U-shaped algae recovery purification device for coupling algae removal

A purification device, U-shaped technology, applied in chemical instruments and methods, special treatment targets, water/sewage treatment, etc., can solve problems such as secondary pollution, inability to recycle algae, etc., to prevent excessive blockage and realize waste utilization , the effect of protecting the water environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

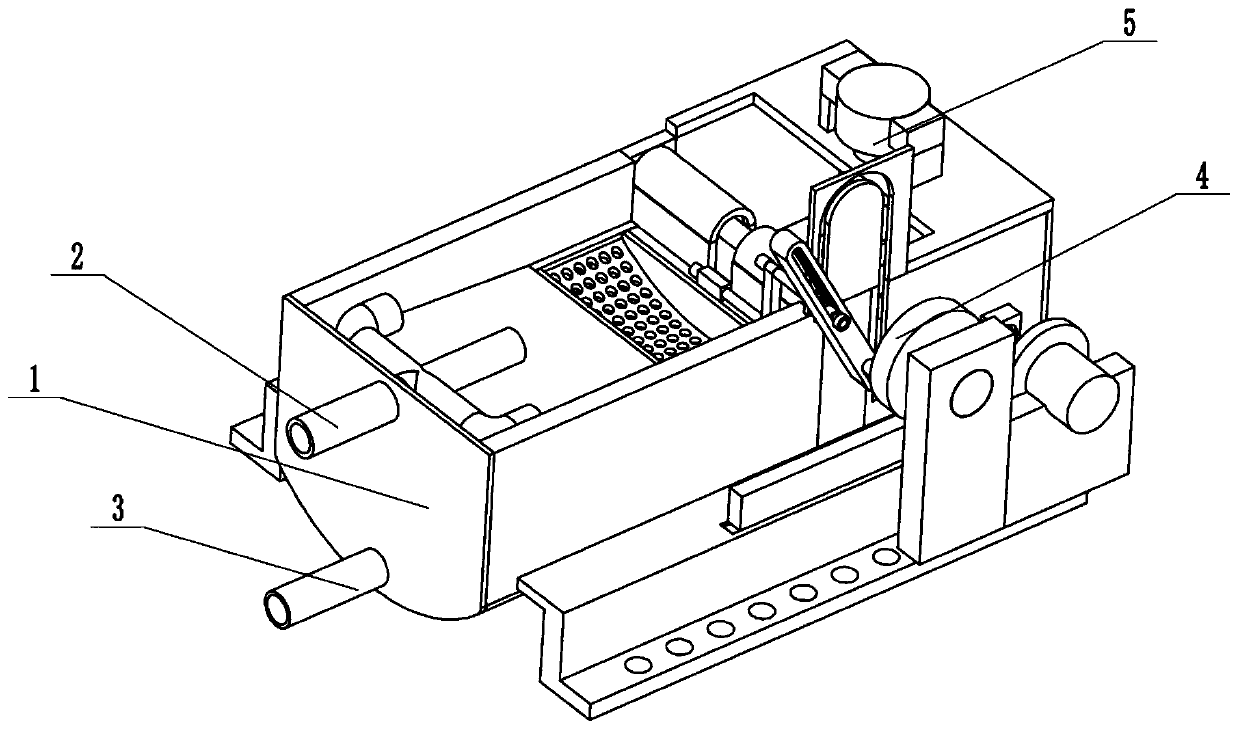

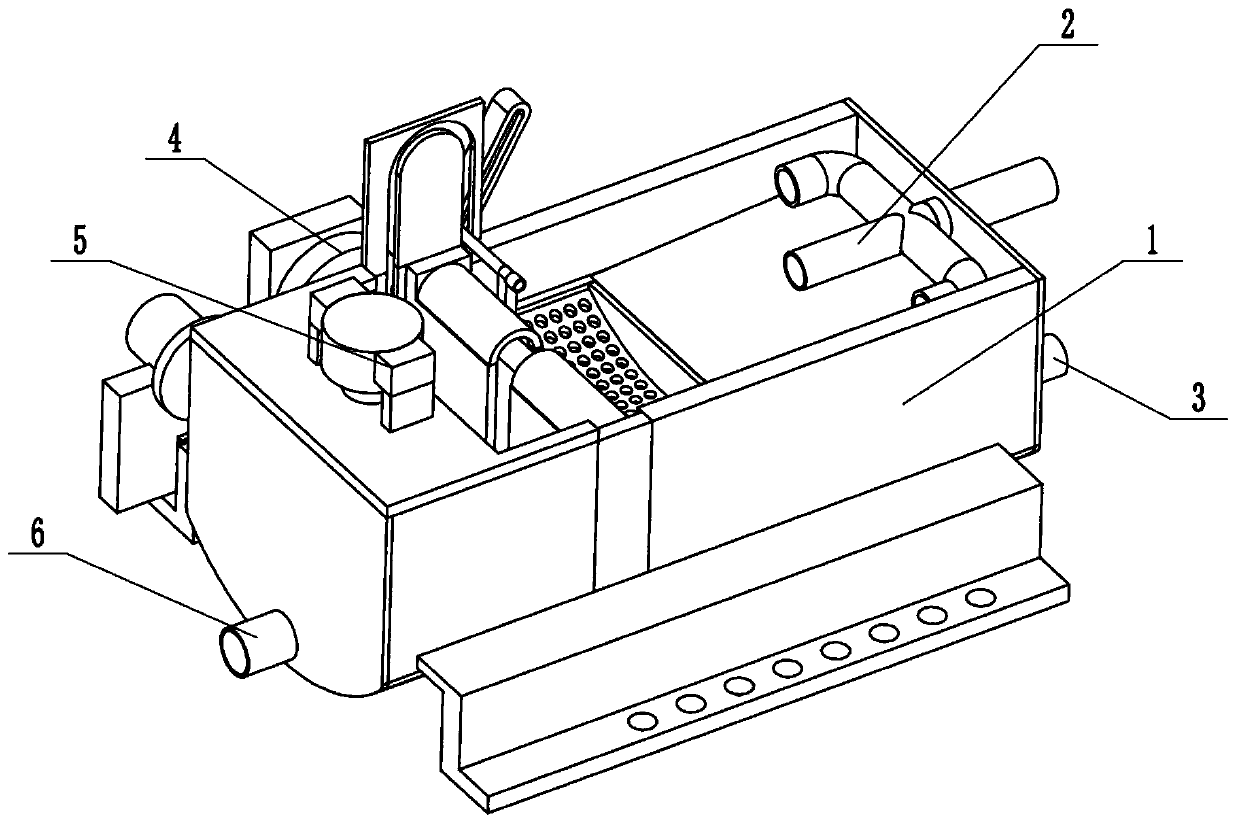

[0028] Such as Figure 1 to Figure 8 As shown, a U-shaped algae recovery and purification device coupled with algae removal includes a U-shaped fixed cylinder 1, a split feed pipe 2, a waste water discharge pipe 3, an algae collection pusher 4, an algae mud crushing agitator 5, and a valved The algae mud recovery pipe 6, the split feed pipe 2 is fixedly connected to the upper side of the rear end of the U-shaped fixed cylinder body 1, and the waste water discharge pipe 3 is fixedly connected to the lower side of the rear end of the U-shaped fixed cylinder body 1. The algae mud recovery pipe 6 is fixedly connected to the lower side of the front end of the U-shaped fixed cylinder body 1. The algae mud recovery pipe 6 with valves, the split feed pipe 2 and the waste water discharge pipe 3 are all connected to the inside of the U-shaped fixed cylinder body 1, and algae are collected. The right end of the pusher 4 is fixedly connected to the U-shaped fixed cylinder 1, the algae col...

