Fabric-based capacitive sensor and manufacturing method thereof

A technology of a capacitive sensor and a manufacturing method, which is applied in the direction of converting the output of the sensor and transmitting the sensing components and instruments by means of an electromagnetic/magnetic device, can solve the problems of complex manufacturing process, high cost, poor flexibility, etc., and achieves low cost, Real-time monitoring and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

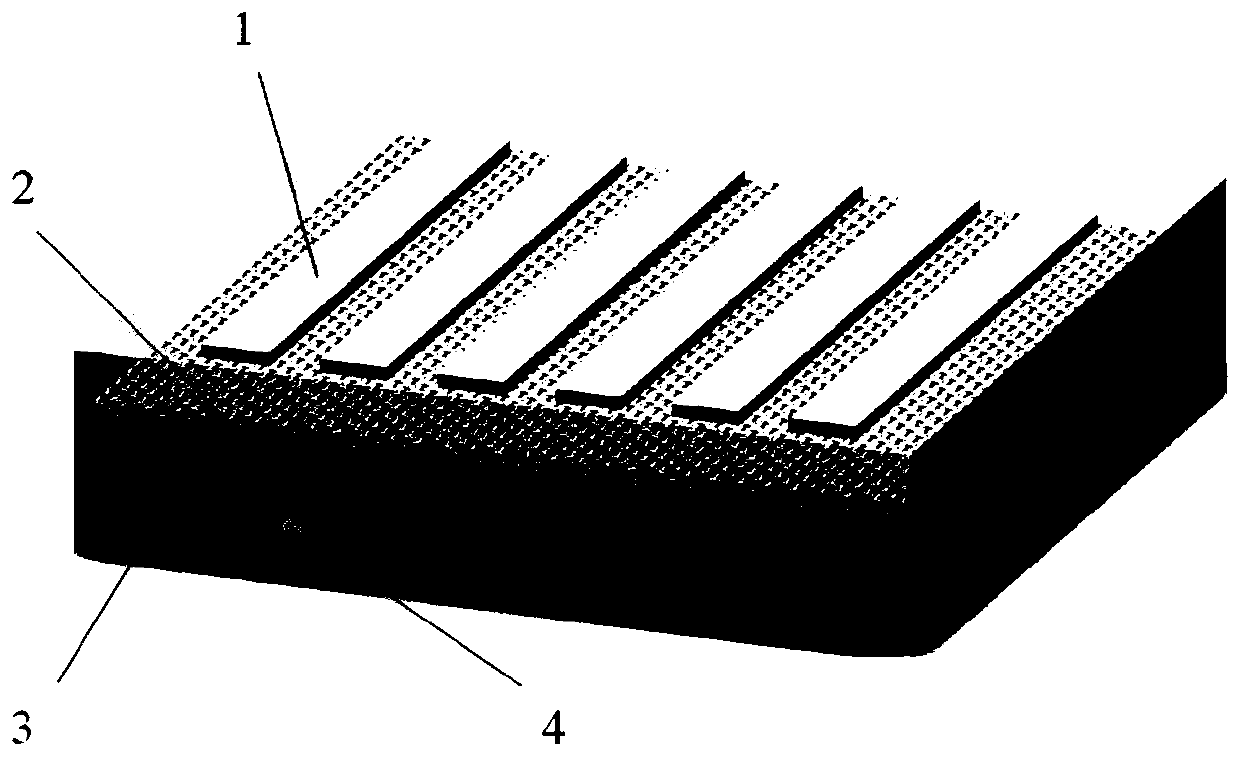

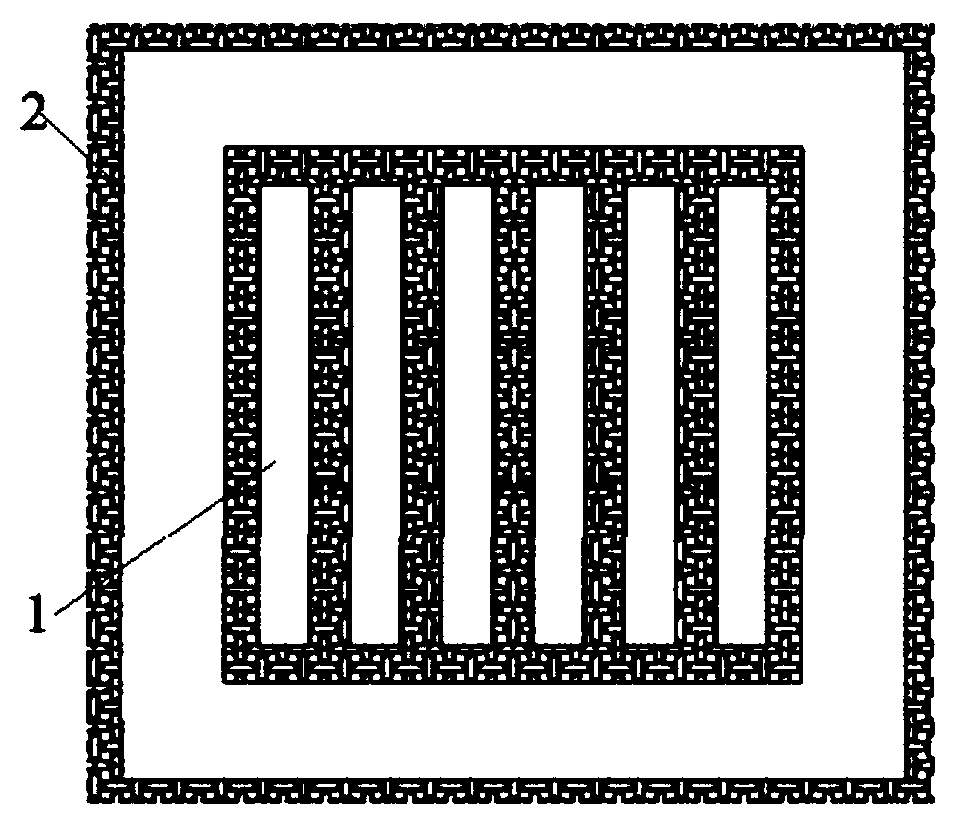

[0054] Step 1. Select the plain weave fabric, cut it into a size of 70mm×70mm, soak the plain weave fabric in alcohol with a volume fraction of 75% for 10 minutes, and ultrasonic power is 80W; take out the plain weave fabric after ultrasonic cleaning with deionized water, and then statically air dry;

[0055] Step 2. Immerse the dried plain weave fabric in the graphene dispersion, then ultrasonic the above plain weave fabric for 20min, the ultrasonic power is 40W, leave it to air dry, and iron the air dried plain weave fabric with an iron;

[0056] Wherein, the dispersion is composed of graphene, polyvinylpyrrolidone and deionized water mixed with a mass ratio of 0.01:0.2:100, wherein the solid content of graphene in the dispersion is 0.01wt%;

[0057] Step 3. Paste conductive copper foil on the upper and lower surfaces of the ironed plain fabric. The length of the conductive copper foil is 40mm, the width is 3mm, and the thickness is 30μm. The conductive copper foil is far aw...

Embodiment 2

[0063] The manufacturing method of this capacitive sensor based on fabric is the same as embodiment 1, the difference is:

