An exploit based on mil-101 (cr 3+ ) metal organic framework material adsorption method for organic dyes in water

A metal-organic framework, organic dye technology, applied in the direction of adsorption of water/sewage treatment, water pollutants, alkali metal compounds, etc., to achieve great application potential and industrial value, simple preparation process, and obvious adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

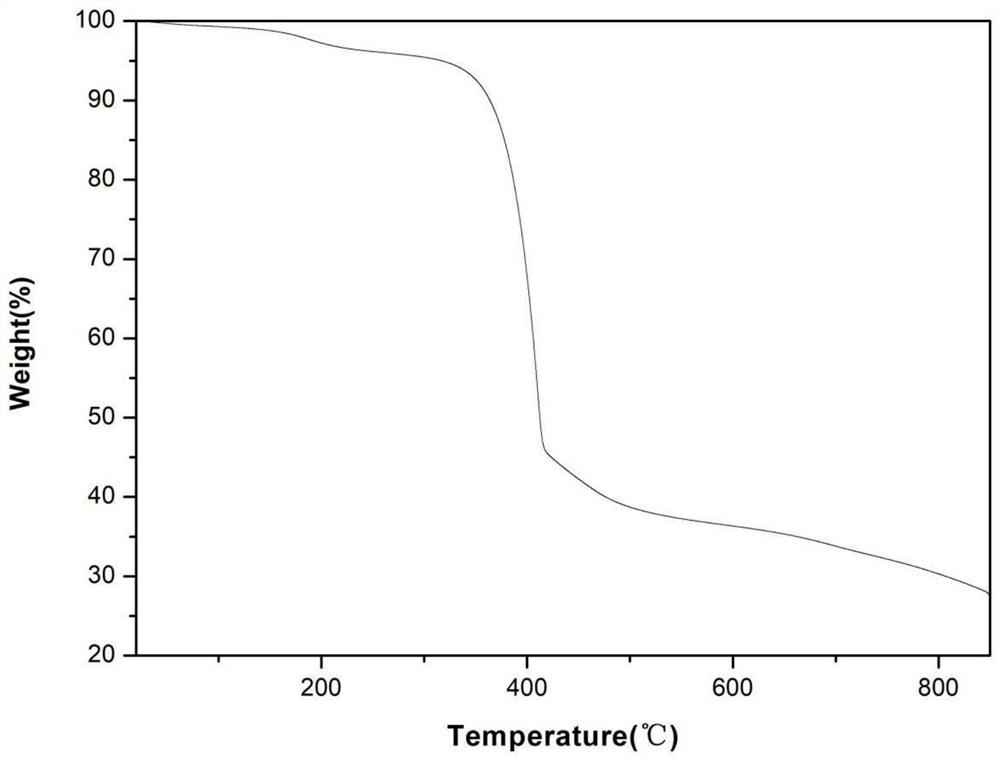

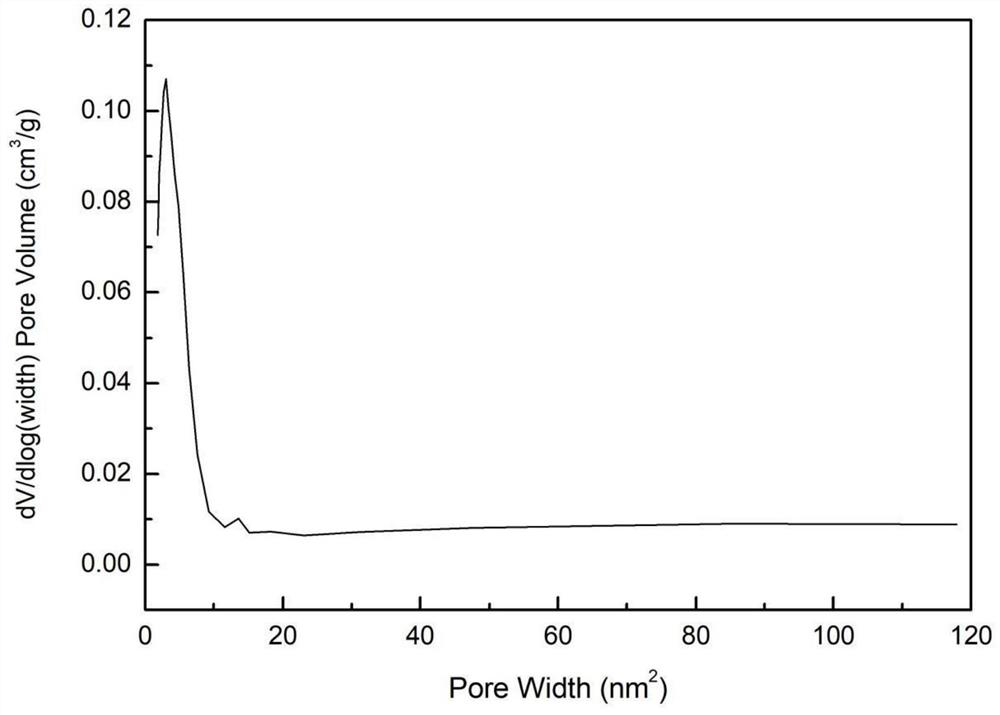

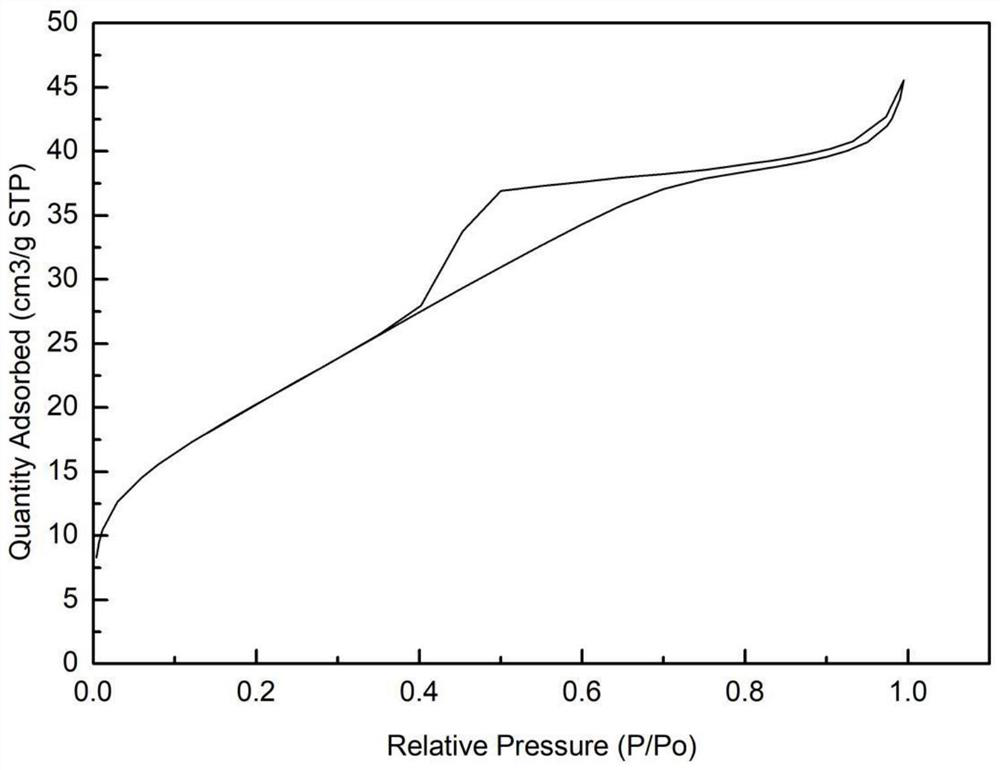

[0028] Based on MIL-101 (Cr 3+ ) type mesoporous-microporous metal-organic framework materials:

[0029] Dissolve (0.0821g, 1mmol) 2-methylimidazole in 20ml of high-purity water, stir at room temperature for 5min; slowly add (0.5401g, 2mmol) Azobenzene-4-4'dicarboxylic acid into 2-methylimidazole solution, and Continue stirring for 25min; then (0.8003g, 2mmol) Cr(NO 3 ) 3 9H 2 O was added to the stirred mixed solution, stirred at room temperature for 15 min, and the solution was black and turbid. The obtained mixed solution was transferred to a 30ml polytetrafluoroethylene-lined stainless steel reaction kettle, and placed in an oven at 170°C for 24 hours. The reactor was naturally cooled to room temperature, the obtained precipitate was centrifuged, washed three times