Ultra-amphiphobic NFC (nano-fibrillated cellulose) aerogel based on directional freezing as well as preparation method and application of NFC aerogel

A nanocellulose, directional freezing technology, applied in the field of aerogel, can solve the problems of limited application range, high porosity and specific surface area, good hydrophilicity of nanocellulose aerogel, etc., to improve strength and application. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

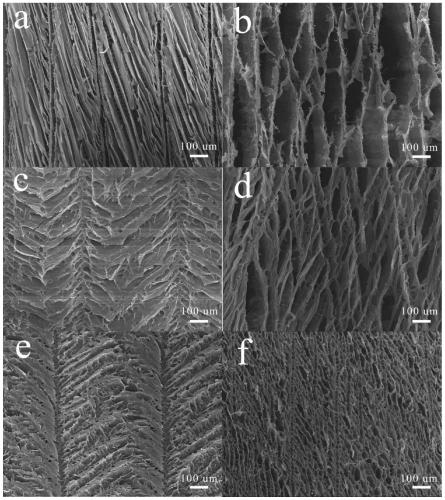

[0031] Below in conjunction with accompanying drawing of description, the present invention will be further described.

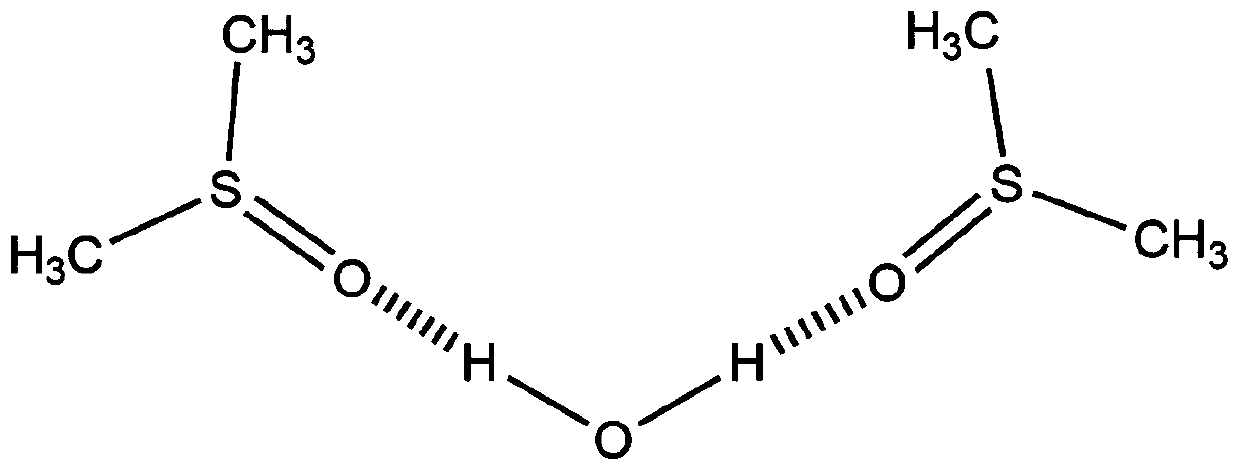

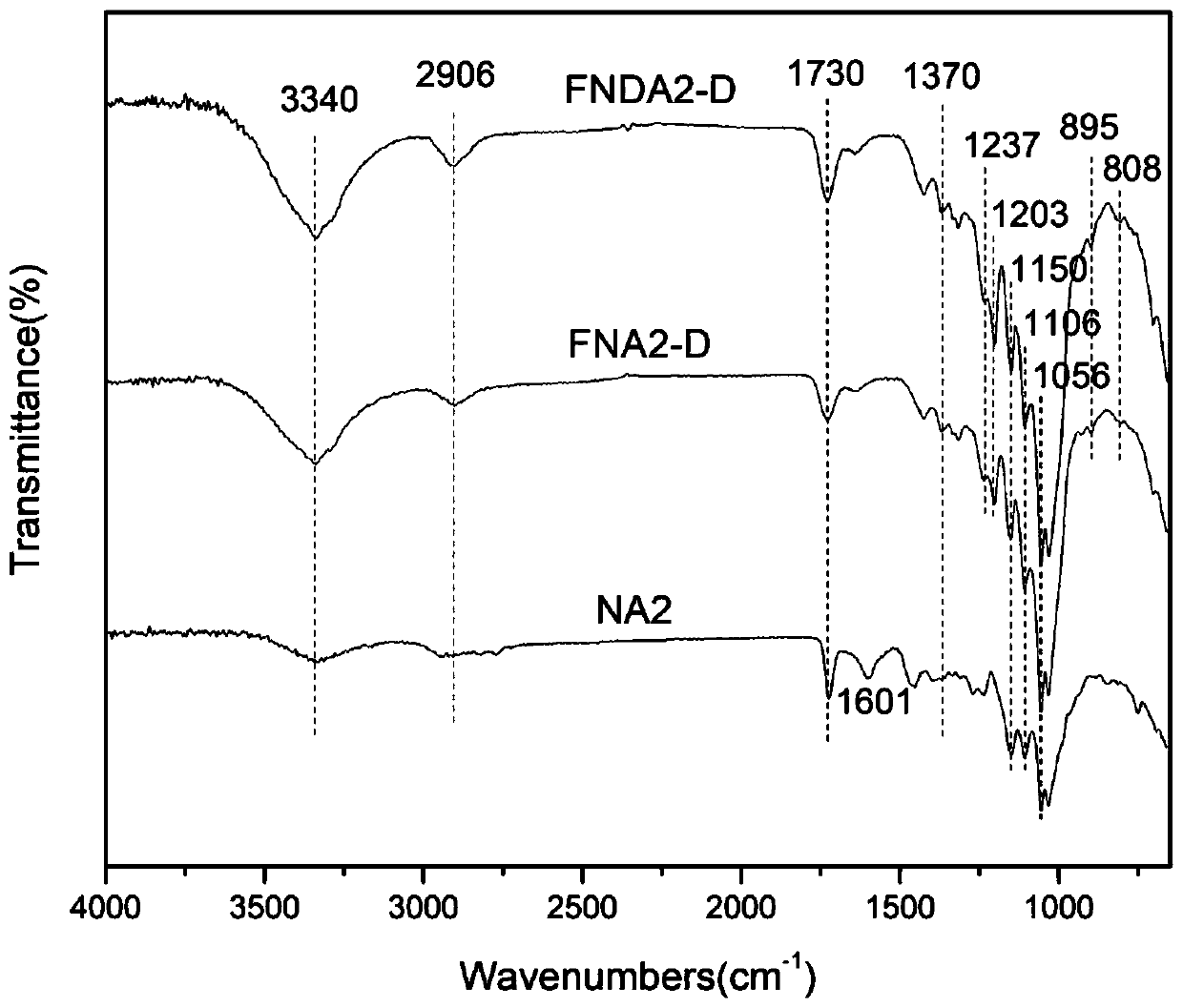

[0032] The invention provides a method for preparing super-amphiphobic nano-cellulose airgel based on directional freezing, using nano-cellulose (NFC) as a raw material and dimethyl sulfoxide (DMSO) as an additive, and preparing cellulose air based on directional freezing Gel; and then using trichloro-(1H,1H,2H,2H-heptadecafluorodecyl)silane as a low surface energy modification agent, the super amphiphobic nano-cellulose airgel was prepared by chemical vapor deposition modification .

[0033] Concrete preparation method comprises the following steps:

[0034] 1) Prepare nanocellulose with a set concentration by TEMPO oxidation;

[0035] 2) adding dimethyl sulfoxide to the nanocellulose solution, stirring evenly to prepare a mixed solution;

[0036] 3) Inject the mixed liquid into the mold, then wrap the two sides of the mold filled with the mixed liquid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com