Turnover appliance for automobile fuel tank

A technology for fuel tanks and appliances, which is applied in the field of auto parts appliances and turnover automobile fuel tank appliances, which can solve the problems of low reuse rate, low work efficiency, inconvenient access, etc., and reduce transportation and storage costs and space The effect of improving utilization rate and saving transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

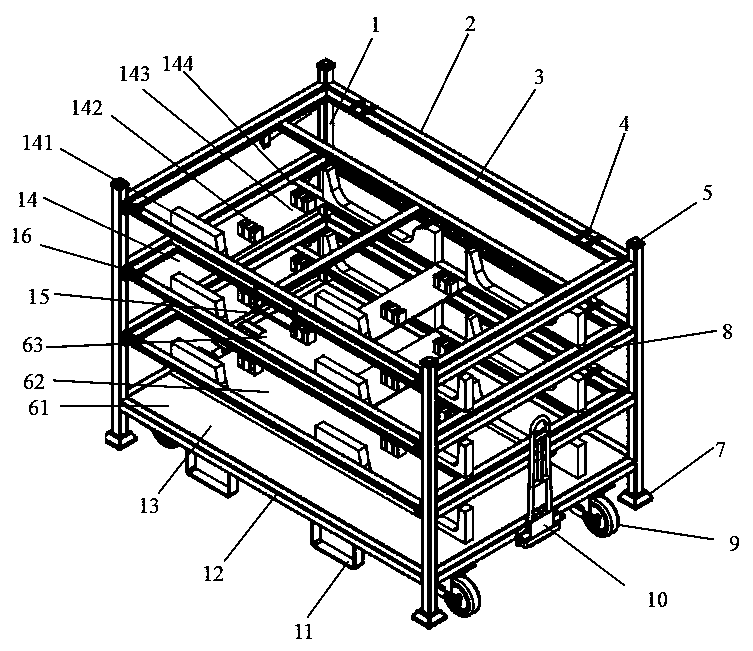

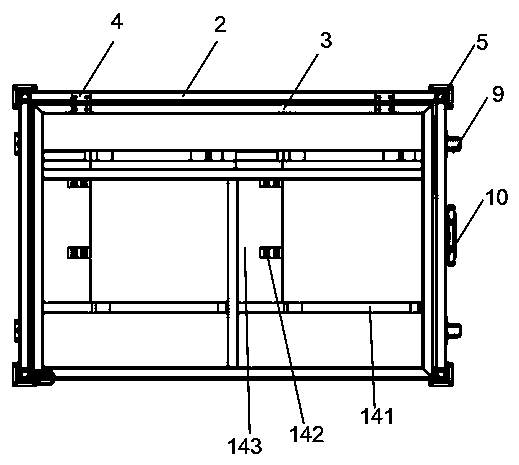

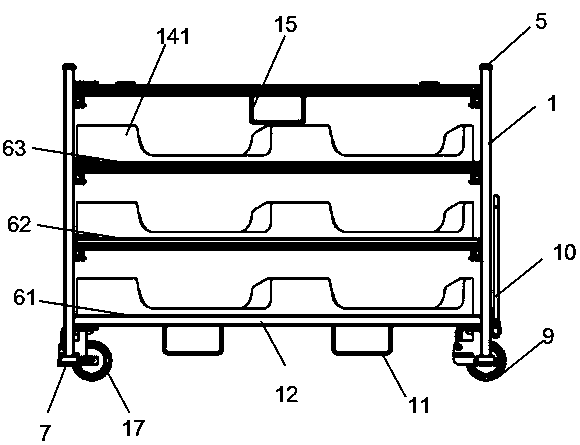

[0042] Combine below Figure 1-Figure 9 To describe in detail the specific working conditions proposed by the present invention, an appliance for revolving automobile fuel tanks includes an appliance body and a supporting platform.

[0043] The main body of the appliance is welded to the main column 1 by the top beam 2 on the side and the back, the middle beam 8 is welded to the main column 1, and the bottom beam 12 is welded to the main column 1. There are four main columns 1, and the material is Q235. It is a rectangular square tube, and the stacking top bowl 5 is welded on the top of the main column 1, and the stacking bottom bowl 7 is welded on the bottom end. When the appliance is transported or stored, it realizes the stacking function, so as to increase the space utilization without damaging the fuel of the vehicle. Box 20, top beam 2, middle beam 8 and bottom beam 12 are made of Q235 and shaped as rectangular square tubes. Two forklift feet 11 are respectively welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com