Preparation method of low-cost high-purity carbon nanotube film

A carbon nanotube film, carbon nanotube technology, applied in the direction of carbon nanotubes, single-walled carbon nanotubes, multi-walled carbon nanotubes, etc., can solve the problems of damage to carbon nanotubes, unsafe factors, long time period, etc. Achieve the effect of simple preparation process, innovative technical route and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

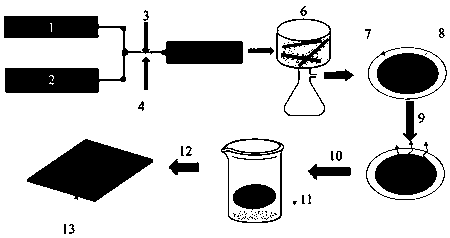

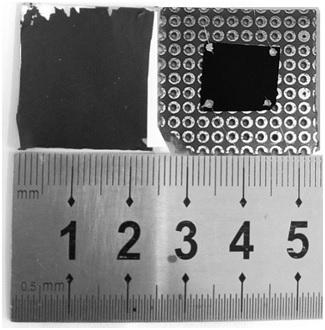

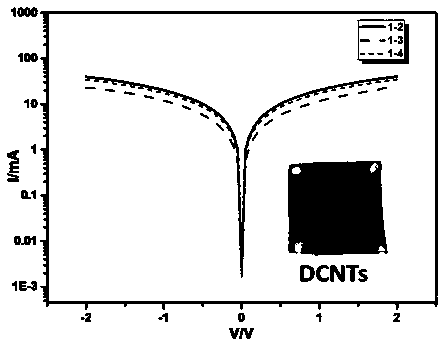

[0025] Example 1, such as Figure 1-4 shown

[0026] Weigh 10 mg of double-walled carbon nanotubes into a beaker, add 100 mL of absolute ethanol, ultrasonicate in a water bath for 36 min, then perform mechanical stirring at a stirring speed of 500 rpm for 2 h, and then ultrasonicate in a water bath after the stirring is completed. After 3 min, a uniform dispersion of carbon nanotubes can be obtained. Vacuum filter the carbon nanotube dispersion immediately to obtain a carbon nanotube film adhered to the filter paper. After drying the nanotube film, make a notch along the edge of the film, put it in absolute ethanol, boil at 75°C for 5-10 minutes, and the carbon nanotube film will be peeled off from the filter paper. The stripped carbon nanotube film is placed in absolute ethanol, and when transferring, the transfer of carbon nanotubes can be realized by picking up the required substrate.

[0027] Such as figure 1 As shown, it is a schematic diagram of the preparation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com