Greenhouse fungus mushroom automatic watering equipment

A technology for automatically adding water and mushrooms, applied in the fields of botanical equipment and methods, mushroom cultivation, gardening, etc., can solve the problems of waterless operation of the motor and the quality of imaging mushrooms, so as to overcome the idling of the motor, facilitate the operation, and reduce the inspection labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

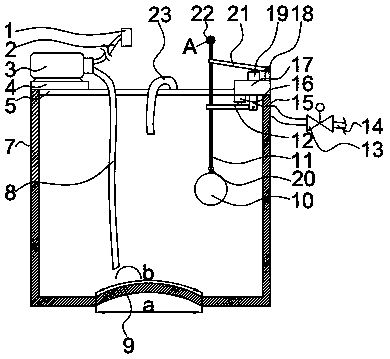

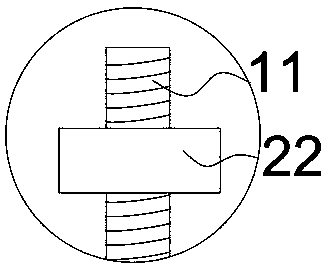

[0024] refer to Figure 1 to Figure 4, automatic watering equipment for greenhouse mushrooms, comprising bucket 7, a humidifying device positioned at one end of the bucket 7 top and a water level regulating device positioned at the other end of the bucket 7 top, the top of the bucket 7 is provided with a bung 5, and the water inlet of the suction pipe 8 of the humidifying device Located in the bucket 7, the water level regulating device includes a float 10 and a mounting plate 17, the mounting plate 17 is located at one end of the bung 5, the upper middle part of the mounting plate 17 is provided with a water supply switch 19, and the outside of the water supply switch 19 is provided with a pole 18, The water-adding switch 19 is provided with the depression bar 21 that is hinged with the pole 18, the lower end of the mounting plate 17 is provided with a water stop switch 16, the outside of the water stop switch 16 is provided with a mount 15, and the water stop switch 16 is hor...

Embodiment 2

[0032] The working principle of the automatic water adding equipment for mushrooms in the greenhouse of the present invention is as follows: the automatic water adding equipment is placed in a suitable position in the mushroom greenhouse, the motor 3 is turned on, the water suction pipe 8 extracts the water in the bucket 7, and is sprayed into the greenhouse by the atomizer 1 , when the water level in the bucket 7 drops, the floating ball 10 will drop synchronously. Driven by the floating ball 10, the upper nut 22 on the upper end of the threaded rod 11 will pull the pressure rod 21 to drop. 19 Turn on the power, start the solenoid valve 13 to add water to the bucket 7, the floating ball 10 moves up with the rise of the water level, moves up to the lower nut 20 to withstand the lower part of the ejector rod 12, and synchronously drives the water stop switch 16 to start, and closes the solenoid valve 13. The purpose of automatic water addition without supervision has been realiz...

Embodiment 3

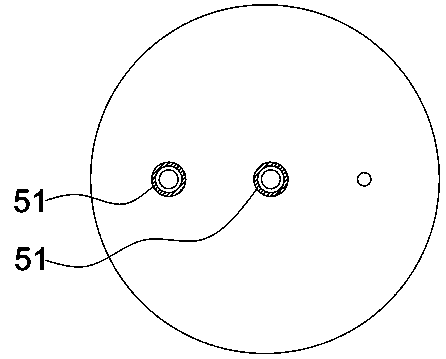

[0034] refer to Figure 5 to Figure 6 , the optimization scheme of this embodiment on the basis of Embodiment 1 is: the bottom of the bucket 7 is provided with a filter plate 6 near the bottom 9 of the convex arc. The filter plate 6 can filter out impurities in the water to prevent impurities from entering the water suction pipe 8, thereby blocking the nozzle of the atomizer 1 and affecting the operation of the humidifying device. At the same time, the filter plate 6 can buffer the impact force of the water discharge pipe 23 on the bottom of the bucket 7, To maintain the stability and durability of the bucket 7 and improve the service life of the automatic water-adding equipment, preferably, the grids in the filter plate 6 can be filled with physical adsorbents such as activated carbon, activated alumina, molecular sieves and the like.

[0035] The conventional techniques in the foregoing embodiments 1-3 are prior art known to those skilled in the art, and will not be describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com