Rotational alternative ultrasonic defoaming device

A rotating interlaced and ultrasonic technology, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reducing the defoaming effect, reducing the defoaming efficiency, and poor filtration effect, so as to improve the defoaming accuracy and improve the Defoaming effect, increasing the effect of liquid turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

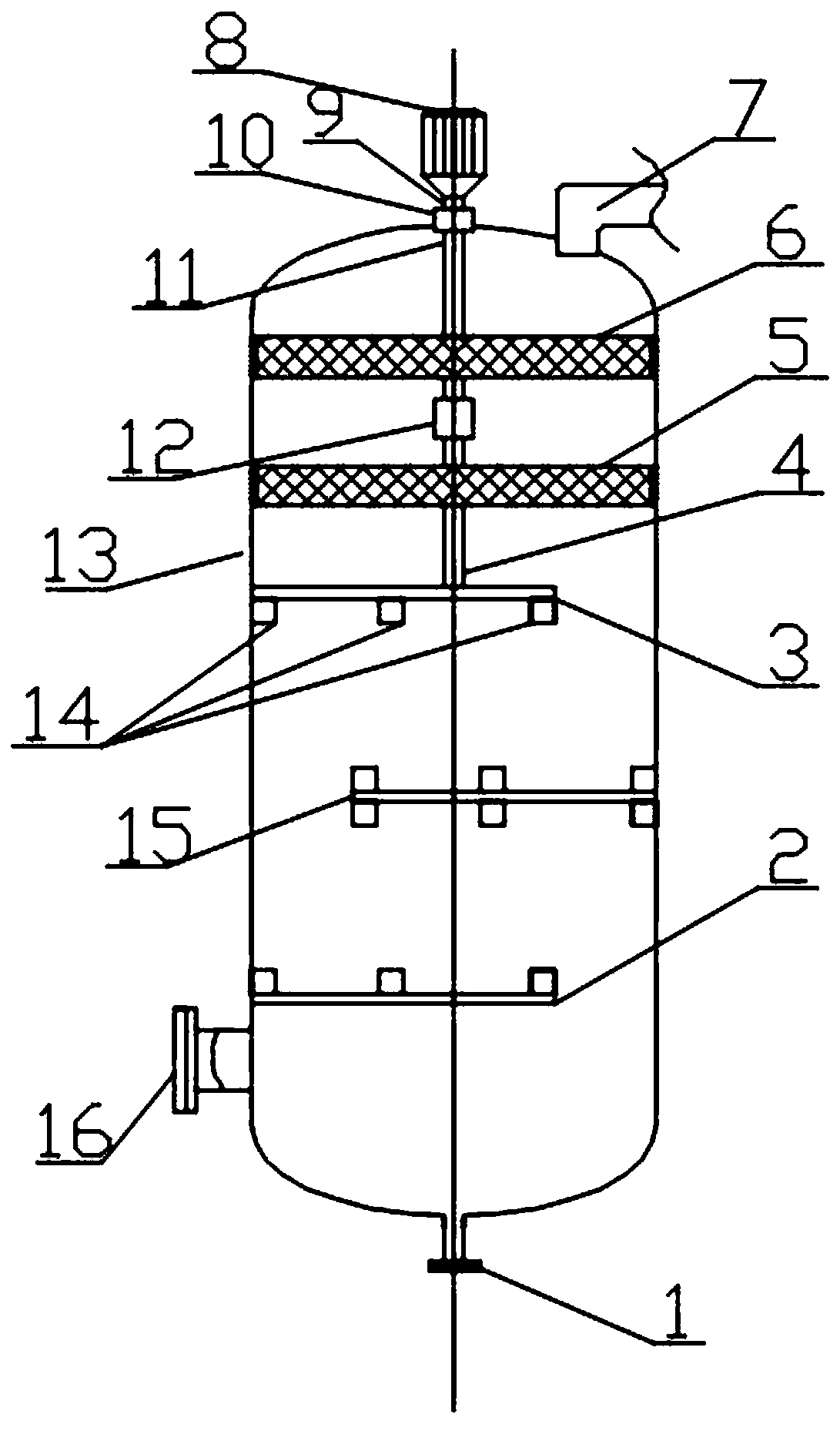

[0025] A rotary staggered ultrasonic defoaming device includes a casing 13. Its innovation lies in: a feed inlet 16 is provided on the lower side of the casing, a liquid outlet 1 is provided at the bottom of the casing, and a liquid outlet 1 is provided on the bottom of the casing. A steam outlet 7 is provided, a motor 8 is fixedly installed on the top of the shell, a first drive shaft 11 and a second drive shaft 4 are sleeved on the motor output shaft 9 through a sleeve 10, and the first baffle is arranged in the shell from bottom to top. Plate 2, second baffle 15, third baffle 3, first demister 5 and second demister 6, first baffle, second baffle and third baffle are staggered left and right It is arranged on the inner wall of the shell, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com