PPO/PA (poly phenylene oxide-polyamide) composite material and preparation method thereof

A composite material and material technology, which is applied in the field of PPO/PA composite material and its preparation, can solve the problems of product opacity and limit the application of transparency requirements, and achieve the effect of improving transparency and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

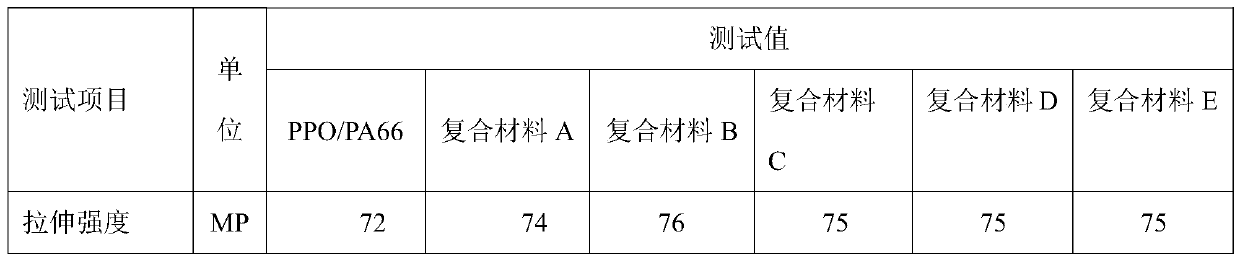

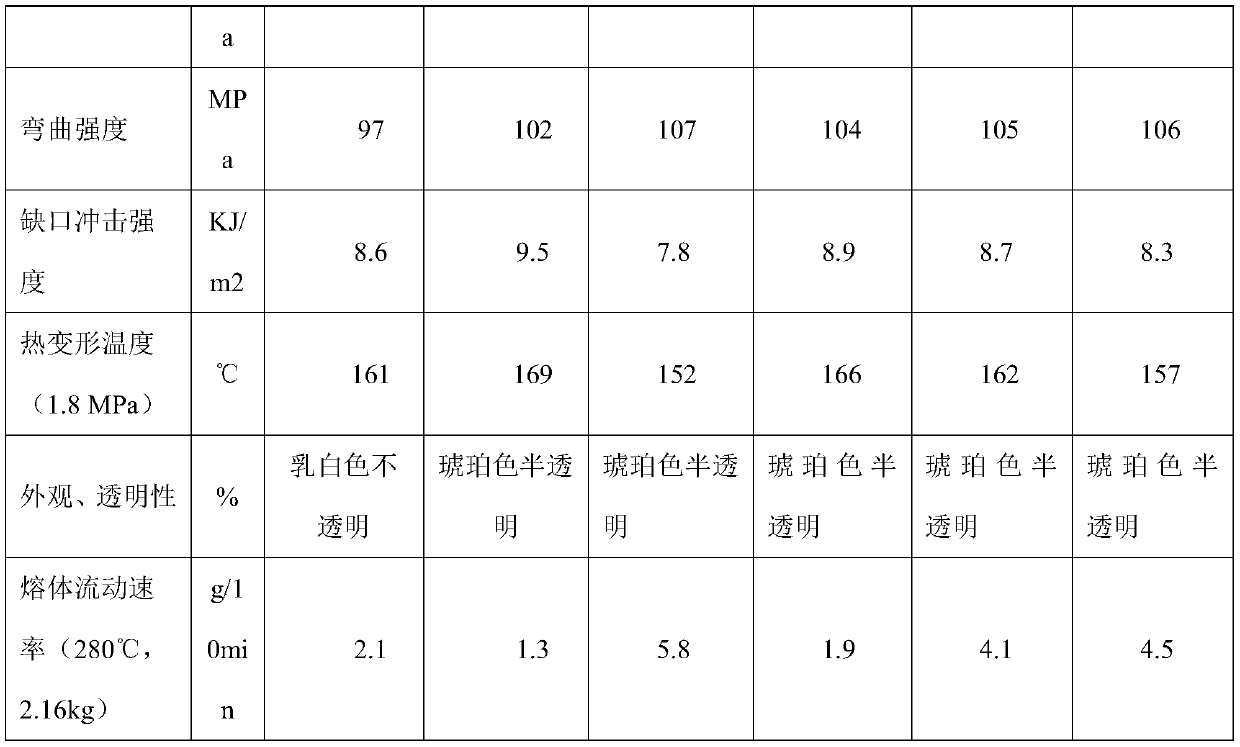

[0020] Embodiment: the product performance test of the composite material prepared by the present invention

[0021] 1. Composite material preparation

[0022] (1) Preparation of PPO / PA composite material A

[0023] Raw materials: 90 parts of PPO resin, 10 parts of PA6I resin, 0.2 parts of antioxidant, 2 parts of lubricant. (The mass ratio of PPO and PA6I is 9:1)

[0024] 1. Weigh 45 kg of PPO resin, 5 kg of dried PA6I resin, 0.1 kg of antioxidant, and 1 kg of lubricant, add them to a 500L-SHR high-speed mixer, mix at low speed for 1 minute, then mix at high speed for 2 minutes, and release materials;

[0025] 2. Feed the mixed material into the TE-35 twin-screw extruder, and after the material comes out of the extruder die, it will be cooled, blown dry, and pelletized to obtain the PPO / PA composite material .

[0026] The temperature of each zone of the twin-screw extruder is set as follows: the temperature in the first zone is 180-185°C, the temperature in the second zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com