A kind of flavoring capsule and its preparation and application

A technology of capsules and essences, which is applied in the tobacco industry and can solve problems such as complicated preparation methods and narrow application ranges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Weigh 12g of polyvinyl alcohol and dissolve it in 400mL of deionized water at 80°C to obtain a polyvinyl alcohol solution.

[0079] Weigh 3g of polylactic acid particles and dissolve in 30mL of dichloromethane to obtain a polylactic acid solution.

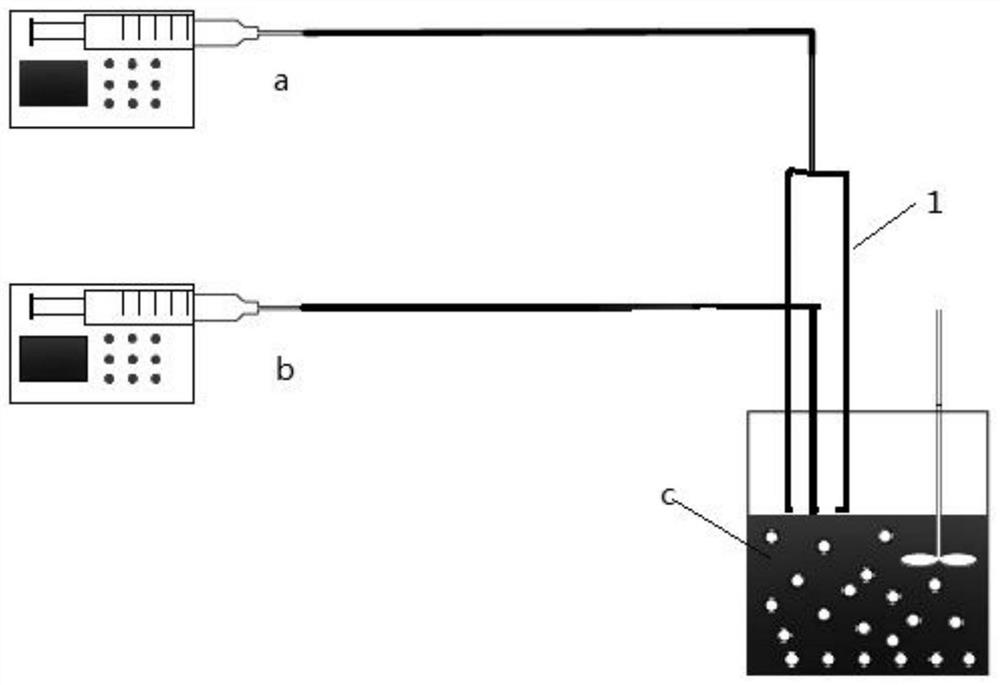

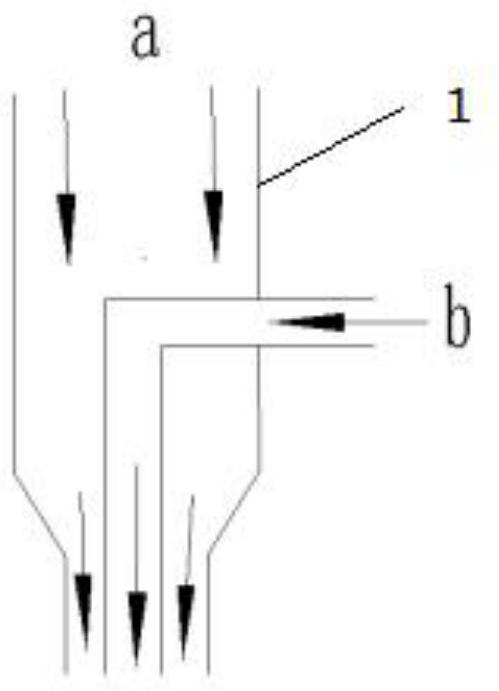

[0080] The polylactic acid solution and the maltol aqueous solution (the concentration of maltol is 1% mass fraction) were respectively loaded into syringes, placed on two syringe pumps, connected to the coaxial double-needle reactor, and the flow rates of the two syringe pumps were 5mL / h (maltol aqueous solution), 8mL / h (polylactic acid solution), drop into the polyvinyl alcohol solution, mechanically stir for 6h, the stirring speed is 250r / min, filter the product under reduced pressure, wash with deionized water, and then collect , to obtain polylactic acid flavored capsules. The particle size of the capsules was measured to be 3 mm.

