Grass cutter intelligence control system

An intelligent control system and lawn mowing robot technology, applied in the direction of lawn mowers, cutters, harvesters, etc., can solve the problems of pollution, high labor intensity, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

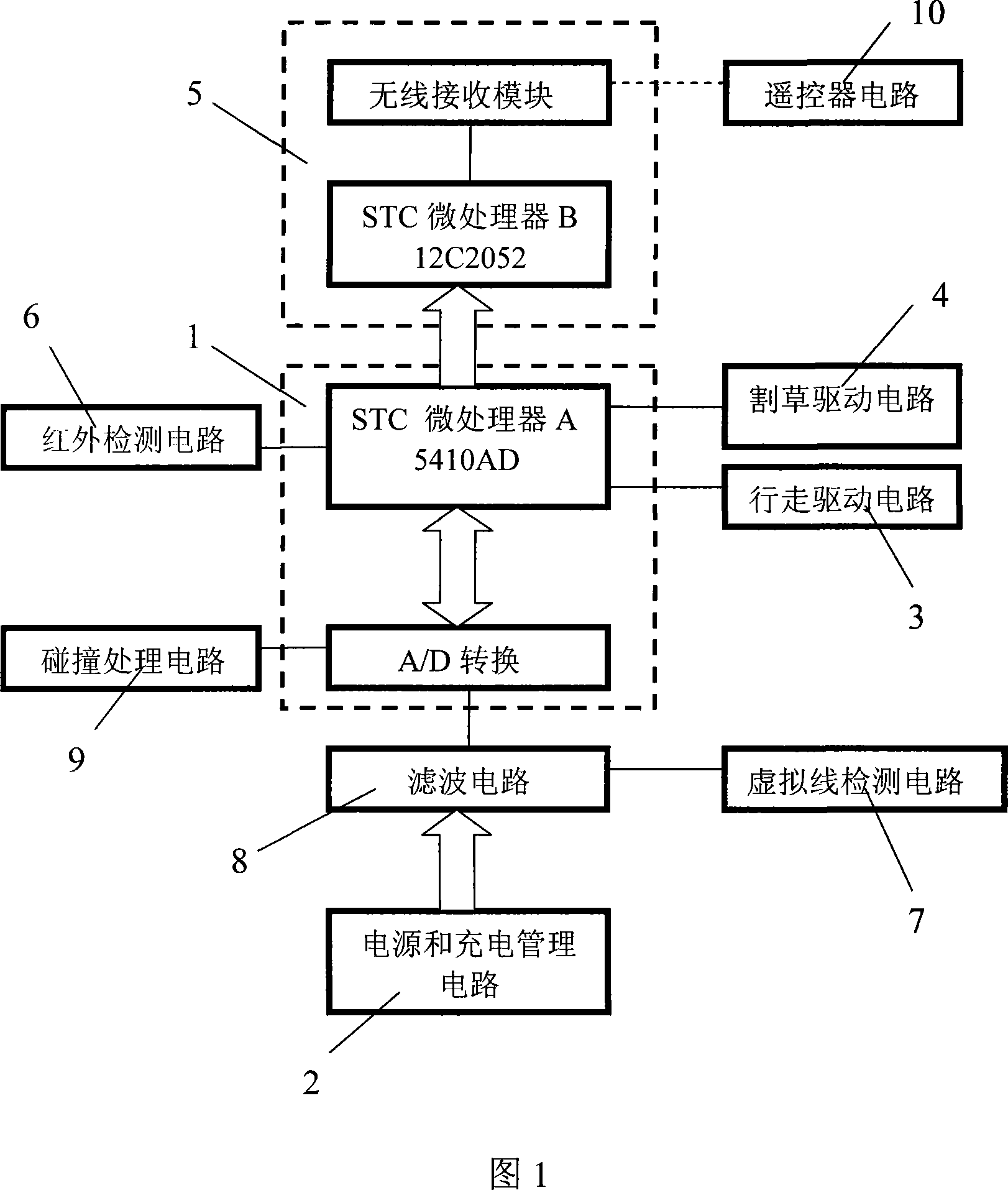

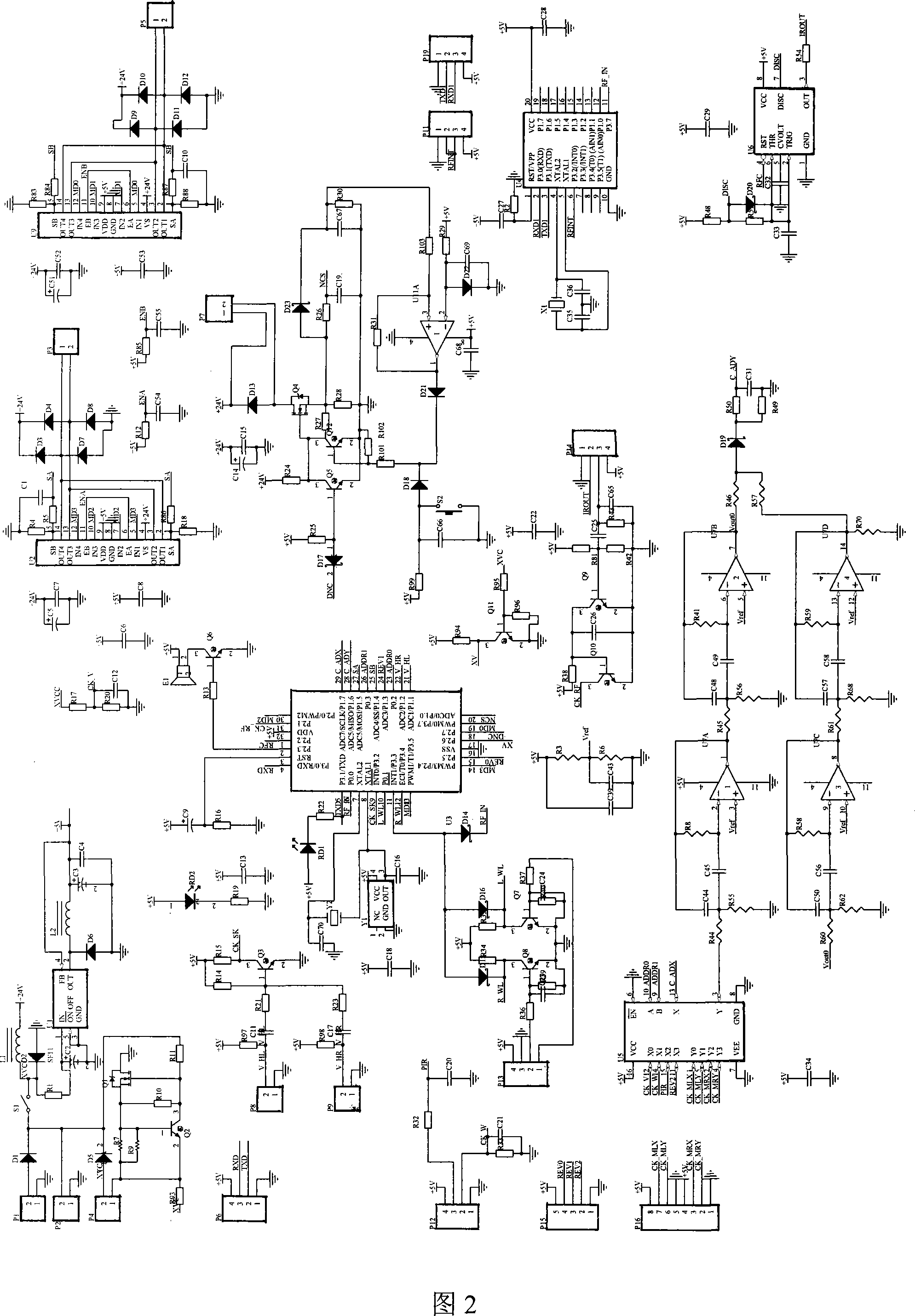

[0022] Referring to Fig. 1 and Fig. 2, this embodiment includes a motherboard circuit processor unit 1, a power supply and charging management circuit 2, a walking drive circuit 3, a mowing drive circuit 4, a remote control receiving circuit 5, an infrared detection circuit 6, and a virtual line detection circuit 7. Filter circuit 8, collision processing circuit 9, remote control circuit 10. Wherein the motherboard circuit processor unit 1 includes a microprocessor A with A / D conversion pins.

