Graphite felt-based bimetallic electrode and preparation method and application thereof

A technology of graphite felt and bimetal, which is applied in the field of graphite felt-based bimetal electrode and its preparation, can solve limited problems and achieve the effect of good application prospect, simple and reasonable preparation method and application method, and efficient reduction and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] One embodiment of the present invention proposes a preparation method of a graphite felt-based bimetallic electrode material, comprising the following steps:

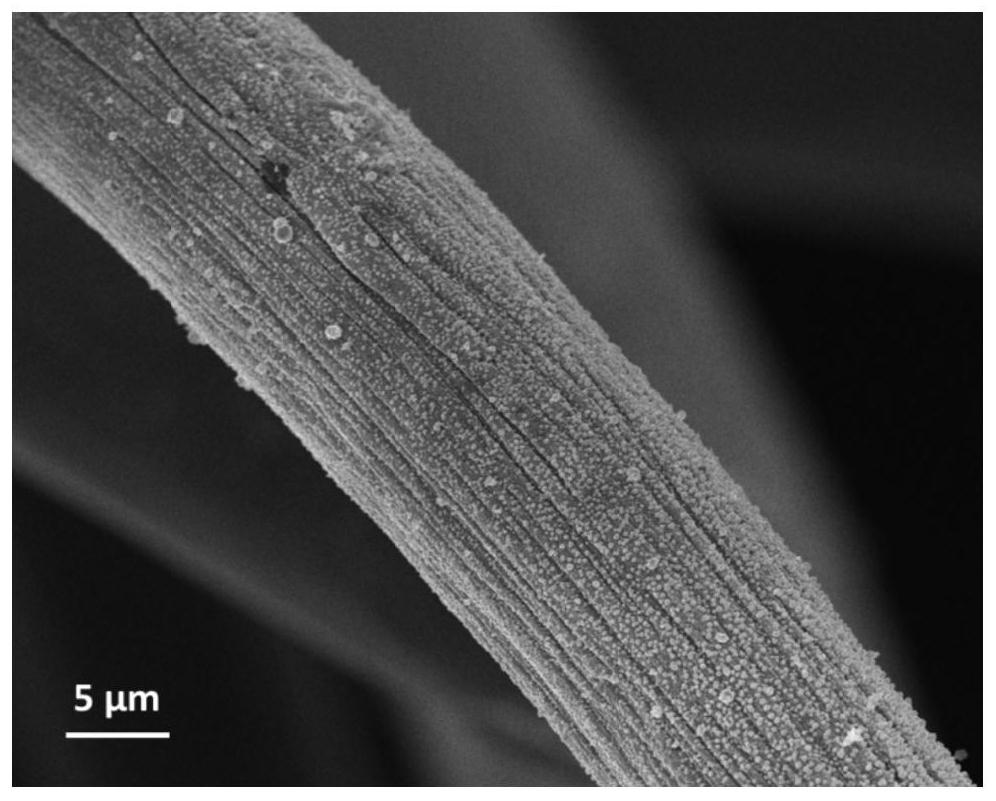

[0029] 1) Cut graphite felt into pieces, add nitric acid solution, after hydrothermal reaction, cool to room temperature, wash graphite felt until the surface is neutral, and dry;

[0030] 2) to NH 4 Add palladium chloride (PdCl 2 ) and indium trichloride (InCl 3 ), to obtain a mixed solution;

[0031] 3) with step 2) gained mixed solution is electrolytic solution, silver chloride (Ag / AgCl) is as reference electrode, and platinum (Pt) is as counter electrode, and step 1) gained graphite felt is as working electrode, connects electrochemical workstation, in Electrodeposition under constant current mode;

[0032] 4) The graphite felt after electrodeposition in step 3) is taken out, washed, and dried to obtain PdIn, a graphite felt-based bimetallic electrode material.

[0033] In an embodiment of the present in...

Embodiment 1

[0045] Example 1 A preparation method of graphite felt-based bimetallic electrode material, comprising the steps of:

[0046] (1) Cut the graphite felt (GF) into small pieces of 1.5cm*4cm, add 20mL of nitric acid, put it into a high-pressure reactor, and heat it in water at 120°C for 2 hours;

[0047] (2) Take out the graphite felt cooled to room temperature, wash with deionized water multiple times to make the surface pH wash to neutral, and then put it into an oven for drying at 40°C;

[0048] (3) Configure 50mL NH 4 Cl solution (10mM), which contains 3mMPdCl 2 and 3mM InCl 3 , immersing the above-mentioned graphite felt in the solution as a working electrode;

[0049] (4) Use Ag / AgCl as a reference electrode, Pt wire as a counter electrode, and graphite felt as a working electrode, connect to an electrochemical workstation, and electrodeposit for 30 minutes in constant current mode;

[0050](5) The electrodeposited graphite felt was taken out, washed with deionized wa...

