Oil make-up device of pressure compensation hydraulic damper

A technology of hydraulic damper and oil replenishment device, which is applied in valve device, shock absorber, shock absorber, etc., can solve the problems of short service life of seals and unsatisfactory sealing performance for the use environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

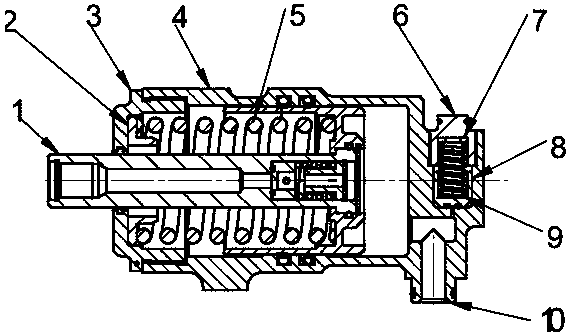

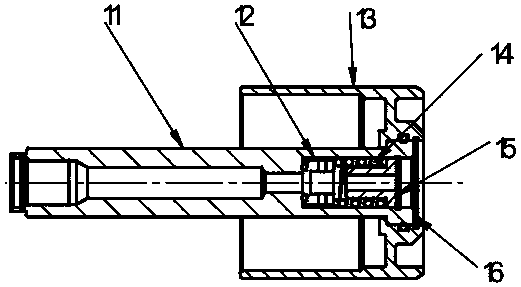

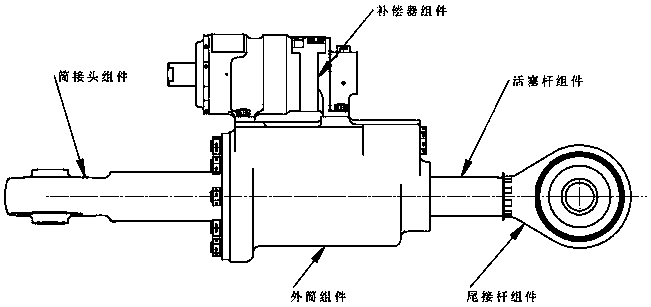

[0016] refer to Figure 1 ~ Figure 3 . In the embodiment described below, an oil replenishing device for a pressure-compensated hydraulic damper includes: an oil cylinder that can be fixed on the cylinder body of the hydraulic damper and a damping nozzle connected to the hydraulic damper on the oil cylinder; Compensation piston 1 in cylinder 4. A thermal safety valve 8 with a radial vertical axis and connected to the oil chamber is provided outside the blind hole end of the oil chamber cylinder 4. The thermal safety valve 8 has a built-in thermal safety valve spring 9, and the seal is vulcanized on the skeleton to realize a soft rubber seal. ;Compensation piston 1 and two "Type II combined seals" are set on the sealing surface of the oil supply box, and the damping spring 5 is set through the built-in bearing 2 of the end cover 3, and the reciprocating motion in the oil chamber cylinder 4 provides the required hydraulic damper. Pressure compensation; a thermal safety valve 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com