True triaxial direct shear test box and method for simulating force-heat-liquid coupling environment

A true triaxial and test box technology, applied in the direction of testing material strength by applying stable shear force, preparation of test samples, sampling, etc., can solve the problem of not considering high temperature, high hydraulic pressure, inability to apply three-dimensional stress, The sealing performance of the device cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention proposes a true triaxial direct shear test box and method for simulating a force-heat-liquid coupling environment. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention is described in detail below with reference to specific embodiments. illustrate.

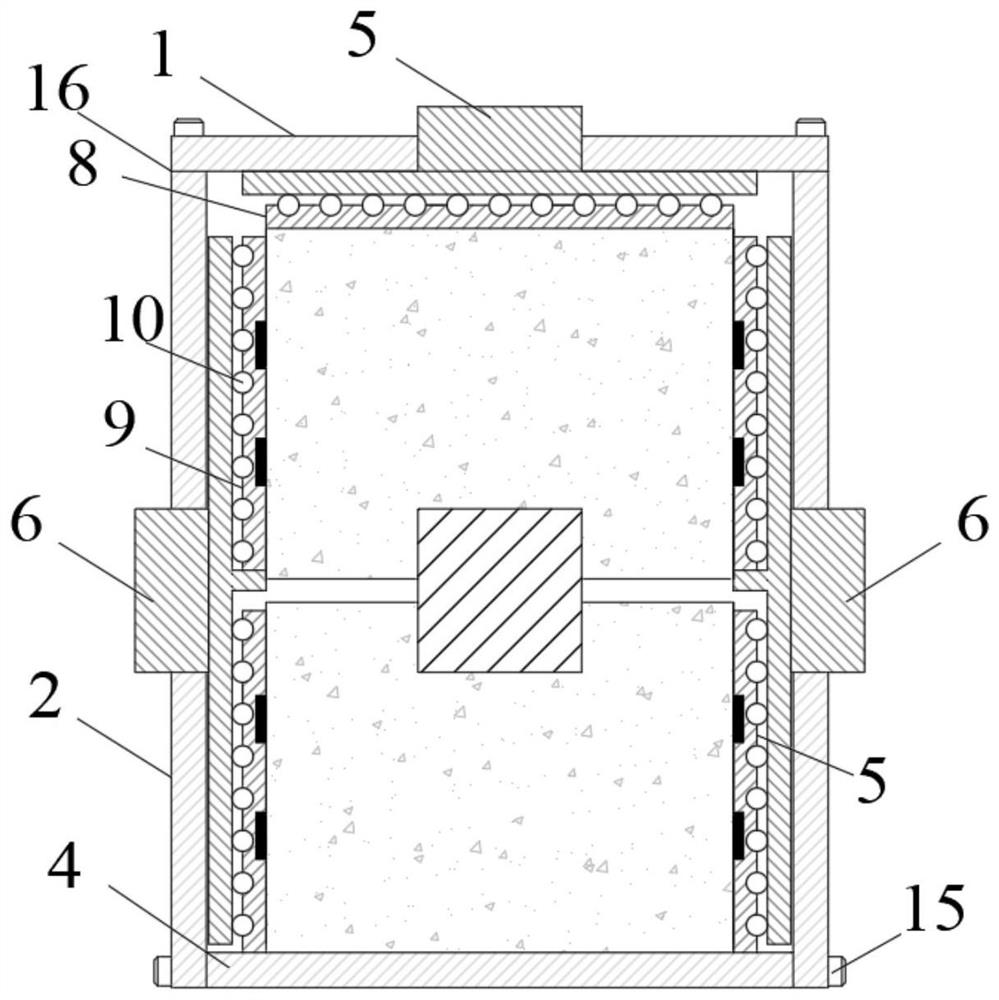

