Polyethylene microporous film and preparation method and application thereof

A polyethylene microporous film and polyethylene resin technology, applied in the field of microporous film, can solve problems such as extremely poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention comprises the steps:

[0025] 1) Blending polyethylene resin and diluent paraffin oil into a twin-screw extruder, and then rapidly cooling it through a casting roll to make it phase-separated rapidly, and obtaining a thick sheet with a semi-elliptical cross-section, such as Figure 4 shown in (a); rather than thick slices with regular triangular cross-sections, undulating wavy lines, triangular protrusions or triangular depressions, respectively, as shown in Figure 4 (b), (e), (c) and (d) in. The extreme difference in thickness / width of the slab is controlled at 100-300um / 500mm;

[0026] 2) The thick sheet is stretched longitudinally (MDO) by means of gradient increasing speed, and the roll speed ratio of two adjacent stretching rolls is controlled at 1.1-1.2;

[0027] 3) Both sides of the film after longitudinal stretching are fixed with clamps, and the first transverse stretching (TDO1) is carried out, and the stretching ...

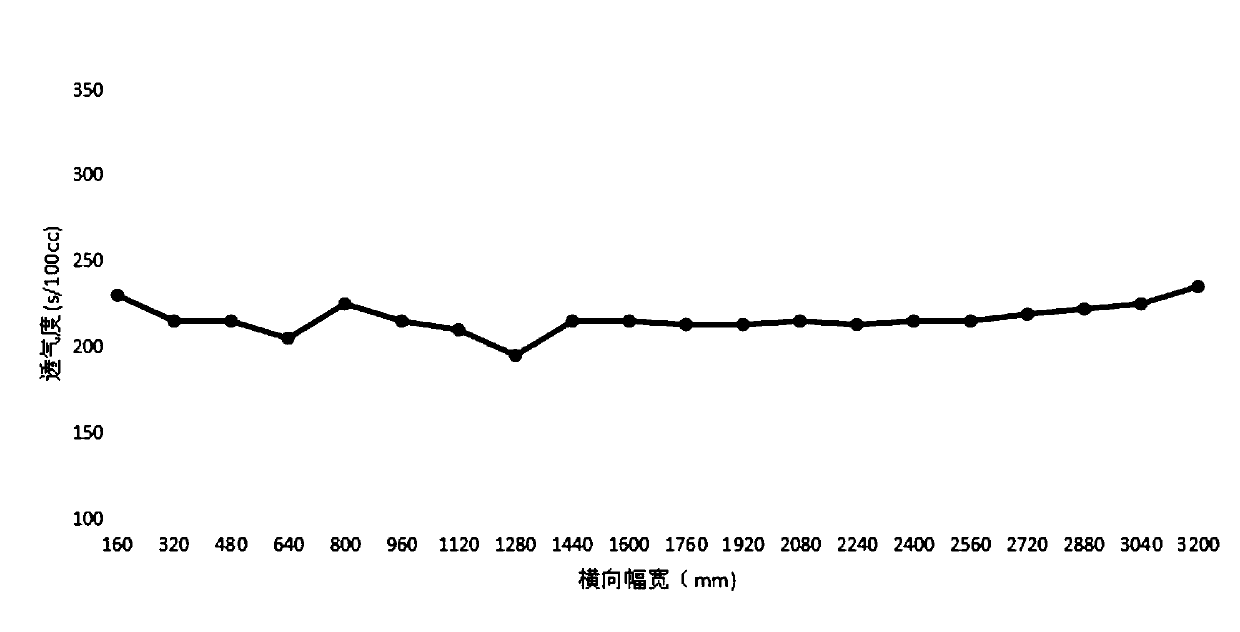

Embodiment 1

[0031] 1) Polyethylene resin and thinner paraffin oil are blended into a twin-screw extruder according to a mass ratio of 28:72, and the average molecular weight of the polyethylene resin is 500,000, and are transported to the extrusion die through a metering pump. The head temperature was set at 200°C. Afterwards, the casting roll is extremely cold to make it phase-separate rapidly, and a thick sheet is obtained. The thickness of the thick sheet is extremely poor / width is controlled at 140um / 500mm;

[0032] 2) The thick sheet is stretched longitudinally (MDO) in a manner of gradient increase in speed, the stretching temperature is 110°C, and the roll speed ratio of two adjacent stretching rolls is controlled at 1.11;

[0033] 3) Then both sides of the film are fixed with clamps, and the first transverse stretching (TDO1) is carried out, the transverse stretching ratio is 7 times, and the stretching temperature is 123°C;

[0034] 4) The obtained microporous oil film is extrac...

