Chocolate quantitative pouring device

A quantitative pouring and chocolate technology, applied in the fields of cocoa, food science, application, etc., can solve the problems of uneven distribution of chocolate pouring, affecting the production efficiency of enterprises, affecting the surface appearance of products, etc., to achieve more practicability and improve production efficiency of enterprises , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

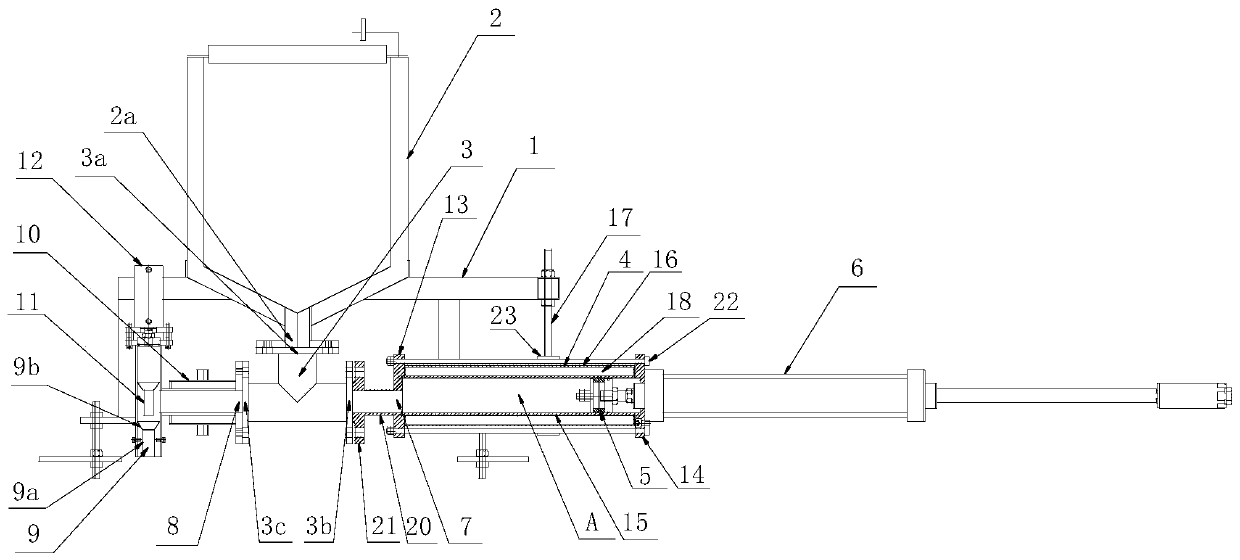

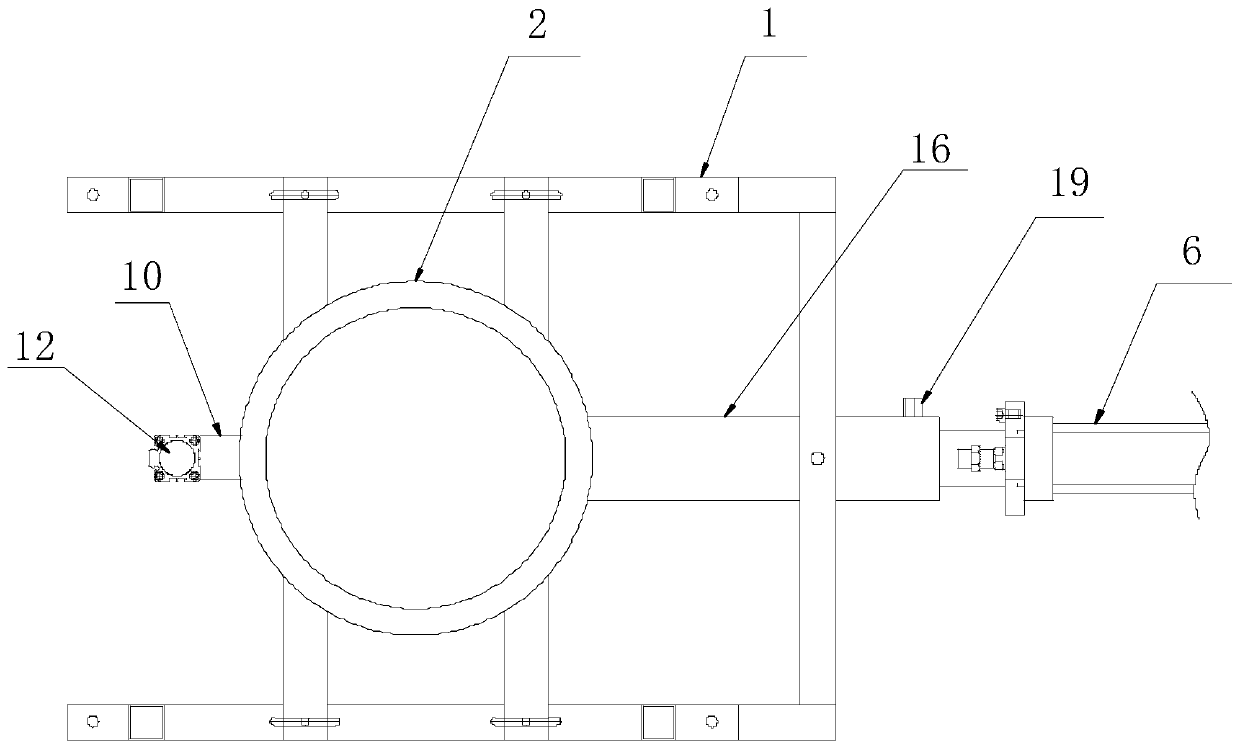

[0033] Embodiment: combine below Figure 1~2 As shown, the specific implementation of this chocolate quantitative pouring device provided by the invention is described in detail as follows:

[0034] This chocolate quantitative pouring device is used to complete the quantitative pouring of 1kg of chocolate at one time, and its whole is composed of a fixed bracket 1, a material cylinder 2, a T-shaped three-way valve 3, a quantitative extraction mechanism and a discharge cut-off mechanism. Wherein the material cylinder 2 is fixed on the fixed support 1, and the bottom of the material cylinder 2 is provided with a blanking opening 2a. The T-shaped three-way valve 3 is arranged below the material cylinder 2, and is provided with a feed valve port 3a on the top, a first discharge valve port 3b and a second discharge valve port 3c on the left and right sides. Wherein, the feed valve port 3a is connected with the blanking port 2a of the material cylinder 2 .

[0035] The quantitativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com