Heat conduction vacuum gauge based on a fluorescence method

A vacuum gauge and heat conduction technology, which is applied in vacuum gauges, measuring devices, instruments, etc., can solve the problems of hot wire aging, lack of heat conduction vacuum gauge, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better clearly express the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

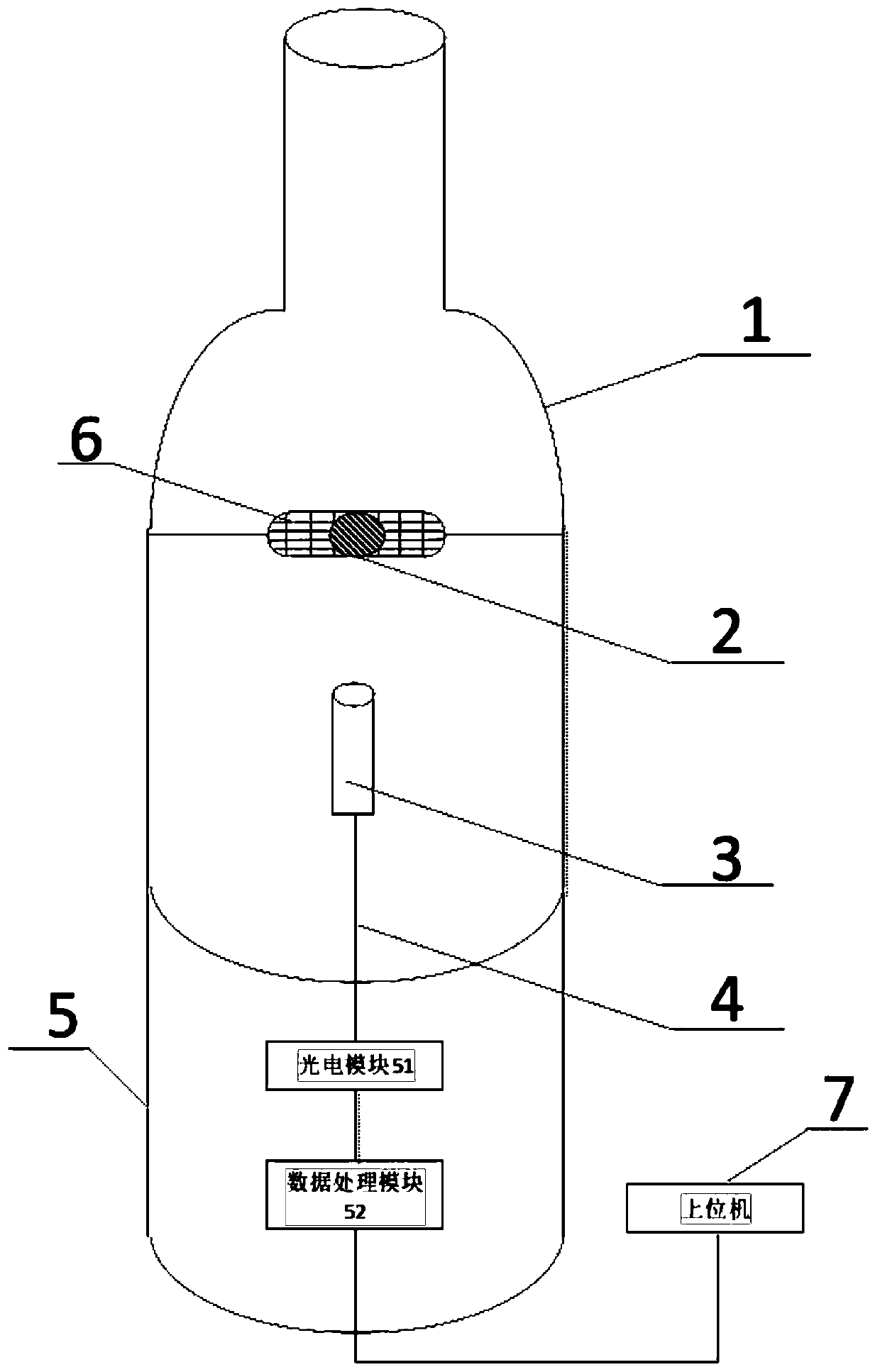

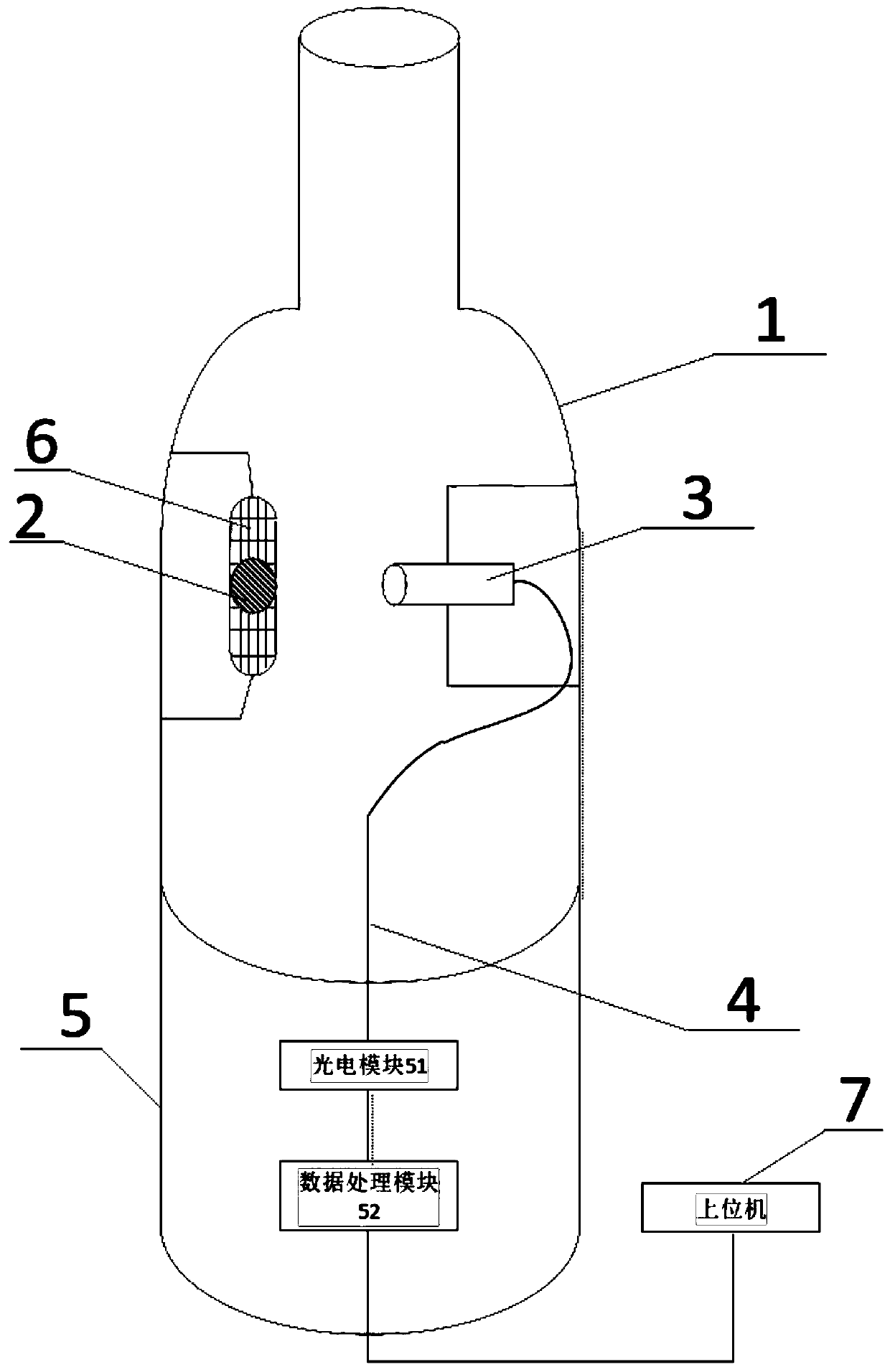

[0019] figure 1 According to a specific embodiment of the present invention, a schematic structural view of a heat conduction vacuum gauge based on the fluorescence method is shown, and as a preferred embodiment of the present invention, figure 2 It shows a structural schematic diagram of another heat conduction vacuum gauge based on the fluorescence method, and the present invention will combine figure 1 as well as figure 2 To further describe the specific embodiments of the present invention.

[0020] The purpose of the present invention is to provide a heat conduction vacuum gauge based on the fluorescence method, which is used to measure the air pressure and vacuum degree in the vacuum chamber. Just can obtain the temperature at the position of fluorescent material, then obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com