A kind of production method of briquette

A production method and briquette technology, which is applied in the field of fly ash recycling, can solve the problem of low calorific value of briquette, and achieve the effects of avoiding pollution, saving manpower, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

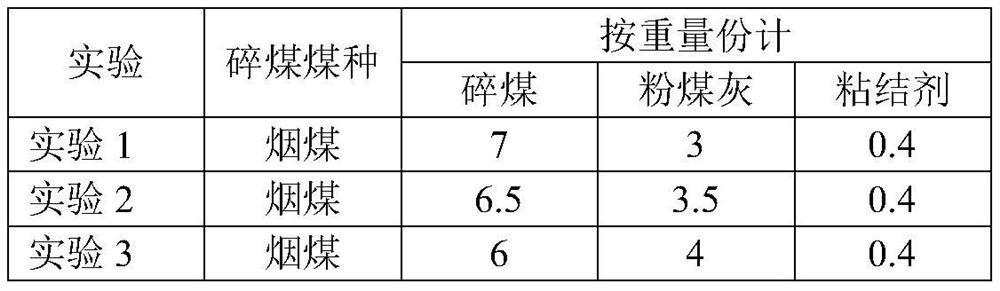

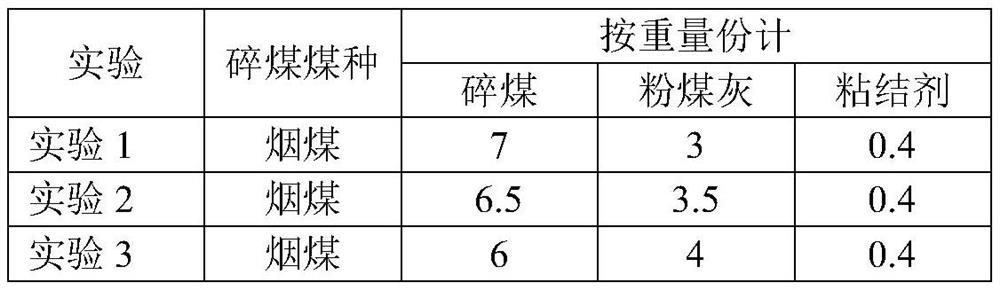

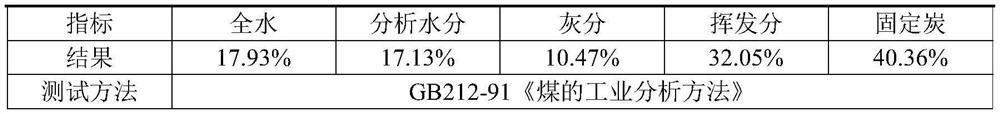

[0028] A method for producing coal briquettes, comprising the steps of:

[0029] Step 1: Concentrate the crushed coal, binder and fly ash, wherein the particle size of the crushed coal is ≤3mm, and the crushed coal is sieved coal for gasification.

[0030] Step 2: Stir and mix the material obtained in Step 1, and add water to the mixed material during the stirring process;

[0031] Step 3: pressing and molding the material obtained in Step 2 to obtain a semi-finished product; Step 4: drying the semi-finished product to obtain a finished coal briquette.

[0032] In the prior art, the particle size of pulverized coal is generally controlled within 0.6 mm. Under this premise, the amount of binder needs to be greatly increased, which makes it difficult to increase the calorific value of the coal briquette, which is not conducive to the promotion of the use of briquette coal. In this embodiment, crushed coal with a particle size of ≤3mm is mixed with fly ash, which is beneficial t...

Embodiment 2

[0036] A method for producing coal briquettes, comprising the steps of:

[0037] Step 1: Concentrate the crushed coal, binder and fly ash, wherein the particle size of the crushed coal is ≤3mm, and the crushed coal is the crushed coal sieved by gasification coal; the fly ash refers to the fluidized bed gasifier produced fly ash. Specifically, the fly ash is stored in the buffer bin, and the fly ash is quantitatively input into the first-stage twin-shaft mixer through the star-shaped ash discharge valve of the buffer bin, and the first-stage twin-shaft mixer is easy to obtain in the market , For example, the model produced by Zhengzhou Great Wall Metallurgical Equipment Co., Ltd. is the mixer of WJH2300. The pulverized coal with particle size ≤ 3mm screened by the sieving machine is transported to the first belt conveyor through the first quantitative feeder. The binder is conveyed to the first belt conveyor through the second quantitative feeder, and the pulverized coal toge...

Embodiment 3

[0046] A method for producing coal briquettes, comprising the steps of:

[0047] Step 1: Concentrate crushed coal, binder and fly ash. Specifically, the fly ash is stored in the buffer bin, and the fly ash is quantitatively input into the first-stage twin-shaft mixer through the star-shaped ash discharge valve of the buffer bin, and the first-stage twin-shaft mixer is easy to obtain in the market , For example, the model produced by Zhengzhou Great Wall Metallurgical Equipment Co., Ltd. is the mixer of WJH2300. The pulverized coal with particle size ≤ 3mm screened by the sieving machine is transported to the first belt conveyor through the first quantitative feeder. The binder is conveyed to the first belt conveyor through the second quantitative feeder, and the pulverized coal together with the binder is input into the first twin-shaft mixer through the first belt conveyor.

[0048] In step one, the particle size of the crushed coal is less than or equal to 3mm, and the cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com