Embodiment 2

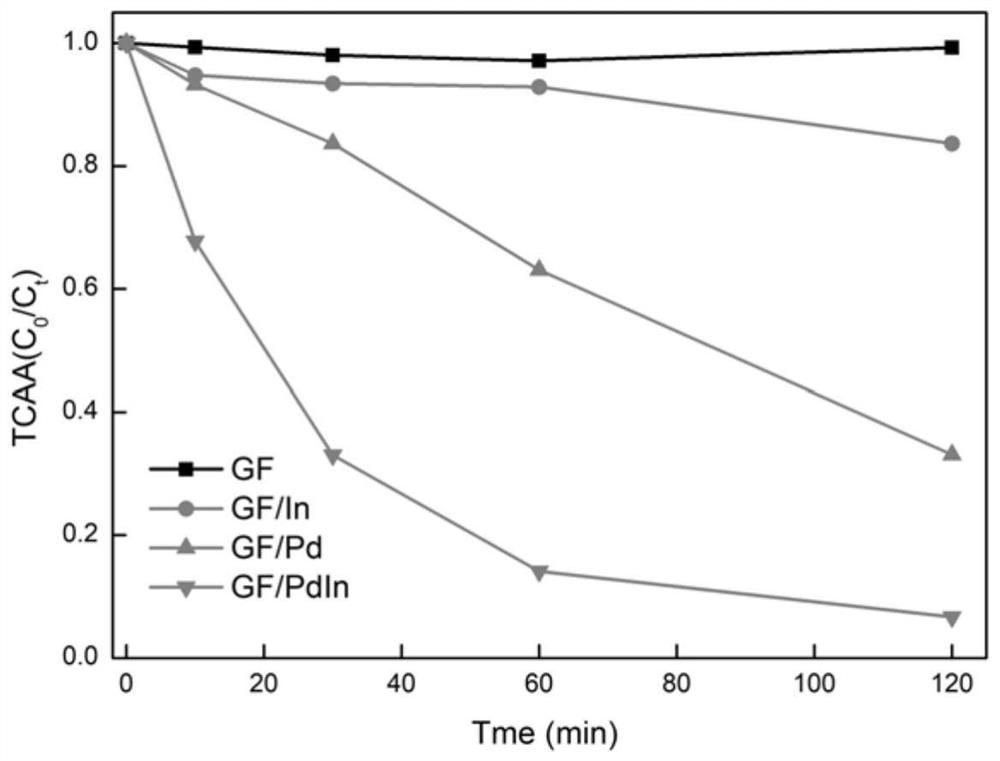

[0052] Example 2 Experiment of using graphite felt-based bimetallic electrode material to remove pollutants in water and increase energy production

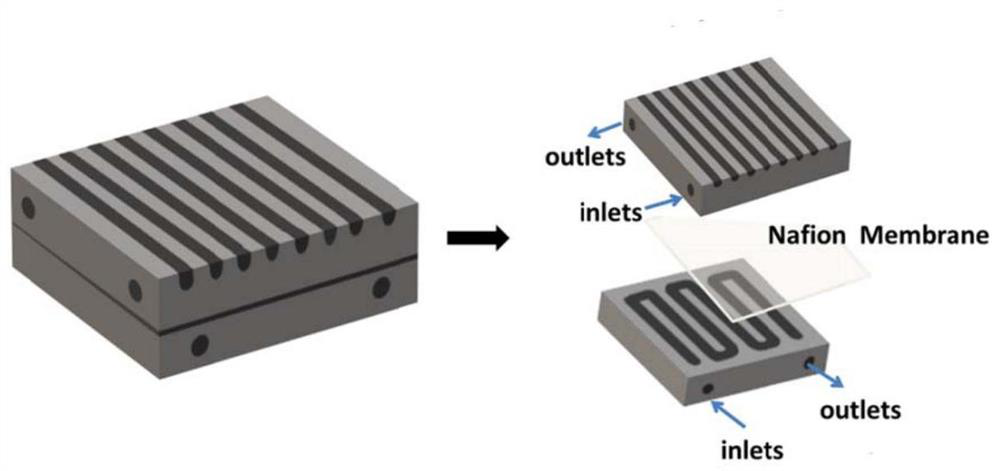

[0053] The bimetallic electrode material obtained in Example 1 is cut into slender strips, filled in the graphite pole plate gallery of the penetrating electrode reactor, as figure 2 As shown, it is mainly composed of graphite plates of two serpentine corridors and a Nafion117 diaphragm in the middle. During the loading process, the directions of the serpentine corridors are guaranteed to be perpendicular to each other. During the experiment, the water flow was pumped in from the hole on one side of the plate, flowed out from the hole at the end of the corridor, and returned to the beaker, so as to achieve the removal of pollutants. Take the pollutants trichloroacetic acid and bromate as examples to carry out specific experiments.

[0054] (1) Prepare 50 mL of 500 μg / L aqueous solution containing pollutant trichloroacetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com