Silver nanoflower composite graphene SERS substrate, preparation method and application thereof

A composite graphene and silver nanotechnology, applied in the field of SERS substrate, can solve problems such as complexity, waste of production raw materials, environmental pollution, etc., and achieve the effect of increasing the density of hot spots, increasing the specific surface area, and controlling the growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

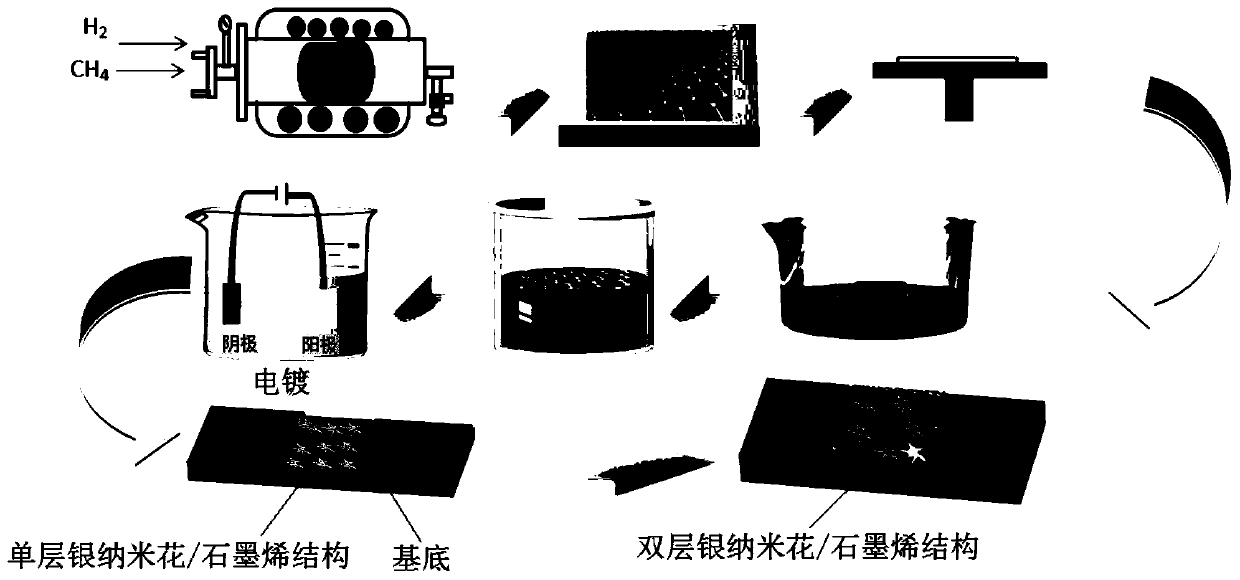

[0045] refer to figure 1 , a preparation method of silver nanoflower composite graphene SERS substrate, comprising the steps of:

[0046] 1, the preparation of graphene film, comprises the steps:

[0047] (1) Cleaning of copper foil: first use acetone, hydrochloric acid (HCl: H 2 O=1:20) wash three times; then wash three times with deionized water;

[0048] (2) Put the cleaned copper foil in the quartz tube, when the vacuum degree in the quartz tube reaches 3×10 -3 During Torr, the flow rate of hydrogen is 50 sccm, and when the temperature in the quartz tube rises to 1000°C, then the flow rate of methane is 50 sccm. After the quartz tube is cooled to room temperature, a copper foil with a graphene film is obtained; the purity of the methane and hydrogen is higher than 99.99%;

[0049] (3) the copper foil that is attached to the graphene film obtained in step (2) is placed and cut into some small pieces of 15mm * 10mm, then it is put into the ferric chloride solution of 0.2...

Embodiment 2

[0055] refer to figure 1 , a preparation method of silver nanoflower composite graphene SERS substrate, comprising the steps of:

[0056] 1, the preparation of graphene film, comprises the steps:

[0057] (1) Cleaning of copper foil: first use acetone, hydrochloric acid (HCl:H 2 O=1:20) wash three times; then wash three times with deionized water;

[0058] (2) Put the cleaned copper foil in the quartz tube, when the vacuum degree in the quartz tube reaches 3×10 -3 During Torr, the flow rate of hydrogen is 50 sccm, and when the temperature in the quartz tube rises to 1000°C, then the flow rate of methane is 50 sccm. After the quartz tube is cooled to room temperature, a copper foil with a graphene film is obtained; the purity of the methane and hydrogen is higher than 99.99%;

[0059] (3) the copper foil that is attached to the graphene film obtained in step (2) is placed and cut into some small pieces of 15mm * 10mm, then it is put into the ferric chloride solution of 0.20...

Embodiment 3

[0065] refer to figure 1 , a preparation method of silver nanoflower composite graphene SERS substrate, comprising the steps of:

[0066] 1, the preparation of graphene film, comprises the steps:

[0067] (1) Cleaning of copper foil: first use acetone, hydrochloric acid (HCl:H 2 O=1:20) wash three times; then wash three times with deionized water;

[0068] (2) Put the cleaned copper foil in the quartz tube, when the vacuum degree in the quartz tube reaches 3×10 -3 During Torr, the flow rate of hydrogen is 50 sccm, and when the temperature in the quartz tube rises to 1000°C, the flow rate of methane is 50 sccm. When the methane is passed for 30 minutes, the flow of methane is stopped, and the hydrogen is turned off when the temperature in the quartz tube drops to 230°C. After the quartz tube is cooled to room temperature, a copper foil with a graphene film is obtained; the purity of the methane and hydrogen is higher than 99.99%;

[0069] (3) the copper foil that is attache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com