Medium-temperature ageing thermal treatment method for stainless steel and vacuum furnace adopted by medium-temperature ageing thermal treatment method

An aging heat treatment and vacuum furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of damaging the corrosion resistance of products, weak oxidation layer reduction ability, and prone to oxidative discoloration, so as to achieve small equipment changes and avoid chemical The use of pickling solution and the effect of avoiding the pickling section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

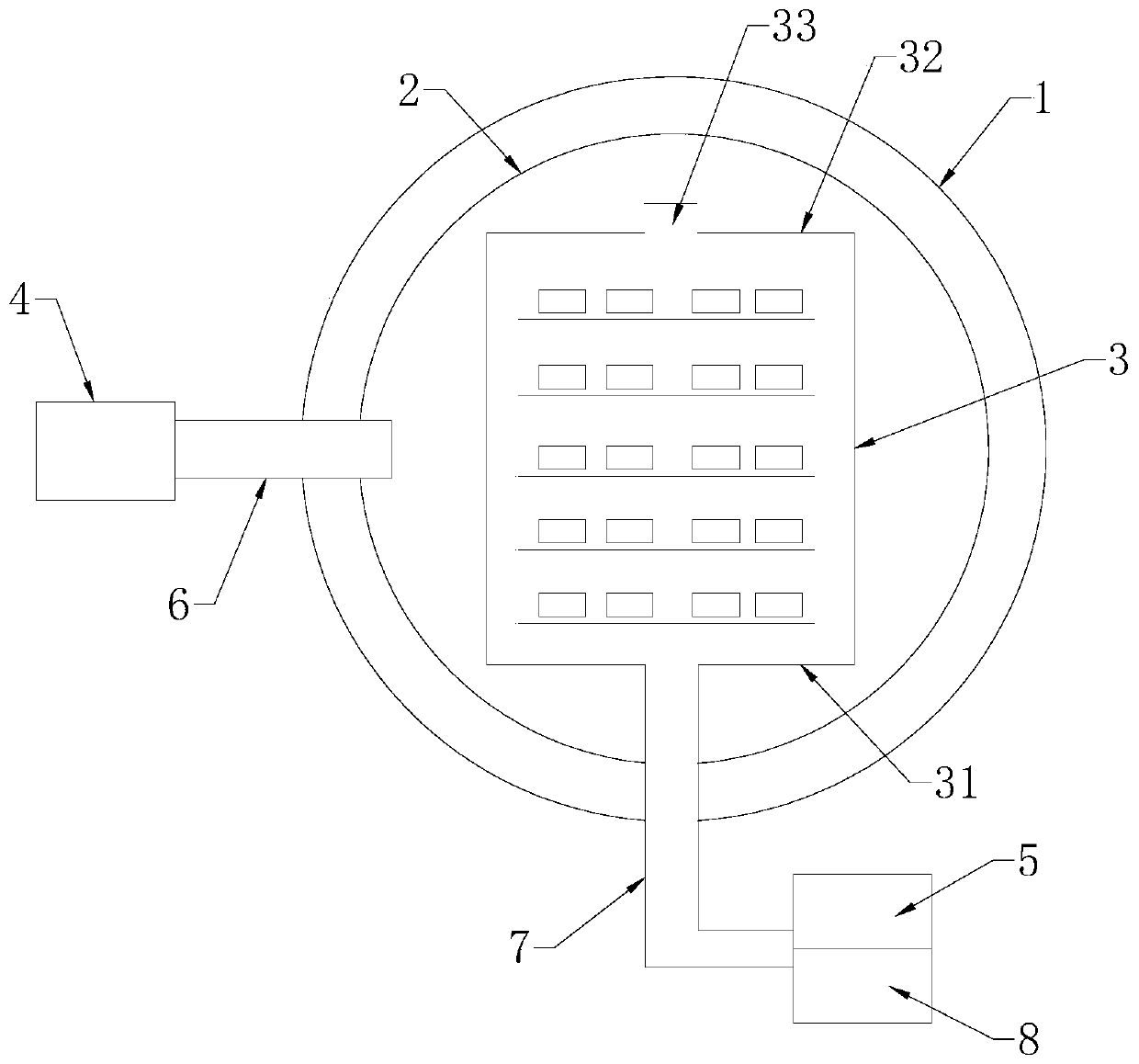

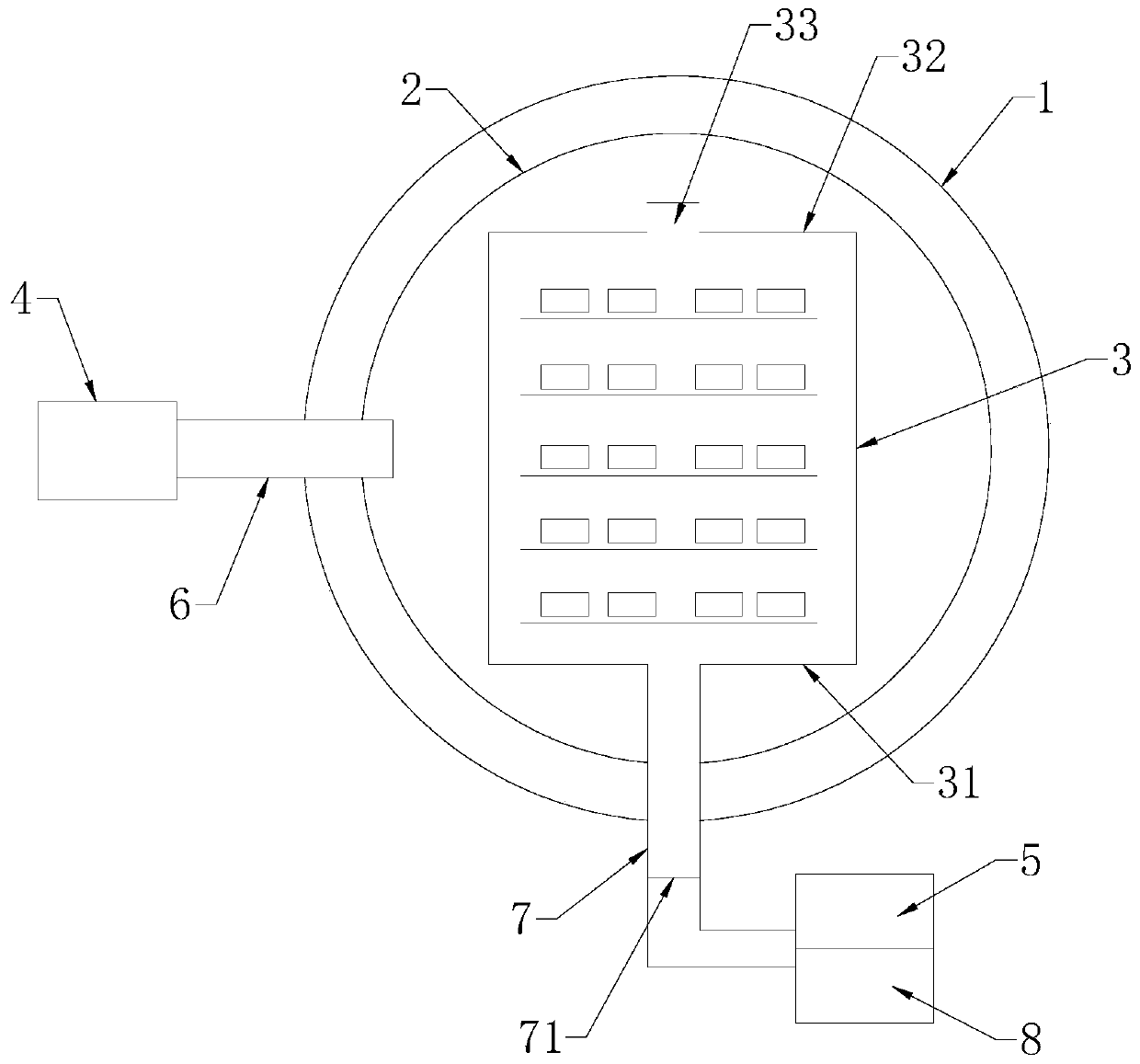

[0036] combine figure 1 with figure 2 As shown, a vacuum furnace for stainless steel medium-temperature aging heat treatment is preferably used as a vacuum batch furnace. The vacuum batch furnace includes a vacuum vessel 1 arranged as a horizontal cylindrical structure, and a carbon fiber is installed in the vacuum vessel 1. The insulation cylinder 2 made of felt material, the insulation cylinder 2 is also a cylindrical structure, and the insulation cylinder 2 is provided with a heat treatment box 3, and the chamber of the heat treatment box 3 is connected with the chamber of the insulation cylinder 2 Pass. MIM17-4PH stainless steel products are placed on the partition in the heat treatment box 3, and the heating operation is completed through the heating device of the vacuum vessel 1 itself, and an inert gas is introduced into the vacuum vessel 1 to create an inert gas atmosphere or vacuum The air in the container 1 creates a vacuum environment atmosphere to complete the m...

