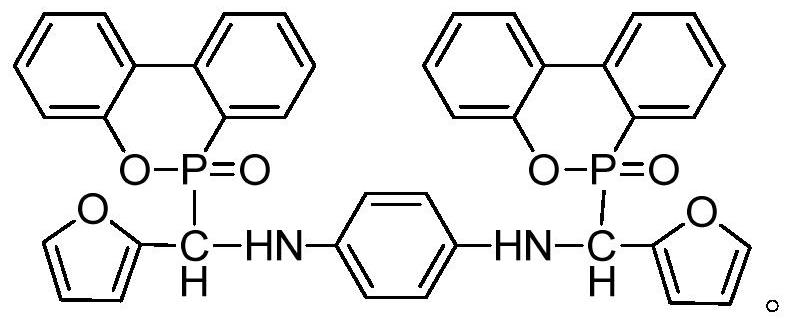

A kind of bio-based phosphaphenanthrene curing agent flame-retardant epoxy resin material and preparation method thereof

A technology of epoxy resin and curing agent, which is applied in the fields of chemical instruments and methods, organic chemistry, compounds of group 5/15 elements of the periodic table, etc., to improve physical and mechanical properties, good application prospects, improve impact resistance and fire protection The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

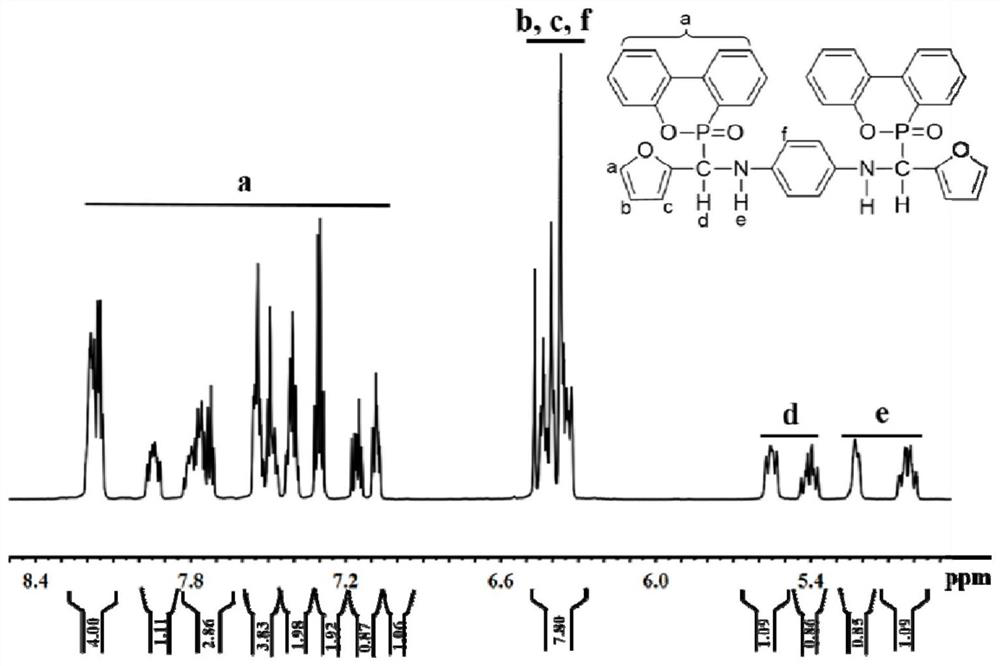

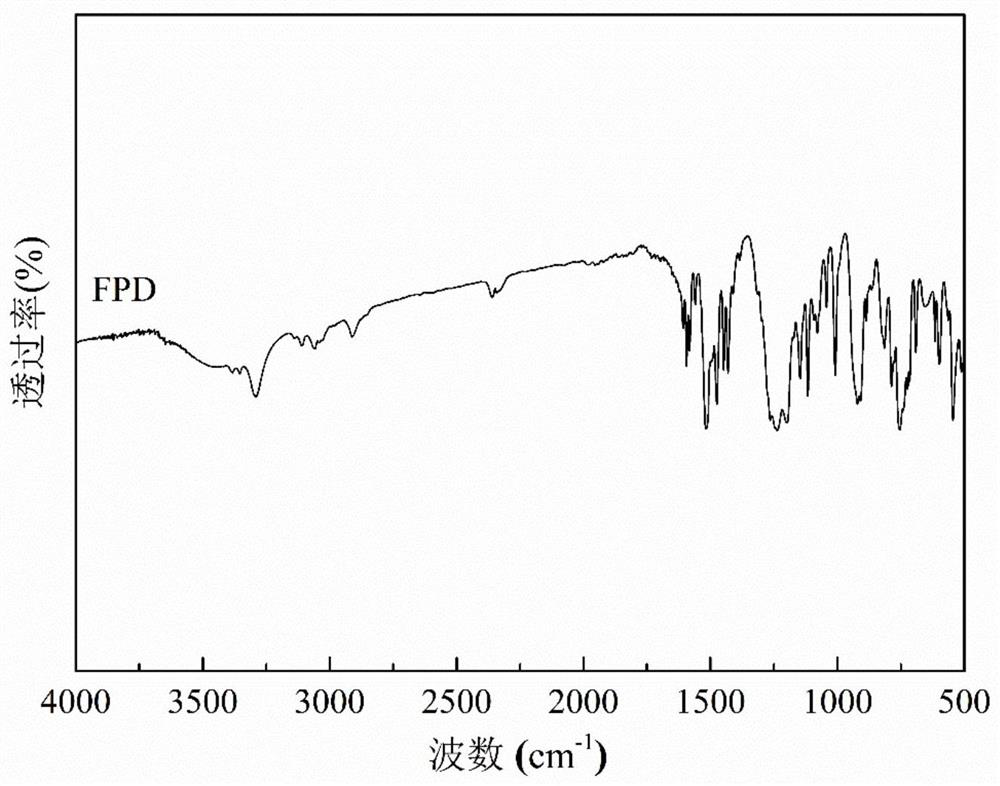

Method used

Image

Examples

Embodiment 1

[0026] Heat 100g of bisphenol A diglycidyl ether epoxy resin with an epoxy value of 0.46 to 120°C, add 3.88g of FPD, stir until the FPD is completely dissolved and the solution is transparent, add 37.90g of curing agent DDM, and stir After the DDM is completely dissolved, vacuum degassing at 120°C for 3 minutes, curing at 100°C for 2 hours, and then curing at 120°C for 4 hours, the prepared bio-based phosphaphenanthrene flame retardant curing agent flame retardant epoxy resin material The limiting oxygen index is 32.8%, and it has passed the UL94V-1 level, and the impact strength reaches 17.8kJ m -2 .

Embodiment 2

