Sludge freeze-thawing cycle conditioning and deep dewatering method

A technology of deep dehydration and freeze-thaw cycles, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problem of low sludge dehydration, many treatment devices, low dehydration performance, etc. problems, to achieve the effect of simple process operation, high degree of automation and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

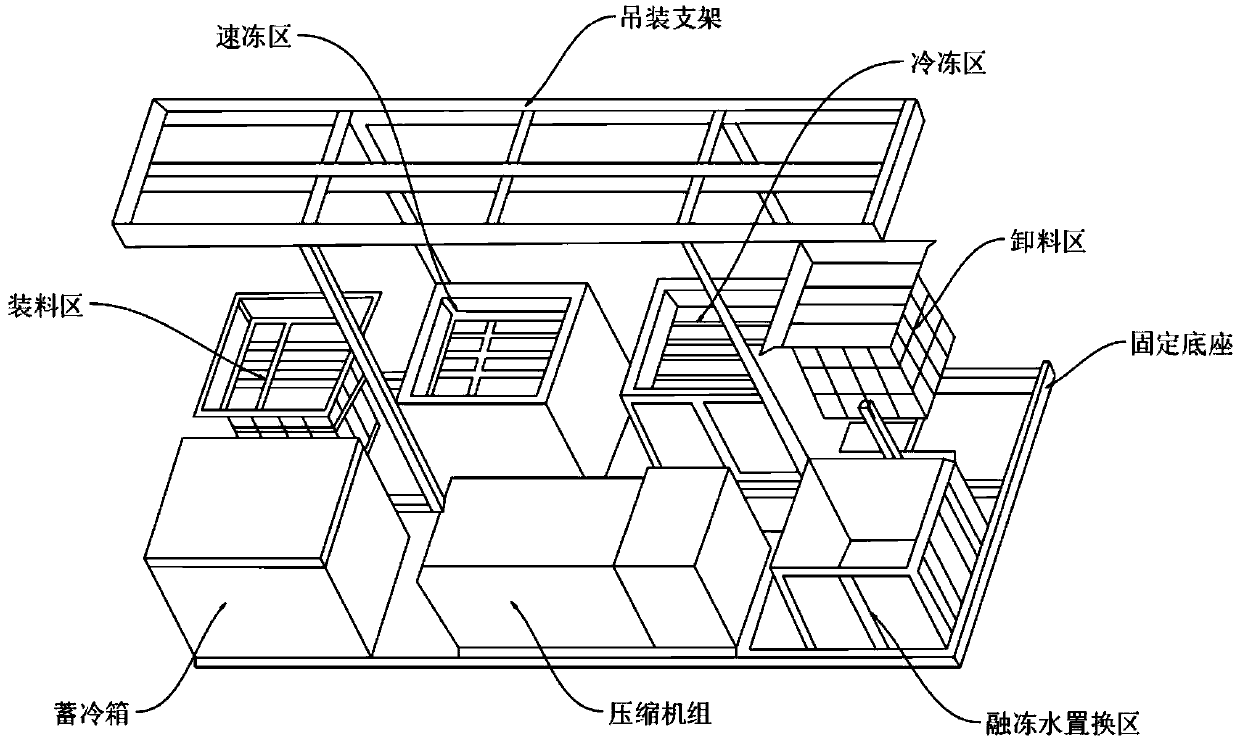

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

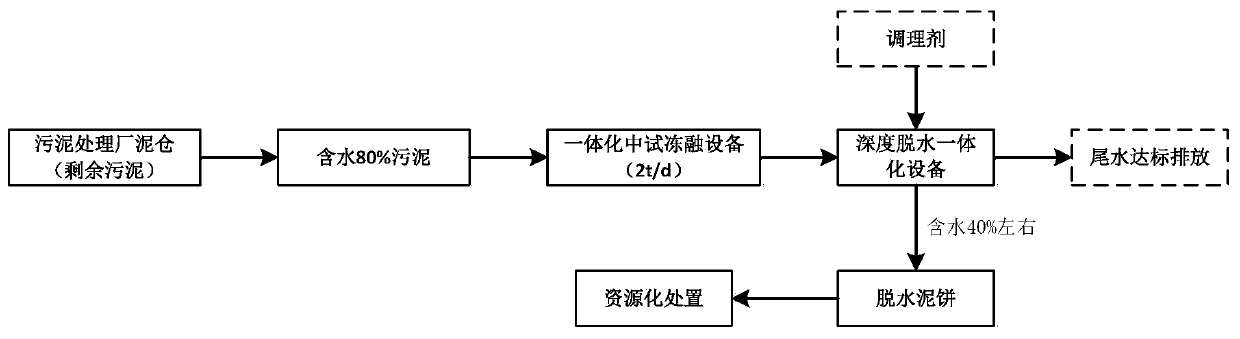

[0030] see Figure 1-2 , an embodiment provided by the present invention: a method for freezing and thawing and deep dehydration of sludge, comprising the following steps:

[0031] Step 1: Take the remaining sludge from the mud bin of the sewage treatment plant, and the moisture content of the sludge is 70% to 80%;

[0032] Step 2: Transport the sludge to the integrated freezing and thawing equipment for rapid freezing and thawing equipment. When the equipment is in the low-peak period of power consumption at night, the two units are started at the same time for 8 hours. Substance) for continuous cold storage, the coolant changes from a liquid phase to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com