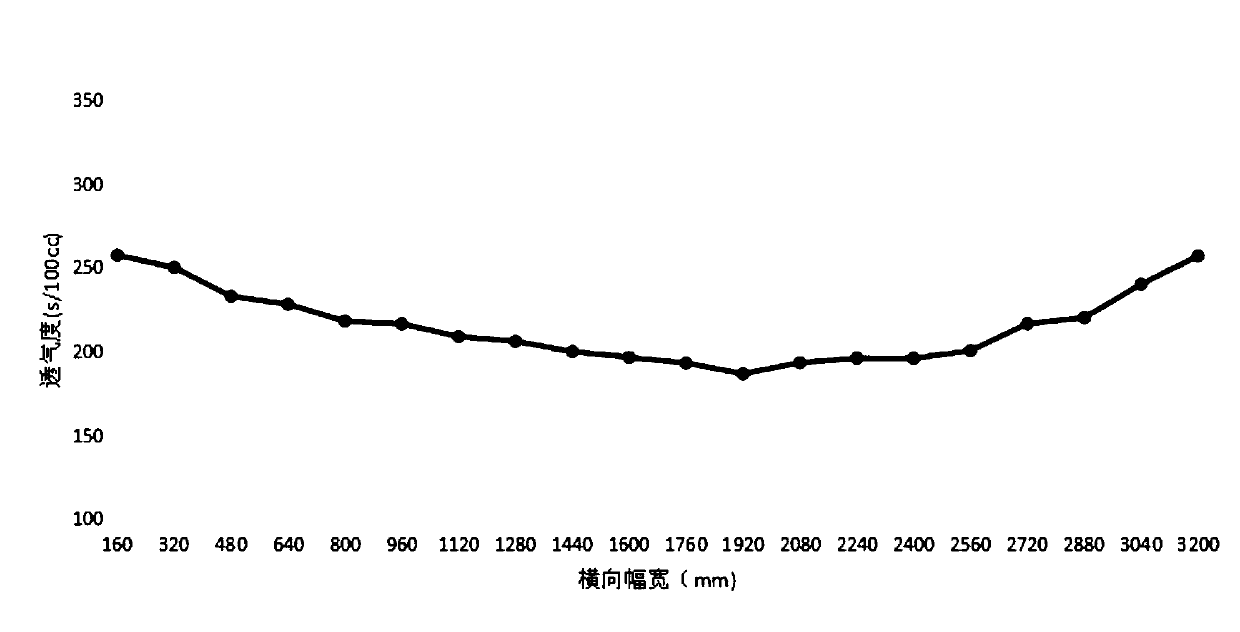

Embodiment 2

[0038] 1) Polyethylene resin and diluent paraffin oil are blended into a twin-screw extruder according to the mass ratio of 30:70, and the average molecular weight of the polyethylene resin is 700,000, and are transported to the extrusion die through a metering pump. The head temperature was set at 200°C. Afterwards, the casting roller is extremely cold to make it phase-separated rapidly, and a thick sheet is obtained, and the thickness of the thick sheet is extremely poor / width is controlled at 130um / 500mm;

[0039] 2) The slab is longitudinally stretched (MDO) in a manner of gradient increasing speed, and the stretching temperature is 120°C. In the longitudinal stretching mode, the roll speed ratio of the stretching roller is 1.13;

[0040] 3) Then both sides of the film are fixed with clamps, and the first transverse stretching (TDO1) is carried out, the transverse stretching ratio is 7.6 times, and the stretching temperature is 122°C;

[0041] 4) The obtained microporous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com