Mining nut dismounting device and using method

A nut and mining technology, applied in the field of mining nut disassembly and assembly devices, can solve the problems of low safety factor and unreliable installation, and achieve the effect of improving disassembly and assembly efficiency, avoiding unreliable installation and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

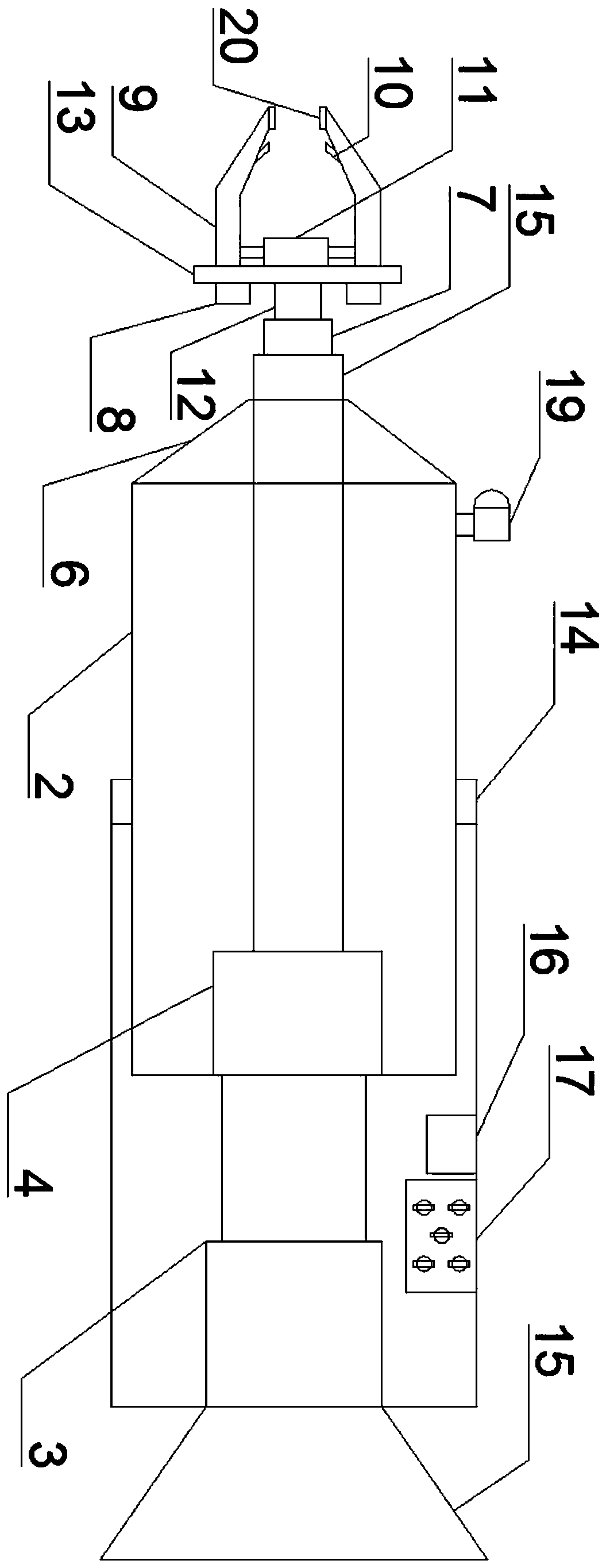

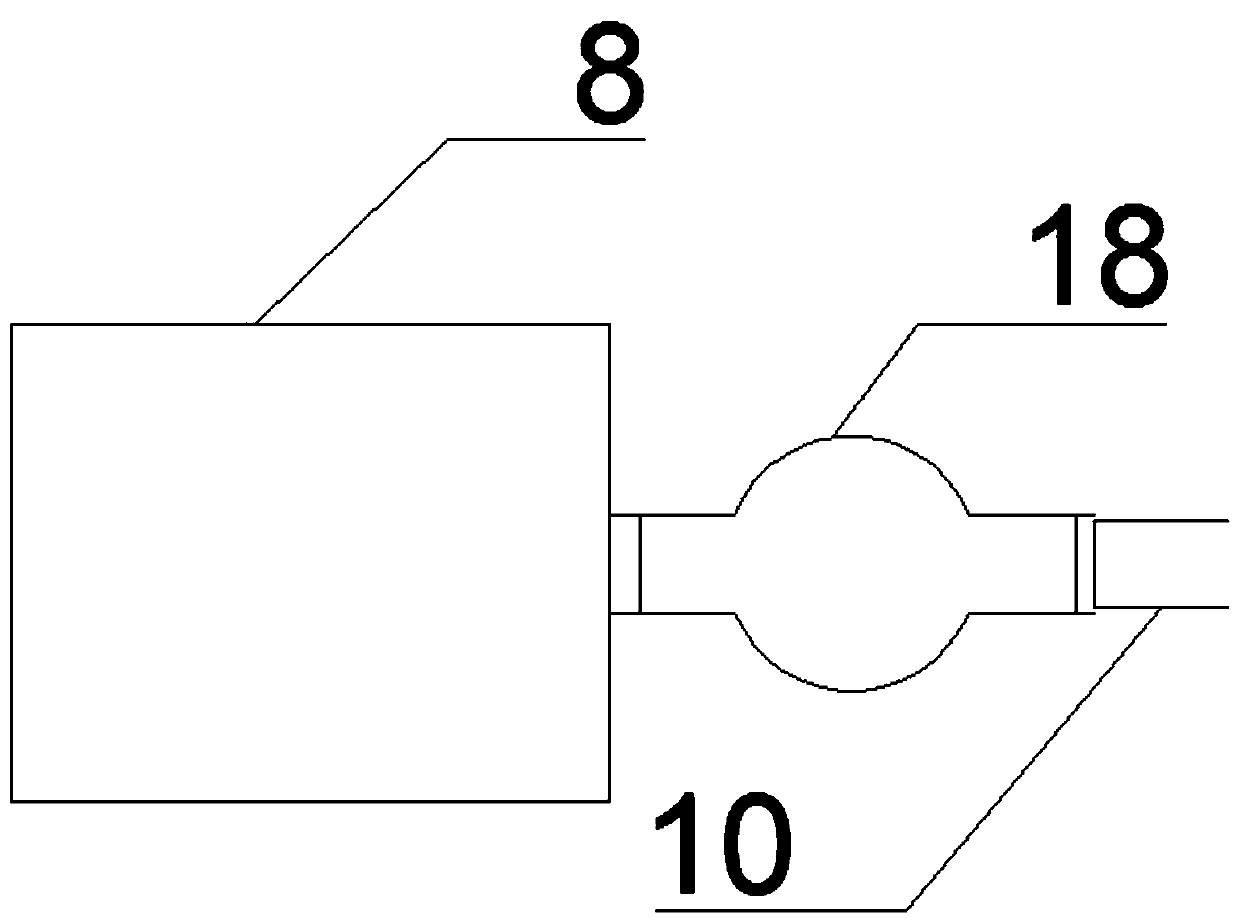

[0020] Such as figure 1 As shown, a mining nut dismounting device includes a housing 1, a movable housing 2 is slidably connected to the inner side wall of the housing 1, and a motor 4 is fixedly installed inside the movable housing 2. The bottom end of the movable housing 2 is fixedly equipped with a hydraulic telescopic rod 3, the other end of the hydraulic telescopic rod 3 is fixedly connected with the housing 1, the head of the movable housing 2 is fixedly installed with a butt joint 6, and the movable The head of the housing 2 is fixedly installed with a bearing sleeve 5 extending out of the butt joint 6, the output shaft of the motor 4 runs through the bearing sleeve 5, the output shaft of the motor 4 is connected with a torque sensor 7, and the torque sensor 7 A clamping mechanism is installed on the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com