with absolute ethanol, then washed three times with high-purity water, and dried at 80°C for 15 hours to obtain a product based on MIL-101 (Cr 3+ ) type of mesoporous-microporous metal-organic framework mate...

Embodiment 2

[0035] Dissolve (0.0821g, 1mmol) 2-methylimidazole in 20ml of high-purity water and stir for 5min; slowly add (0.5401g, 2mmol) Azobenzene-4-4'dicarboxylic acid into the 2-methylimidazole solution and continue stirring 25min; Then (0.8003g, 2mmol) Cr(NO 3 ) 3 9H 2 O was added to the stirred mixed solution and stirred for 15 min, the solution was black and turbid. The obtained mixed solution was transferred to a 30ml polytetrafluoroethylene-lined stainless steel reaction kettle, and placed in an oven at 160°C for 24 hours.

Embodiment 3

[0037] Dissolve (0.0821g, 1mmol) 2-methylimidazole in 20ml of high-purity water and stir for 5min; slowly add (0.5401g, 2mmol) Azobenzene-4-4'dicarboxylic acid into the 2-methylimidazole solution and continue stirring 25min; Then (0.8003g, 2mmol) Cr(NO 3 ) 3 9H 2 O was added to the stirred mixed solution and stirred for 15 min, the solution was black and turbid. The obtained mixed solution was transferred to a 30ml polytetrafluoroethylene-lined stainless steel reaction kettle, and placed in an oven at 150°C for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com