Working head of a multi-blade horizontal weeder and leak-proof weeding method

A weeding machine and working head technology, which is applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of inability to obtain weeding area and low weeding efficiency, achieve increased weeding area, simple structure, and prevent missed mowing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the technical means, creative features, objectives and technical effects realized by the present invention easy to understand, the present invention will be further elaborated below through specific implementation methods in conjunction with the accompanying drawings.

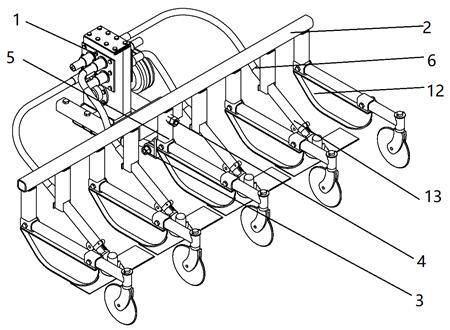

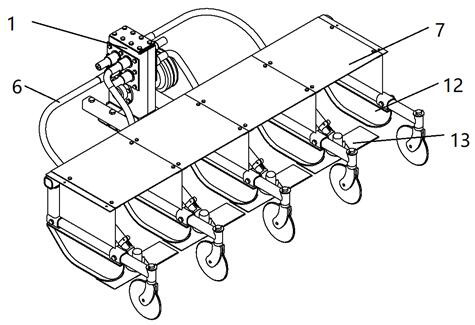

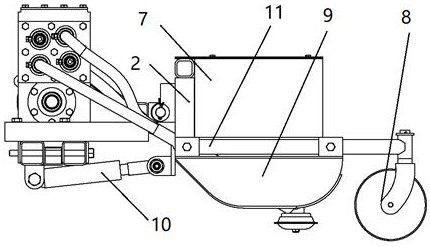

[0066] Such as figure 1 , figure 2 Shown a kind of multi-blade horizontal weeder working head, comprises frame 5, and described frame 5 comprises crossbeam 2, is provided with several weeding mechanisms 13 on described crossbeam 2, and described weeding mechanism 13 and described crossbeam 2 is fixedly connected, and one side and / or both sides of each weeding mechanism 13 also includes a guide weeding mechanism 12, and the guide weeding mechanism 12 is fixedly connected with the beam 2. In this embodiment, each weeding mechanism 13 is independently connected to the power output shaft end of the speed-up gearbox 1 of the machine body through the transmission flexible shaft 6, and the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com