[0028] Heat 100g of bisphenol A diglycidyl ether epoxy resin with an epoxy value of 0.48 to 140°C, add 6.94g of FPD, stir until the FPD is completely dissolved and the solution is transparent, add 44.50g of curing agent DDM, and stir After the DDM is completely dissolved, vacuum degassing at 120°C for 3 minutes, curing at 120°C for 2 hours, and then curing at 170°C for 4 hours, the prepared bio-based phosphaphenanthrene flame retardant curing agent flame retardant epoxy resin material The limiting oxygen index is 33.6%, and it has passed the UL94V-0 level, and the impact strength reaches 15.6kJ m -2 .

Embodiment 3

[0030] Heat 100g of bisphenol A diglycidyl ether epoxy resin with an epoxy value of 0.49 to 160°C, add 7.98g of FPD, stir until the FPD is completely dissolved and the solution is transparent, add 37.31g of curing agent DDM, and stir until After the DDM is completely dissolved, vacuum degassing at 120°C for 3 minutes, curing at 140°C for 2 hours, and then curing at 180°C for 4 hours, the prepared bio-based phosphaphenanthrene flame retardant curing agent flame retardant epoxy resin material The limiting oxygen index is 33.9%, and it has passed the UL94V-0 level, and the impact strength reaches 18.9kJ m -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com