specific Embodiment approach 2

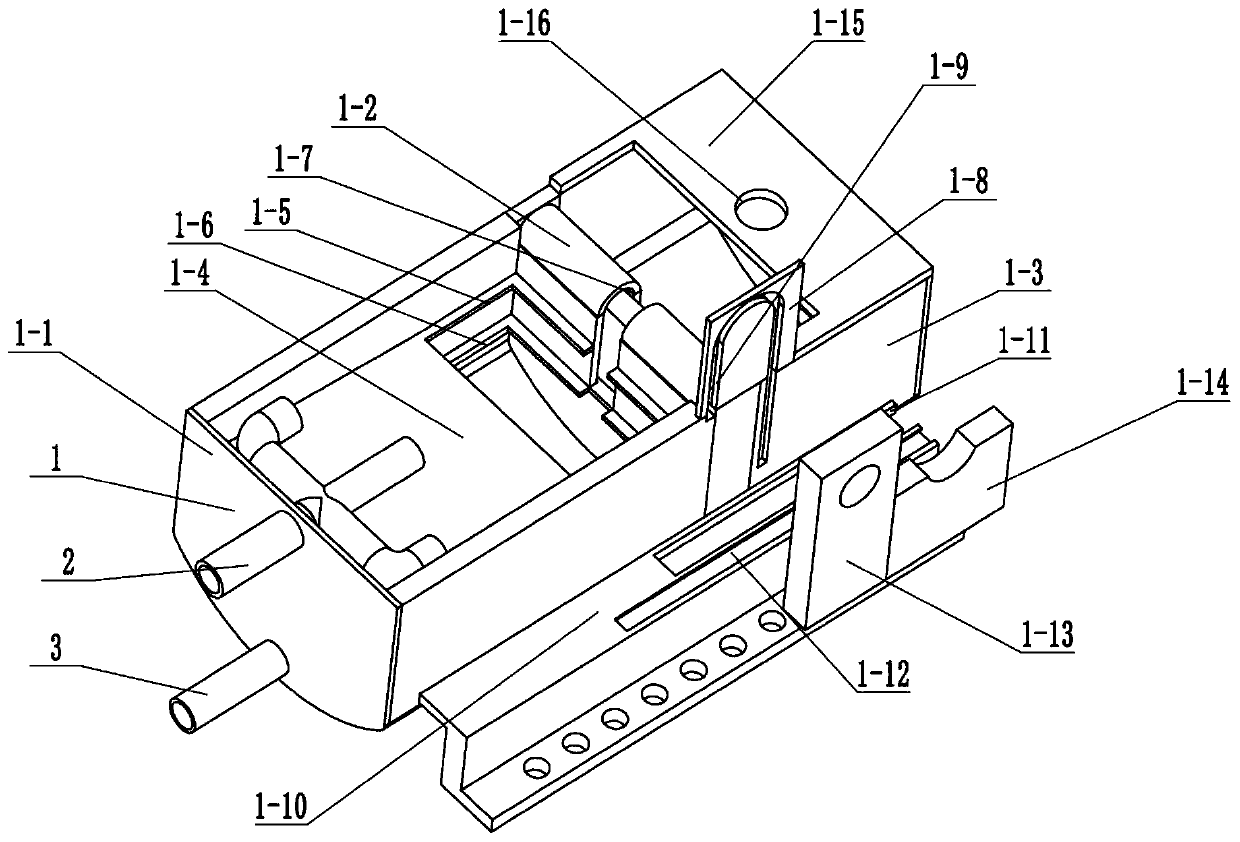

[0030] Such as Figure 1 to Figure 8 As shown, this embodiment will further explain Embodiment 1. The U-shaped fixed cylinder 1 includes a separation cylinder 1-1, a T-shaped sliding seat 1-2, a stirring and crushing cylinder 1-3, and a layer of isolation filter Board 1-4, 1st floor rectangular channel 1-5, 2nd floor rectangular channel 1-6, U-shaped T-shaped chute 1-7, extension plate 1-8, U-shaped track chute 1-9, right Z Z-shaped fixed bottom plate 1-10, left Z-shaped fixed bottom plate 1-17 and two-layer isolation filter plate 1-18, the front end of the described separation cylinder 1-1 is fixedly connected with T-shaped sliding seat 1-2, and the T-shaped sliding seat The front end of 1-2 is fixedly connected to the mixing and crushing cylinder 1-3, the first layer of isolation filter plate 1-4 and the second layer of isolation filter plate 1-18 are uniformly fixedly connected in the separation cylinder 1-1 from top to bottom, and the first layer of isolation filter plate ...

specific Embodiment approach 3

[0032] Such as Figure 1 to Figure 8 As shown, this embodiment further explains the second embodiment. The U-shaped fixed cylinder 1 also includes an anti-blocking slot 1-11, a rack T-shaped chute 1-12, a fixed shaft seat 1-13, Motor fixing seat 1-14, upper baffle plate 1-15, center turning hole 1-16, two water flow ramps 1-19 and blue algae ramps 1-20, and the anti-blocking slot 1-11 is set up and down On the right Z-shaped fixed base plate 1-10, the rack T-shaped chute 1-12 is arranged on the front end of the right Z-shaped fixed base plate 1-10, and the fixed shaft seat 1-13 is fixedly connected to the right Z-shaped fixed base plate 1-10 The upper end of the motor holder 1-14 is fixedly connected to the front end of the fixed shaft seat 1-13 and the upper end of the right Z-shaped fixed bottom plate 1-10, and the upper baffle plate 1-15 is fixedly connected to the upper end of the mixing and crushing cylinder 1-3 , the central turning hole 1-16 runs through the top and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com