Solidifying agent composition, manufacturing method thereof and eco-friendly structural material comprising the composition

A technology of structural material and curing agent, applied in the field of curing agent composition, can solve problems such as time and economic loss, and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

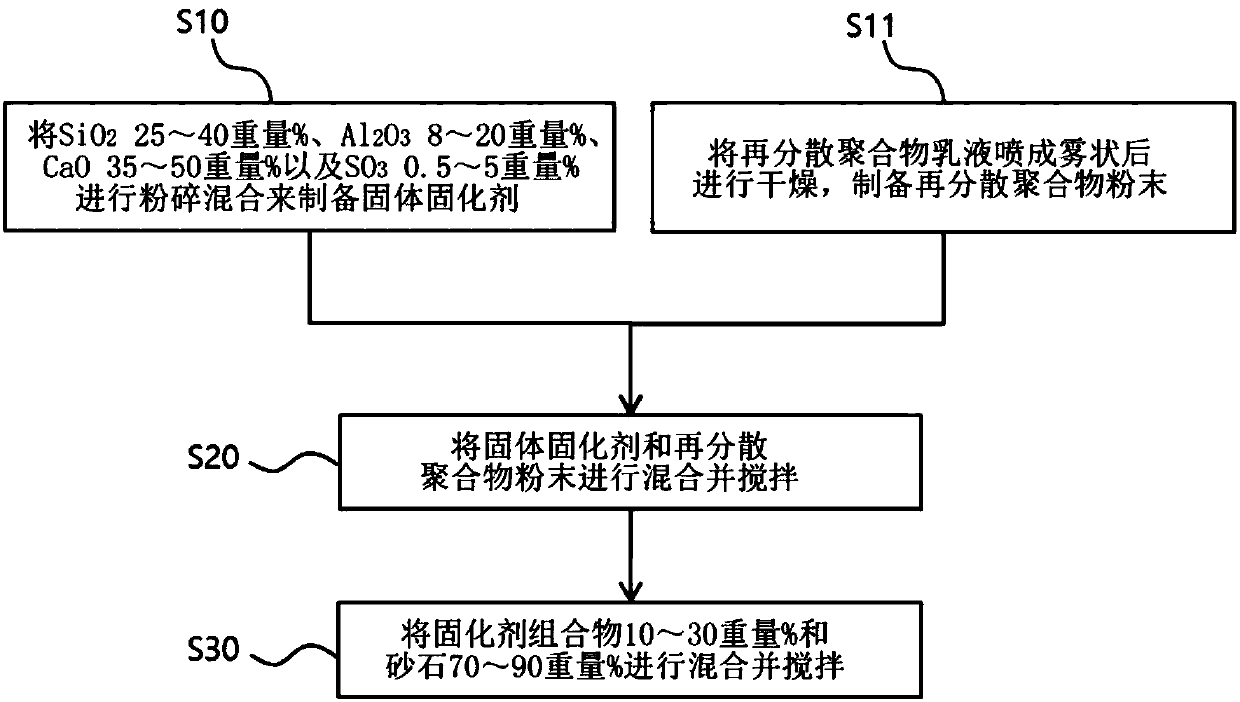

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: the preparation of solid curing agent

[0073] Limestone, silicate (Silicate), gypsum (Gypsum), and blast furnace slag (Blastfurnace slags) are charged into a silo, and crushed and mixed to prepare a solid curing agent. In detail, solid curing agents having the composition ratios in Table 1 and the fineness in Table 2 below were prepared, respectively.

[0074] [Table 1]

[0075]

[0076]

[0077] For reference, the minor components in Table 1 represent other impurities that are inevitably produced during the preparation of solid curing agents.

[0078] [Table 2]

[0079] distinguish Example a Example b Example c Example d Example e Fineness (cm 2 / g)

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com