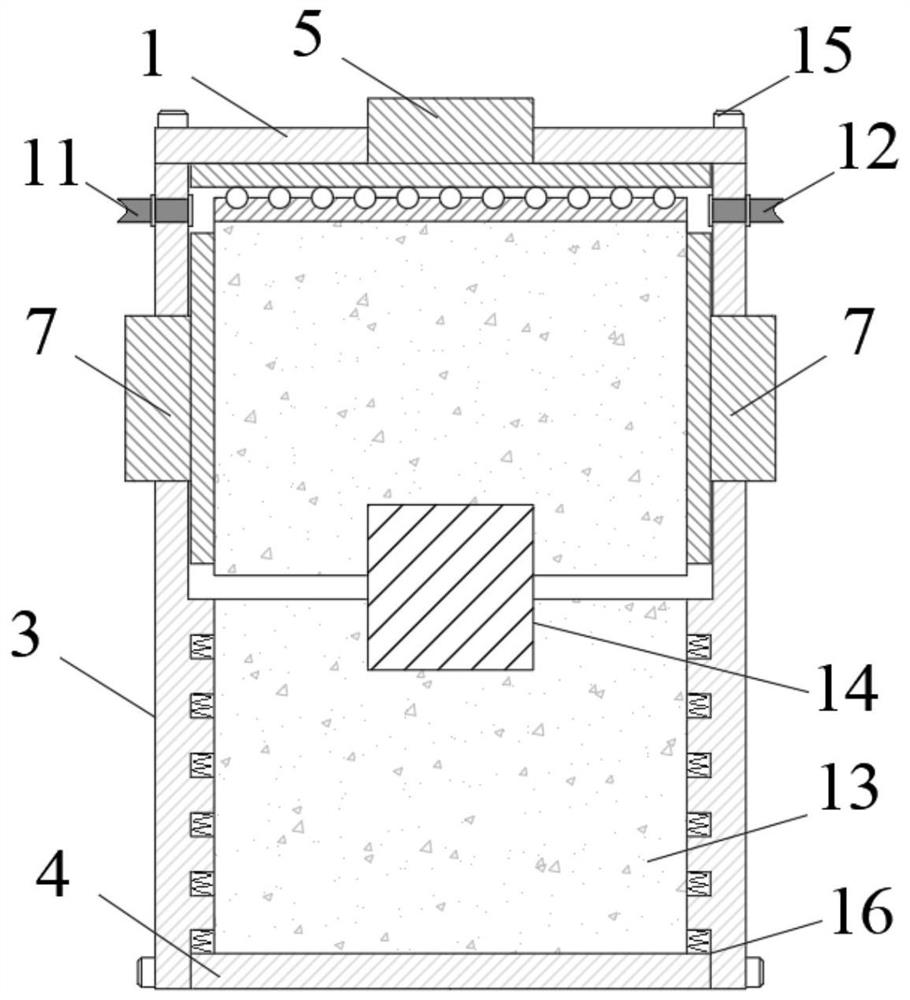

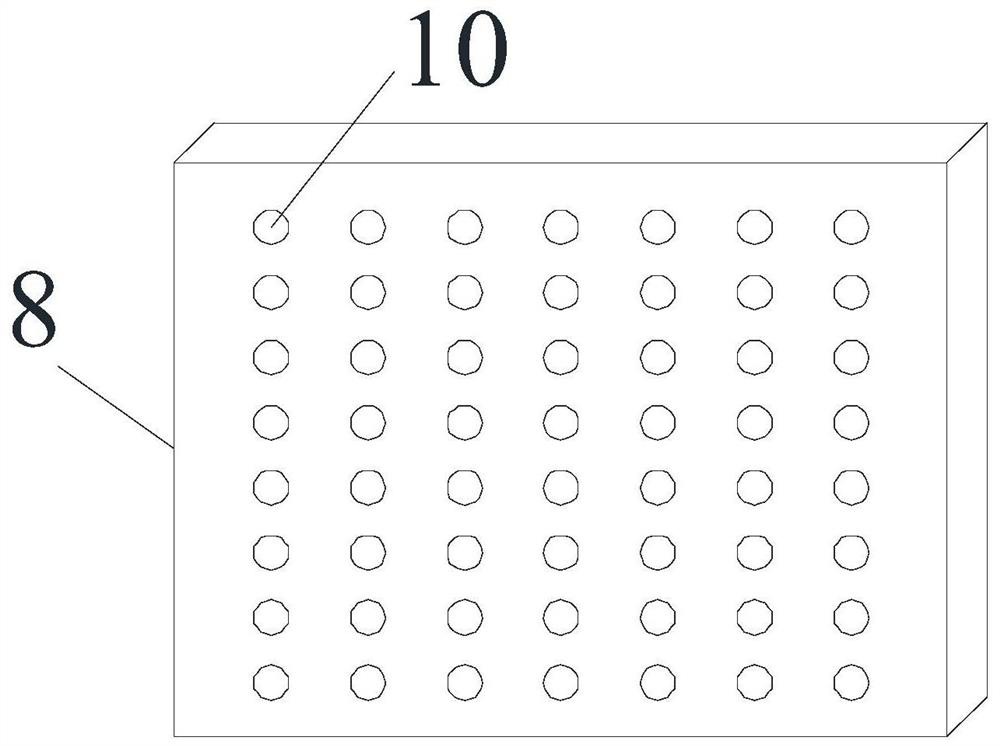

[0043] combine Figure 1 to Figure 5 As shown, the present invention is a true triaxial direct shear test box for simulating a force-heat-liquid coupling environment, including a test piece bin and a direct shear box. A large-size concrete shear block 13 and a shear sample 14 are arranged inside the specimen chamber. The shear sample 14 is embedded in the middle of the two concrete shear blocks 13, and the distance between the two concrete shear blocks 13 is 10 mm.

[0044] The direct shear box includes a sealing gland device, a loading head device, a sliding platen device, a hydraulic device and a heating device. The sealing glan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com