Outage continuous cooking cast iron electric rice cooker and casting process thereof

An electric rice cooker and cast iron technology, which is applied in the field of continuous cooking cast iron rice cooker and its casting technology after power failure, and achieves the effects of strong heat collection and energy storage, fast heating and long heat preservation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

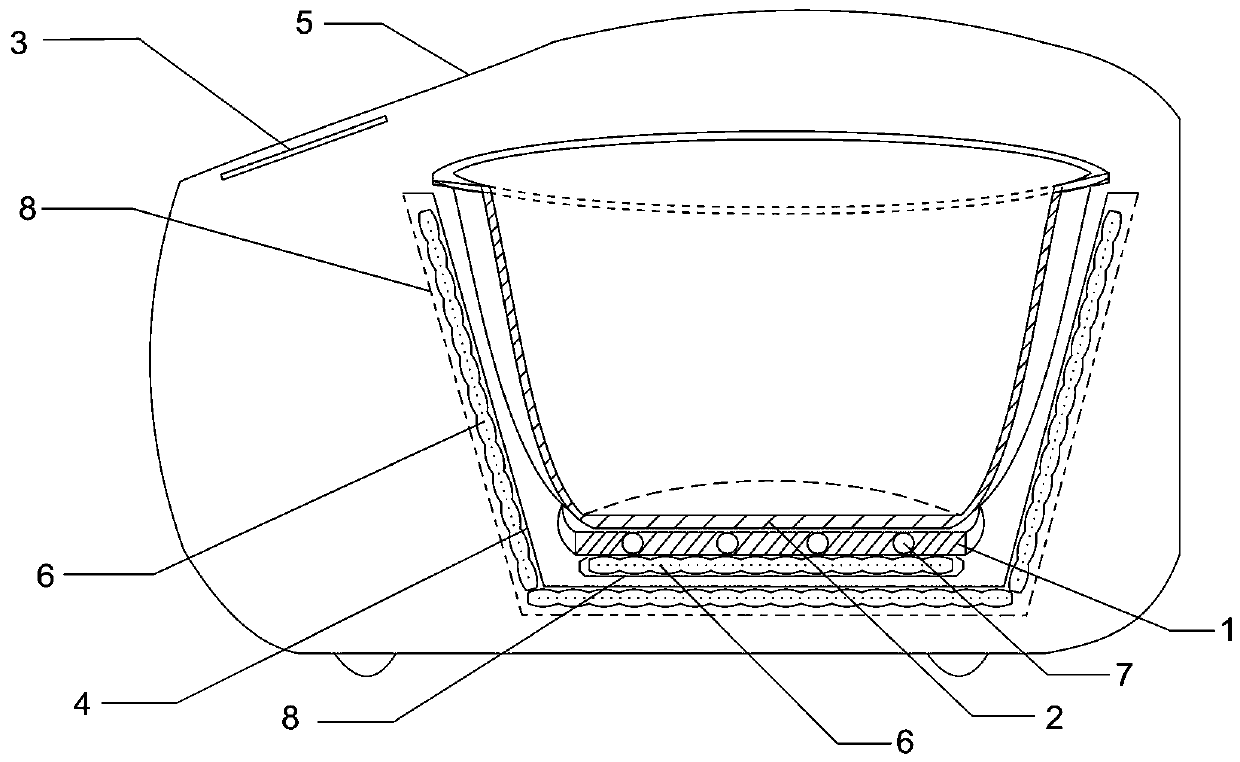

[0025] Embodiment 1: Referring to Fig. 1, a cast iron electric rice cooker for continuous cooking after power failure includes an outer shell, an insulating layer, a cast iron heating plate, a cast iron liner, and an intelligent control system for function keys, wherein the outer shell 5 is provided with an insulating Layer 4 and shell 5 are made of plastic or plastic steel structure. The insulation layer 4 is wrapped with insulation cotton 6 and metal foil film 8 to achieve heat insulation and constant temperature. The cast iron heating plate 1 is cast by melting and casting pig iron metal materials. The cast iron heating plate 1 contains a resistance wire heating tube 7, and the bottom of the cast iron heating plate 1 is wrapped with thermal insulation cotton 6 and a metal foil film 8. The cast iron inner tank 2 is smelted and cast with pig iron. Car processing, two times of spraying ceramic glaze and two times of sintering, each function key control circuit of the function k...

