Atomization cooling equipment for grape greenhouse

A grape and equipment technology, applied in the field of agricultural equipment, can solve the problems of low degree of intelligence, poor fertilization during flowering period, and unfulfilled seasons, and achieves unique shape design, increased placement firmness and stability, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

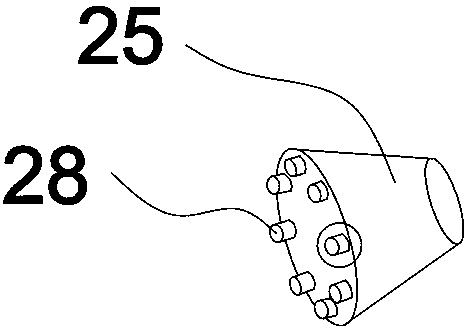

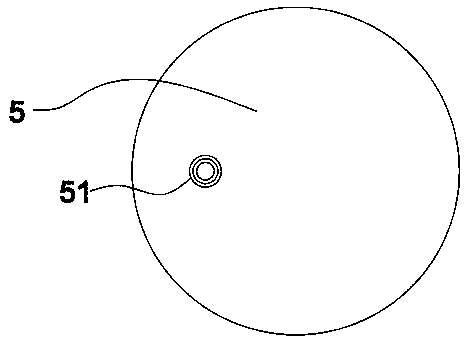

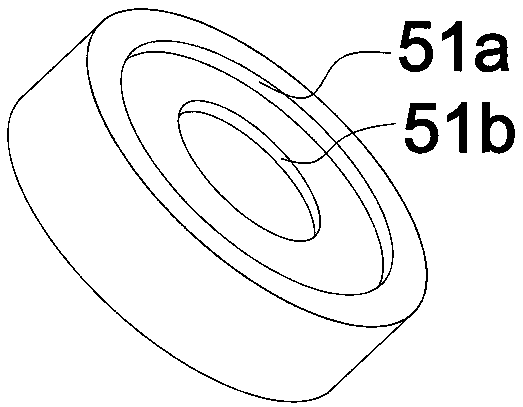

[0024] Such as Figure 1-7 As shown, the atomization and cooling equipment for grape greenhouses includes a water bucket 7, a bottom plate 33 is provided under the water bucket 7, and a universal wheel 32 is movably connected under the bottom plate 33. , the motor 3 is provided with a motor switch 1, the motor 3 is provided with a plate body 4, the plate body 4 is placed above the bucket 7, the output end of the motor 3 is connected to the first water suction pipe 8, and the middle section of the first water suction pipe 8 is connected to the second The water suction pipe 24 and the second water suction pipe 24 pass through the dividing plate 23, the dividing plate 23 separates the buckets 7, and one side of the dividing plate 23 is embedded with a cooling pipe 31. The device has strong mobility, large movable range, and good load-bearing capacity. The motor switch can control the first water suction pipe and the second water suction pipe. The partition divides the bucket into...

Embodiment 2

[0033] Such as Figure 1-7 As shown, the atomization cooling equipment for grape greenhouses works as follows: pull the device into the greenhouse and place it in a suitable position to turn on the motor 3, and the switches on the motor 3 respectively control the first water suction pipe 8 and the second water suction pipe 24, and the second water suction pipe 8 A water suction pipe 8 extracts the water in the bucket 7, sprays it into the greenhouse by the atomizing nozzle 28, and is used for cooling in the greenhouse. The second water suction pipe 24 is used for watering the greenhouse. When the water level in the bucket 7 drops, the floating ball 10 drops simultaneously. Driven by the floating ball 10, the upper nut 22 on the upper end of the rod shaft 11 pulls the pressure rod 21 to descend. At this time, the pressure rod 21 triggers the water supply switch 19 to start, the water supply switch 19 turns on the power, and the solenoid valve 13 starts to add water to the bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com