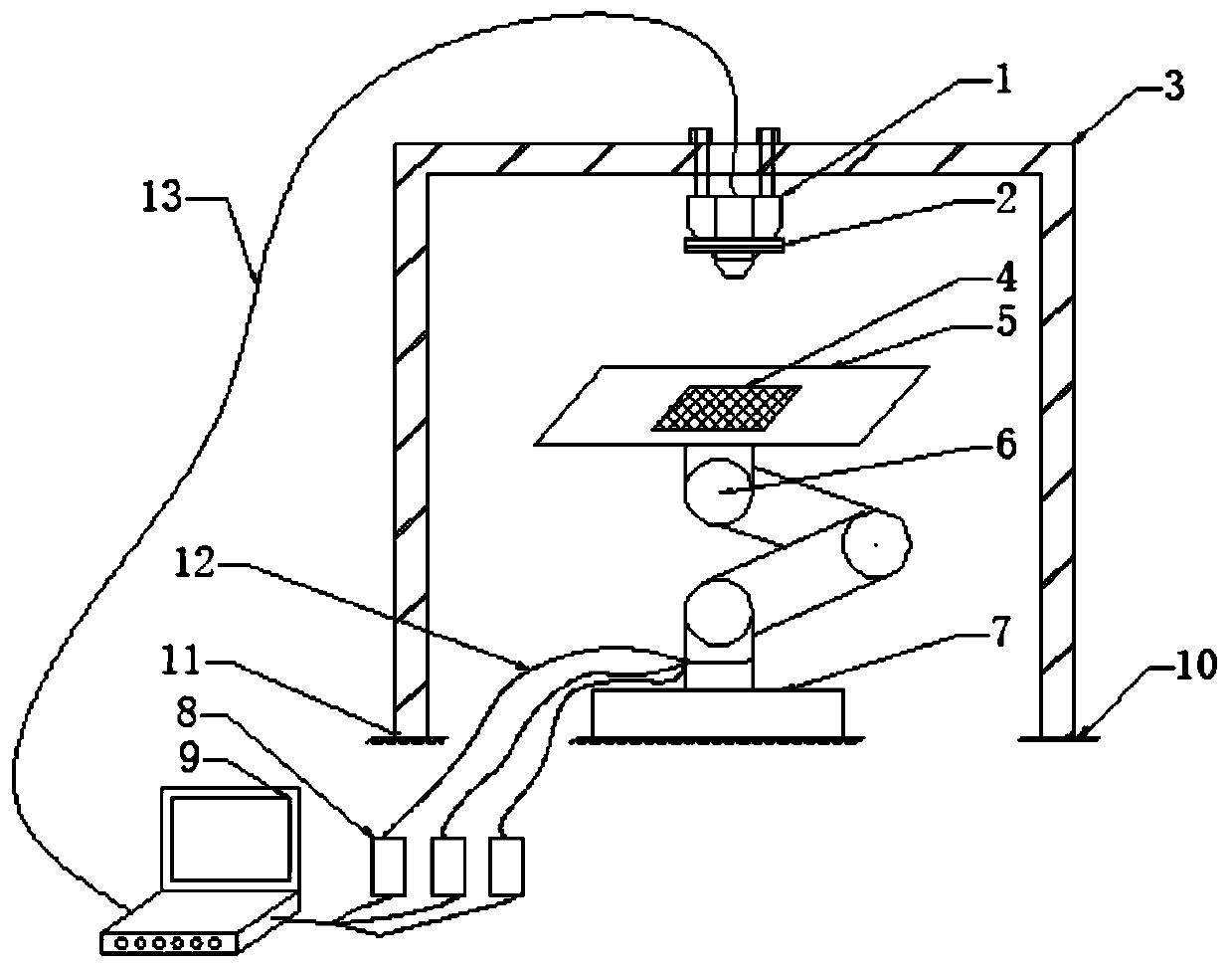

[0022] As shown in all the figures, the present invention discloses a method for measuring the repeated positioning accuracy of an industrial robot. By means of a measuring device, the measuring device includes a support base (10), a support frame (3) arranged on the support base (10), A camera (1) arranged on the support frame (3) and used as a telecentric imaging optical device of the image sensor, a mechanical arm (7) arranged under the beam of the support frame (3), and a rotating The joint (6), the image measurement platform (5) arranged on the rotating joint (6), the calibration grid (4) arranged on the image measurement platform (5) and used to detect the camera (1) and used as a registration plate , a converter (8), a computer control system (9) as an image processing system, a first connection (12) arranged between the mechanical arm (7) and the converter (8), and a computer control system (9) ) and the second connection (13) between the converter (8);

[0023] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com