Mold for preparing ablation rate specimen and use method thereof

A technology of ablation rate and test pieces, which is applied in the field of molds for preparing ablation rate test pieces, can solve the problems of uneven size of test pieces, poor data stability, and potential safety hazards, so as to improve safety and accuracy and quality, the preparation method is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

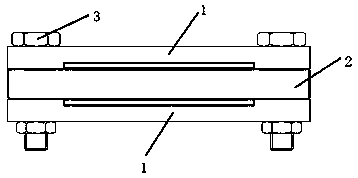

[0031] refer to Figure 1~3 , in an embodiment of the present invention, a mold for preparing ablation rate test specimens, the mold includes male molds 1 on both sides, two male molds 1 are arranged in parallel, and a piece of mold is arranged between the two male molds 1 The female mold 2 and the two ends of the male mold 1 are connected by bolts 3, and a four-sided closed frame is formed by the two male molds 1 and one female mold 2.

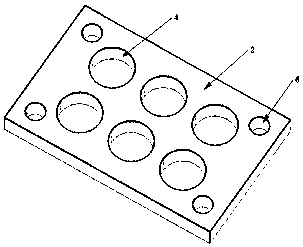

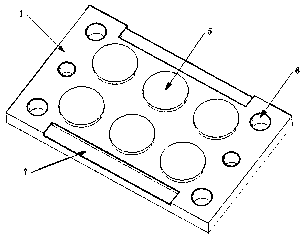

[0032] The middle part of the female mold 2 is provided with several test piece holes 4, the middle part of the male mold 1 is provided with several protrusions 5, and the four corners of the male mold 1 and the female mold 2 are provided with bolts that cooperate with the bolts 3. Hole 6.

Embodiment 2

[0034] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment lies in that the two side edges of the male mold 1 are provided with relief grooves 7 .

[0035] A method for using a mold for preparing an ablation rate test piece, comprising the steps of:

[0036] 1) Cut the test piece to be made into a shape with a size of φ30mm×10mm, put it into the female mold 2, and there are 6 sets of test pieces in total;

[0037] 2) Place the male mold 1 on the female mold 2 to ensure that the male and female molds can be well matched;

[0038] 3) Assemble and tighten with bolt 3;

[0039] 4) Put the assembled mold into the vulcanization box for vulcanization;

[0040] 5) After the vulcanization is over, take out the test piece and observe the outer surface of the test piece. The bonding between the test pieces is firm and there is no obvious delamination.

[0041] In the present invention, the steps of preparing the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com