Embodiment 2

[0082] Weigh 12g of polyvinyl alcohol and dissolve it in 400mL of deionized water at 80°C to obtain a polyvinyl alcohol solution.

[0083] Weigh 3.6g of polylactic acid particles and dissolve in 30mL of dichloromethane to obtain a polylactic acid solution.

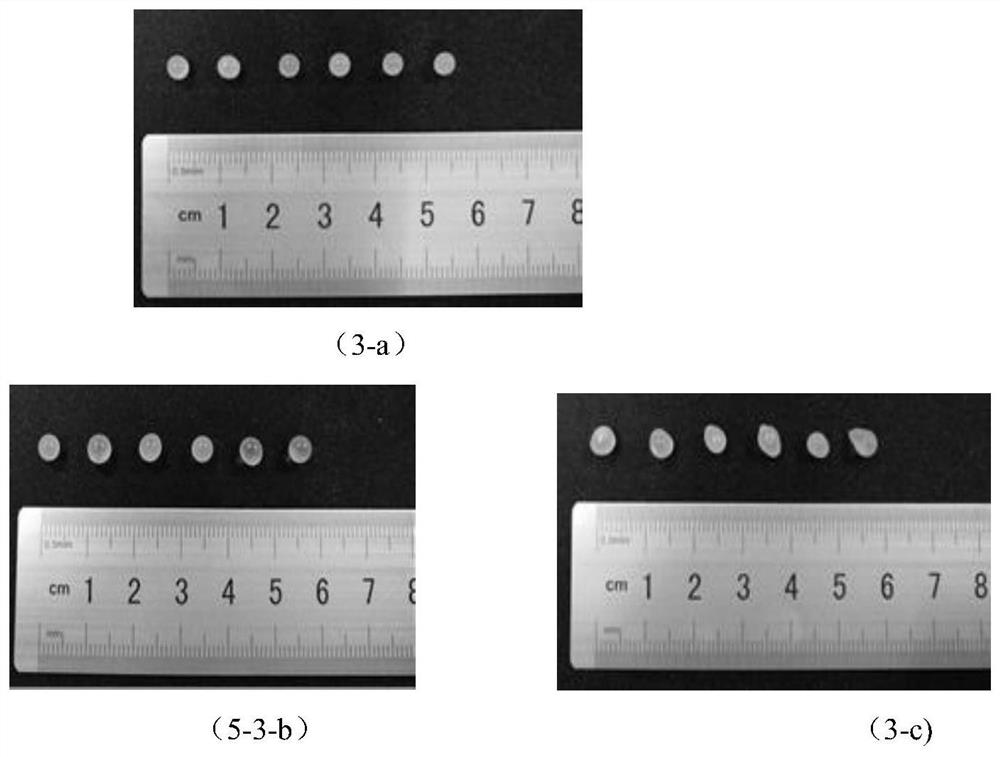

[0084] Put the polylactic acid solution and deionized water into syringes respectively, place them on two syringe pumps, connect the coaxial double-needle reactor, and the flow rates of the two syringe pumps are 5mL / h (deionized water) and 8mL / h respectively. (polylactic acid solution), drop into the polyvinyl alcohol solution, mechanically stir for 6 hours, the stirring speed is 250r / min, the product is filtered under reduced pressure, washed with deionized water, and then collected to obtain water-in-polylactic acid capsules. The particle diameter that records water-packed capsule is 3.2mm (see image 3 -a). The average amount of water contained in the capsules is 25.1 mg (water accounts for 73 wt% of the weight of the...

Embodiment 3

[0086] Weigh 12g of polyvinyl alcohol and dissolve it in 400mL of deionized water at 80°C to obtain a polyvinyl alcohol solution.

[0087] Weigh 4.5g of polylactic acid particles and dissolve in 30mL of dichloromethane to obtain a polylactic acid solution.

[0088] Put the polylactic acid solution and deionized water into syringes respectively, place them on two syringe pumps, connect the coaxial double-needle reactor, and the flow rates of the two syringe pumps are 5mL / h (deionized water) and 8mL / h respectively. (polylactic acid solution), drop into the polyvinyl alcohol solution, mechanically stir for 6 hours, the stirring speed is 250r / min, filter the product under reduced pressure, wash with deionized water, and then collect to obtain polylactic acid-in-water capsules. The particle size of the water-packed capsule is about 4mm (see image 3 -b), the average capsule water content is 35.3mg (water accounts for 63% of the capsule weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com