Sludge drying system and drying method for multi-stage heat energy step utilization

A sludge drying, multi-stage technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of poor system operation stability, easy blockage of exhaust steam regenerator, and low cycle efficiency, so as to reduce energy consumption Loss, improve cycle thermal efficiency, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

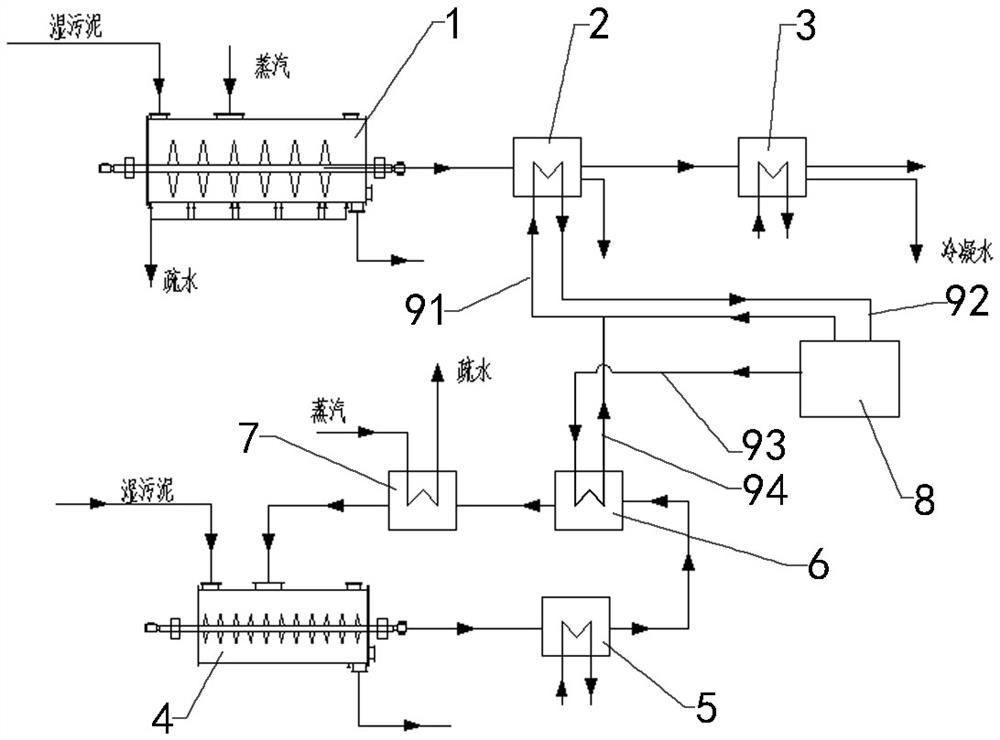

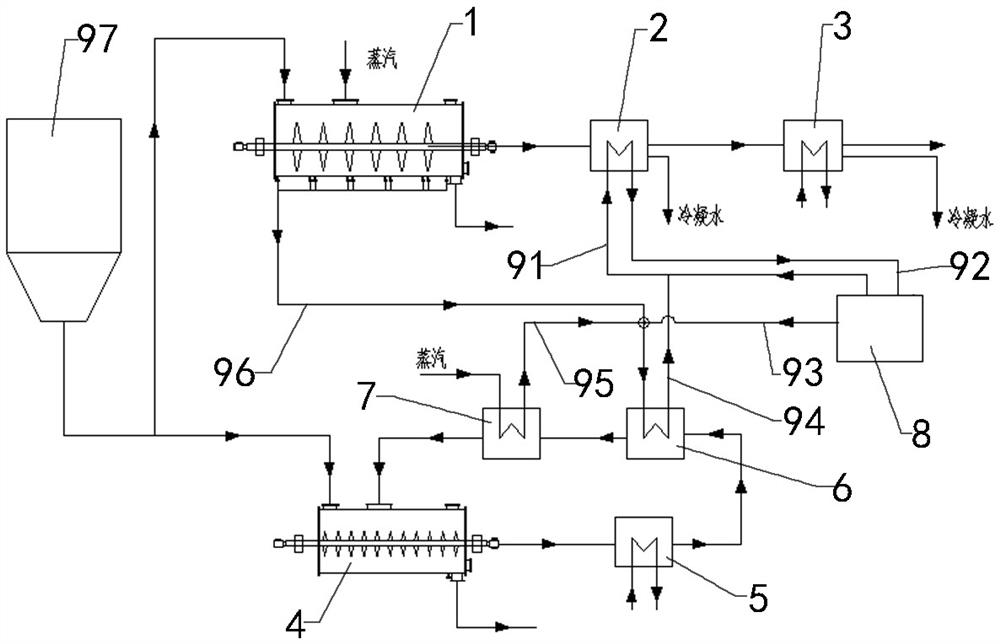

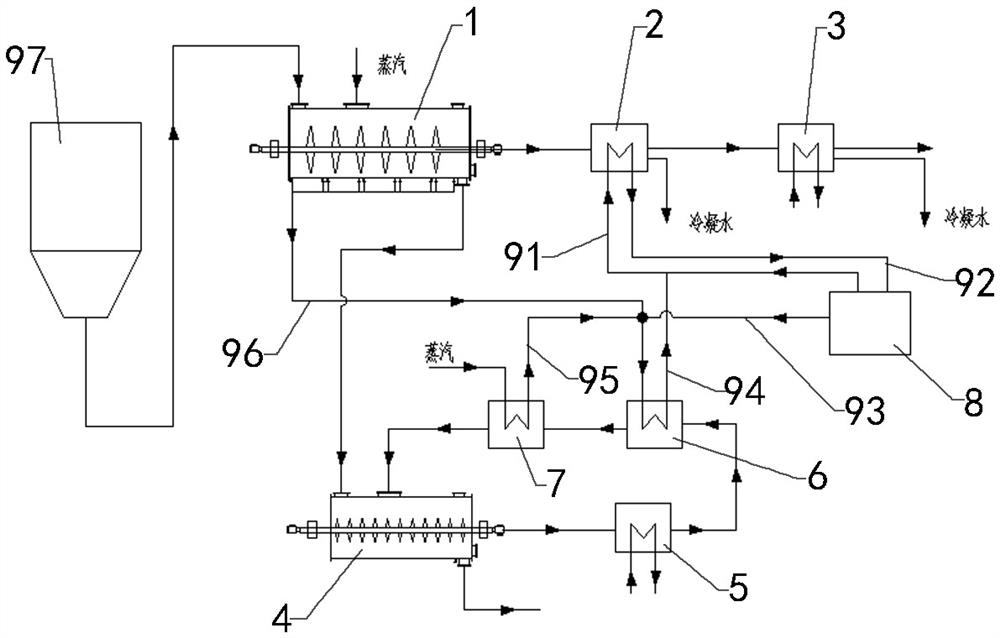

[0041] Such as figure 1 As shown, the sludge drying system for multi-stage thermal energy cascade utilization of the present invention includes a steam drying system, a hot air drying system, and a circulating heat exchange system connecting the steam drying system and the hot air drying system.

[0042] The steam drying system includes at least one steam drying machine, exhaust steam regenerator 2 and exhaust steam condenser 3. The feed port of the steam drying machine 1 is connected to the wet sludge storage bin 97, and the steam outlet is sequentially passed through pipelines. Connected in series with the exhaust steam regenerator 2 and the exhaust steam condenser 3, the steam dryer 1 used in this embodiment is a rotary disc non-contact dryer.

[0043] The steam outlet of the steam dryer 1 is connected to the steam inlet of the exhaust steam regenerator 2, and a large amount of high-temperature steam containing impurities evaporated from the wet sludge is cooled by heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com