Embodiment 2

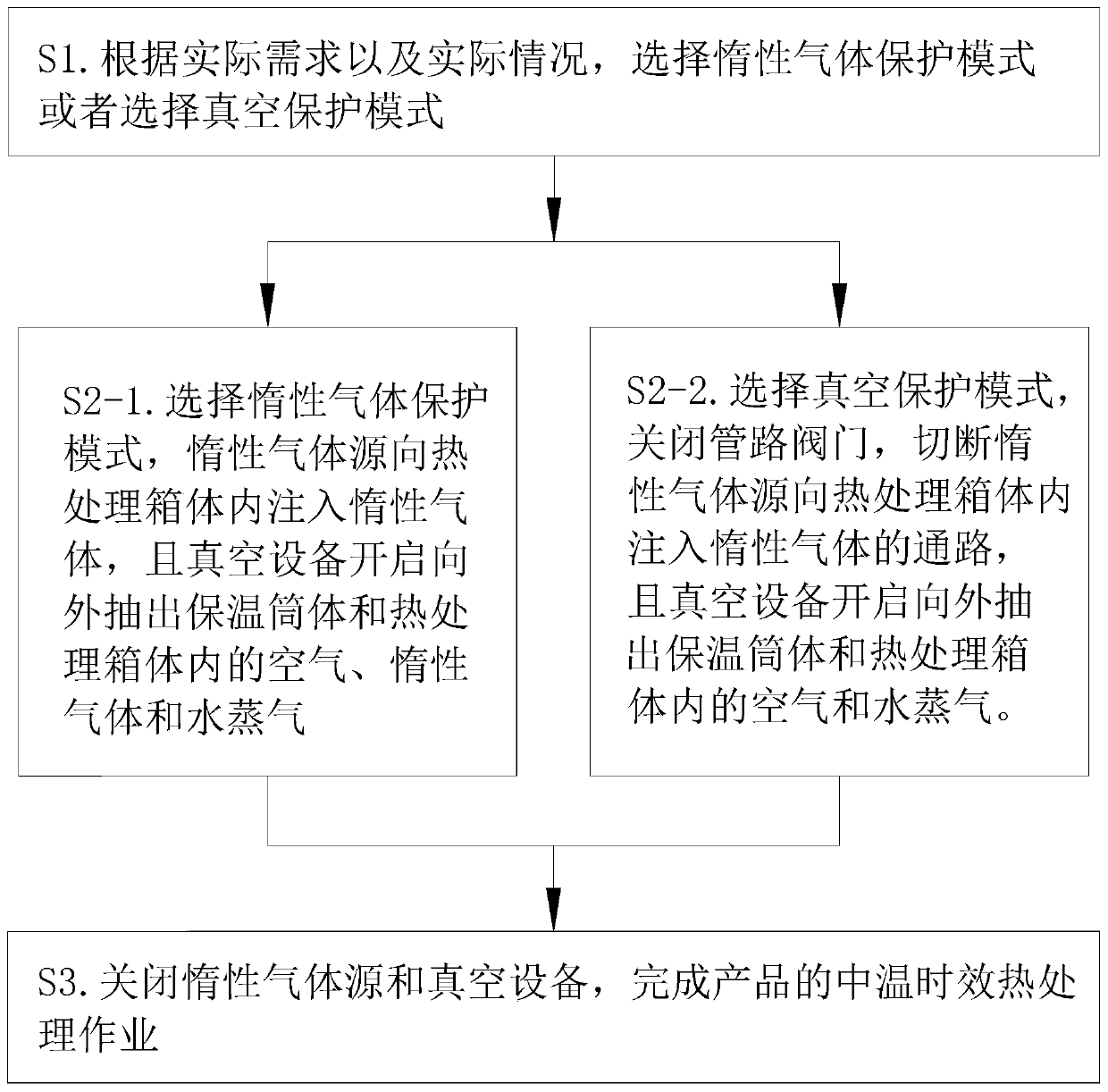

[0041] Such as image 3 As shown, a stainless steel medium-temperature aging heat treatment method, first of all, according to the actual situation, choose to carry out the medium-temperature aging heat treatment in the inert gas protection mode, or choose to carry out the medium-temperature aging heat treatment in the vacuum protection mode. When the inert gas protection mode is selected, the inert gas source 5 injects inert gas into the heat treatment box 3, and the vacuum device 4 is opened to draw out the air, inert gas and water vapor in the insulation cylinder 2 and the heat treatment box 3; Vacuum protection mode, close the pipeline valve 71 to cut off the passage of the inert gas source 5 injecting inert gas into the heat treatment box 3, and open the vacuum device 4 to draw out the air and water vapor in the heat preservation cylinder 2 and the heat treatment box 3 .

[0042] The present embodiment will be further elaborated below in conjunction with specific modes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com