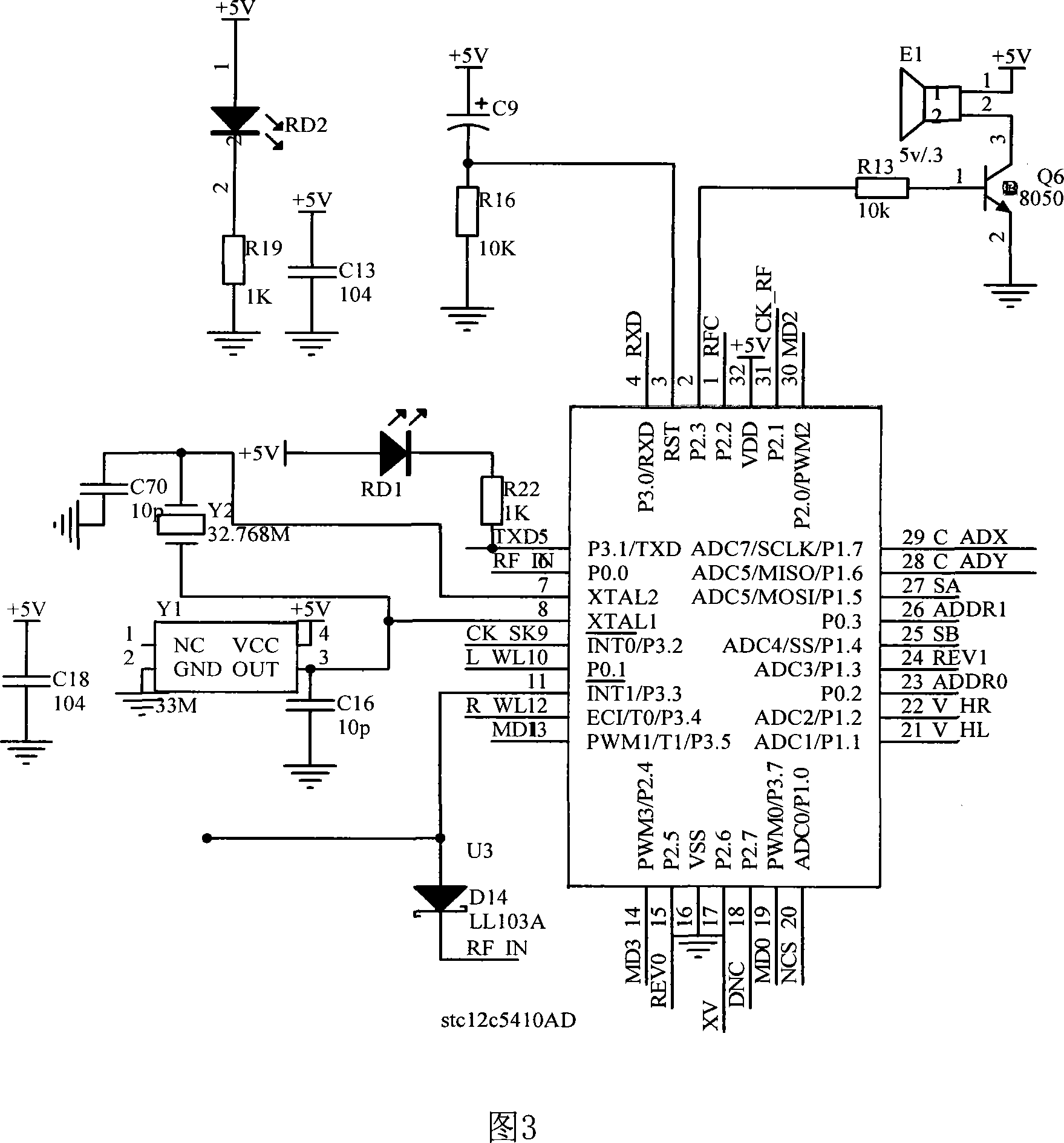

[0023] Referring to FIG. 3 , the microprocessor A in the processor unit of the mainboard circuit is an STC microprocessor (hereinafter referred to as U3) with a model number of 5410AD. The pin 7 and pin 8 of the microprocessor U3 are connected with a crystal oscillator clock circuit composed of crystal oscillator Y1, capacitor C16, and capacitor C70 (the crystal oscillator Y2 reserves a vacancy for convenient standby), which provides the working clock for the microprocessor U3; Pin 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com