Abrasive jet system for cutting downhole casing and method of use thereof

An abrasive jet and cutting well technology, which is applied in abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problems of inability to segment milling, inability to guarantee continuous work, and high abrasive water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

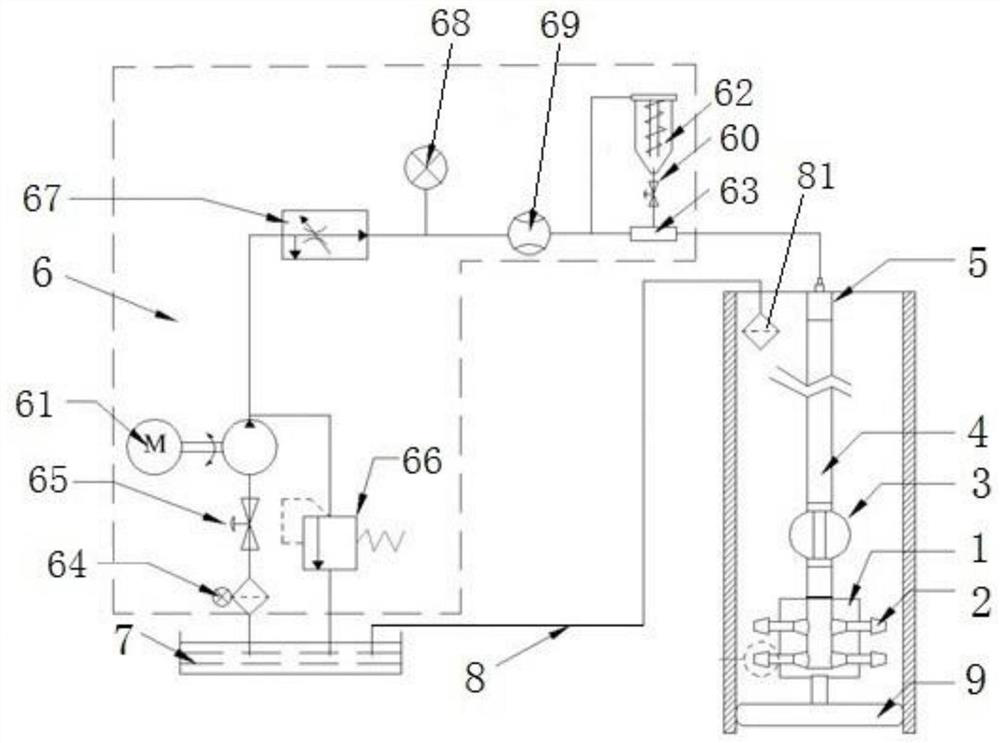

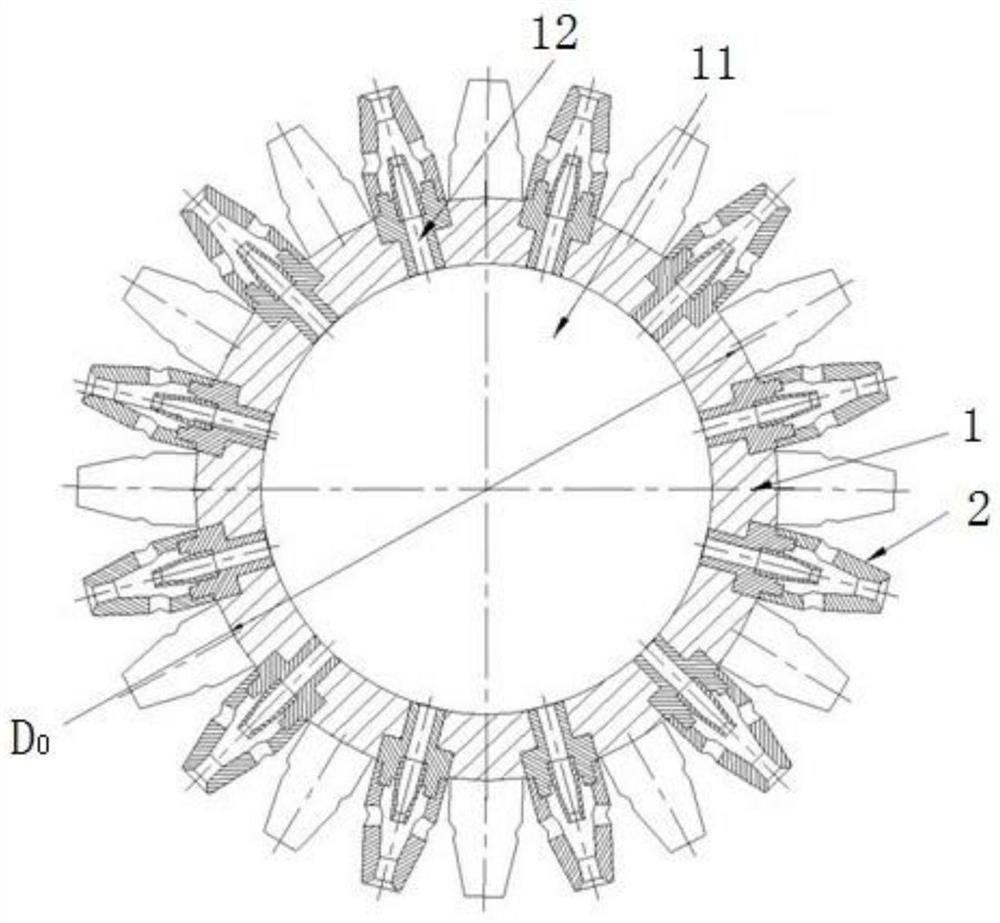

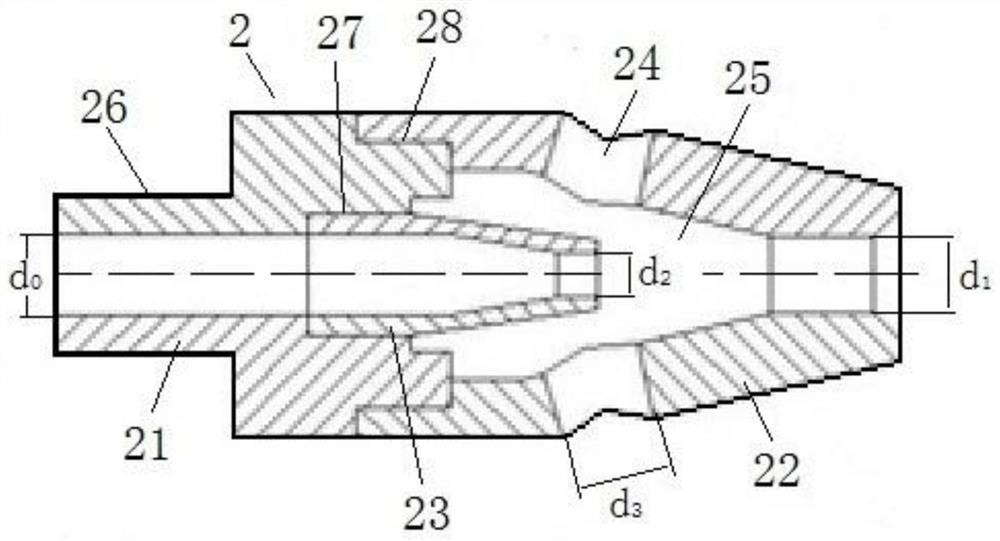

[0028] see Figure 1 to Figure 6 , the abrasive jet system for cutting downhole casings shown includes a water tank 7, an abrasive jet generating device 6, an oil pipe 4, a downhole centralizer 3 and a spray gun 1 connected in sequence, and the end of the spray gun 1 is provided with a downhole centralizer 3 Axial blind holes 11 connected by water channels, on multiple radial planes of the spray gun 1, a plurality of nozzle holes 12 communicating with the axial blind holes 11 are arranged radially, and the nozzles on adjacent radial surfaces The holes 12 are arranged alternately, and each nozzle hole 12 is provided with a nozzle 2 . The nozzle 2 includes a coaxially arranged base 21, an outer nozzle 22 and an inner nozzle 23, the base 21 is provided with an axial through hole, one end is provided with a first external thread 26 connected to the nozzle hole 12, and the other end is connected to the outer The nozzle 22 and the inner nozzle 23, the inlet end of the outer nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com