[0064] The fabric dielectric layer 2 is a twill fabric;

[0065] In step 1, the time of ultrasonic treatment is 15min, and the power is 80W;

[0066] In step 2, the time of ultrasonic treatment is 25min, and the power is 50W;

[0067] The dispersion is composed of carbon nanotubes, polyvinylpyrrolidone and deionized water mixed with a mass ratio of 0.03:0.7:100, and the solid content of carbon nanotubes in the dispersion is 0.03wt%;

[0068] The length of the conductive copper foil is 45mm and the width is 4mm;

[0069] In step 5, the mass ratio of polydimethylsiloxane and Dow Corning 184 silicone rubber is 5:1;

[0070] In step 6, the curing time is 90 minutes, and the temperature is 70°C.

Embodiment 3

[0072] The manufacturing method of this capacitive sensor based on fabric is the same as embodiment 1, the difference is:

[0073] The fabric dielectric layer 2 is a satin weave fabric;

[0074] In step 1, the time of ultrasonic treatment is 20min, and the power is 70W;

[0075] In step 2, the time of ultrasonic treatment is 30min, and the power is 60W;

[0076] The dispersion liquid is composed of conductive carbon black, polyvinylpyrrolidone and deionized water in a mass ratio of 0.05:1.25:100, and the solid content of the conductive carbon black in the dispersion liquid is 0.05wt%;

[0077] The length of the conductive copper foil is 50mm and the width is 5mm;

[0078] In step 5, the mass ratio of polydimethylsiloxane and Dow Corning 184 silicone rubber is 8:1;

[0079] In step 6, the curing time is 105 minutes, and the temperature is 65°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com