Embodiment 2

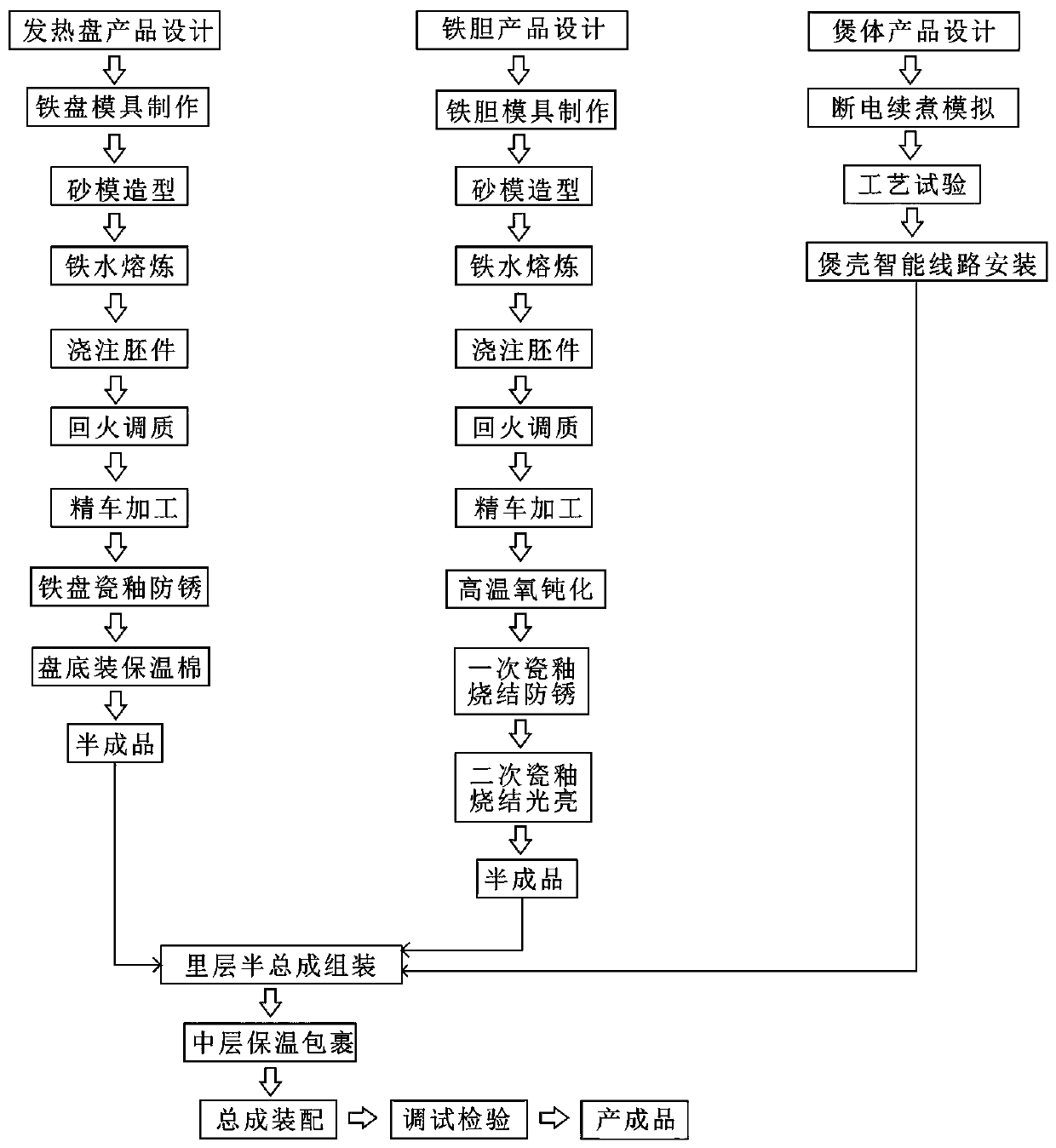

[0029] Embodiment 2: refer to figure 2 As shown, the production process steps of the cast iron heating plate 1 are as follows:

[0030] ①Pig iron smelting: use pig iron metal material to smelt at high temperature into molten iron for casting. The temperature of molten iron is about 1600°C, and the harmful elements will be burned at high temperature during smelting;

[0031] ② Pouring blank: when the temperature of the molten iron is lowered to 1400°C, it is poured twice, including the resistance wire heating tube (7) in the cast iron heating plate, which is beneficial to the heat absorption and heat collection function of the cast iron plate;

[0032] ③Tempering and tempering: the cast iron heating plate blank is subjected to high temperature 800°C physical performance tempering to prevent deformation;

[0033] ④Finish turning processing: For the cast iron heating plate blank, after finishing turning, the thickness of the cast iron heating plate is 13-15mm, which is benefici...

Embodiment 3

[0035] Embodiment 3: refer to figure 2 As shown, the production process steps of the cast iron liner 2 are as follows:

[0036] ①Pig iron smelting: use pig iron metal material to smelt at high temperature into molten iron for casting. The temperature of molten iron is about 1600°C, and the harmful elements will be burned at high temperature during smelting;

[0037] ② Pouring blank: When the molten iron cools down to 1450°C, it is poured into shape at one time;

[0038] ③Tempering and tempering: 800°C high-temperature physical performance quenching and tempering of cast iron liner blanks to prevent deformation;

[0039] ④Finish turning processing: the blank of the cast iron liner is processed by finish turning to ensure that the thickness of the side wall of the liner is 2~2.2mm, and the thickness of the bottom wall of the liner is 3.5~3.8mm, which is conducive to a large amount of heat collection and energy storage of the cast iron liner. It is beneficial to the three-dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com