Sulfur autotrophic denitrification sludge granulation and sulfur mud separation device and operation method thereof

A denitrification sludge and separation device technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as lack of electron acceptors, lack of electron donors, and high cost of carbon sources , to achieve the effect of not easy to suck back, stable air pressure, and reduce aeration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

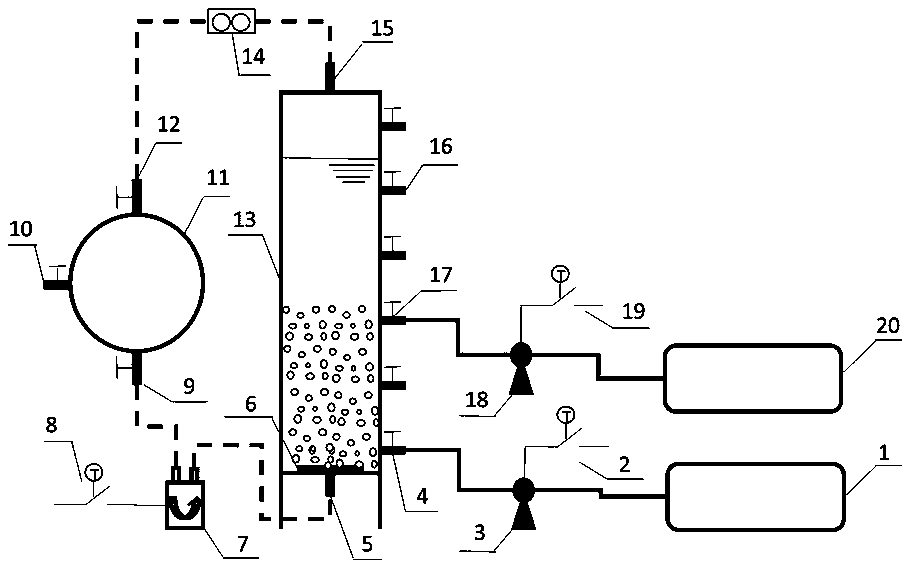

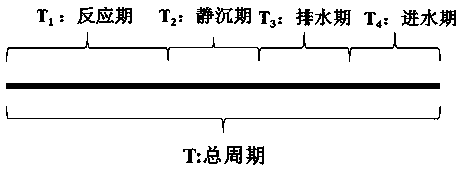

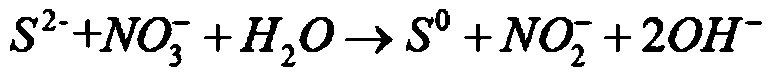

[0038] The invention relates to a sulfur autotrophic denitrification sludge granulation and sulfur sludge separation device, which comprises a closed reactor main body 13 , a three-hole air bag 11 , a water inlet tank 1 and a water outlet tank 20 . The top of the reactor main body 13 is provided with an air outlet 15, and the bottom is provided with an air inlet 5, and both the air outlet 15 and the air inlet 5 are respectively connected to the two air inlets and outlets of the three-hole air bag 11 through the air pipe. The side wall of the reactor main body 13 is provided with a water outlet 17 and a water inlet 4 sequentially from top to bottom, the water outlet 17 is connected to the water outlet tank 20 through a water pipe, and the water inlet 4 is connected to the water inlet tank 1 through a water pipe. The height-to-diameter ratio of the reactor body 13 can be 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com