Industrial robot training system combining vitality and reality and training method

An industrial robot, the technology of combining virtual and real, applied in the direction of instruments, simulators, simulation devices of space navigation conditions, etc., can solve the problems that industrial robots cannot be used alone, the training period is long, and the training efficiency is low, and it is conducive to rapid training of robots. The effect of operation and maintenance personnel, shortening training period and improving training efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

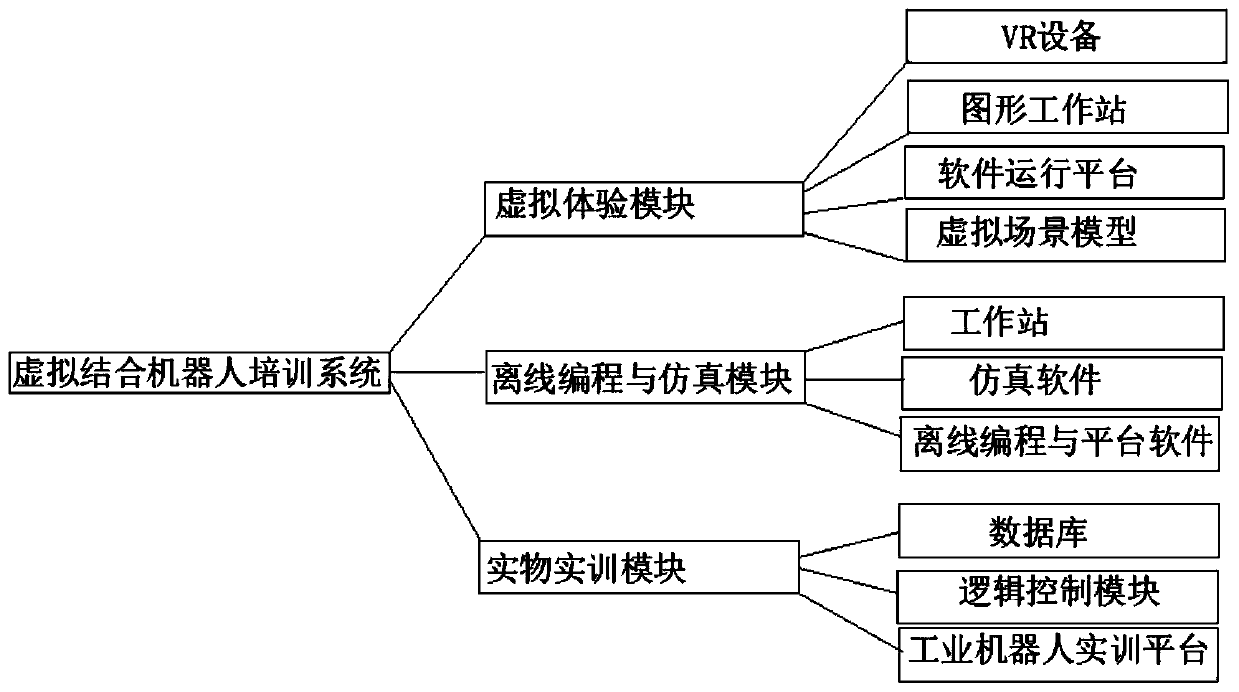

[0037] Embodiment 1: A kind of industrial robot training system combining virtual reality, such as figure 1 As shown, it includes a virtual experience module, an off-line programming and simulation module, and a physical training module; the virtual experience module includes a VR device, a graphics workstation for determining the operating position, a software operating platform, and runs on the software operating platform; offline programming The simulation module includes workstations for calculating and storing data, platform software for receiving data, simulation software for checking data results, and off-line programming software for generating correct execution commands; Execution command database, logic control module and industrial robot training platform;

[0038] like figure 1 As shown, the virtual experience module collects operation data and transmits it to the offline programming and simulation module. The offline programming and simulation module checks the d...

Embodiment 2

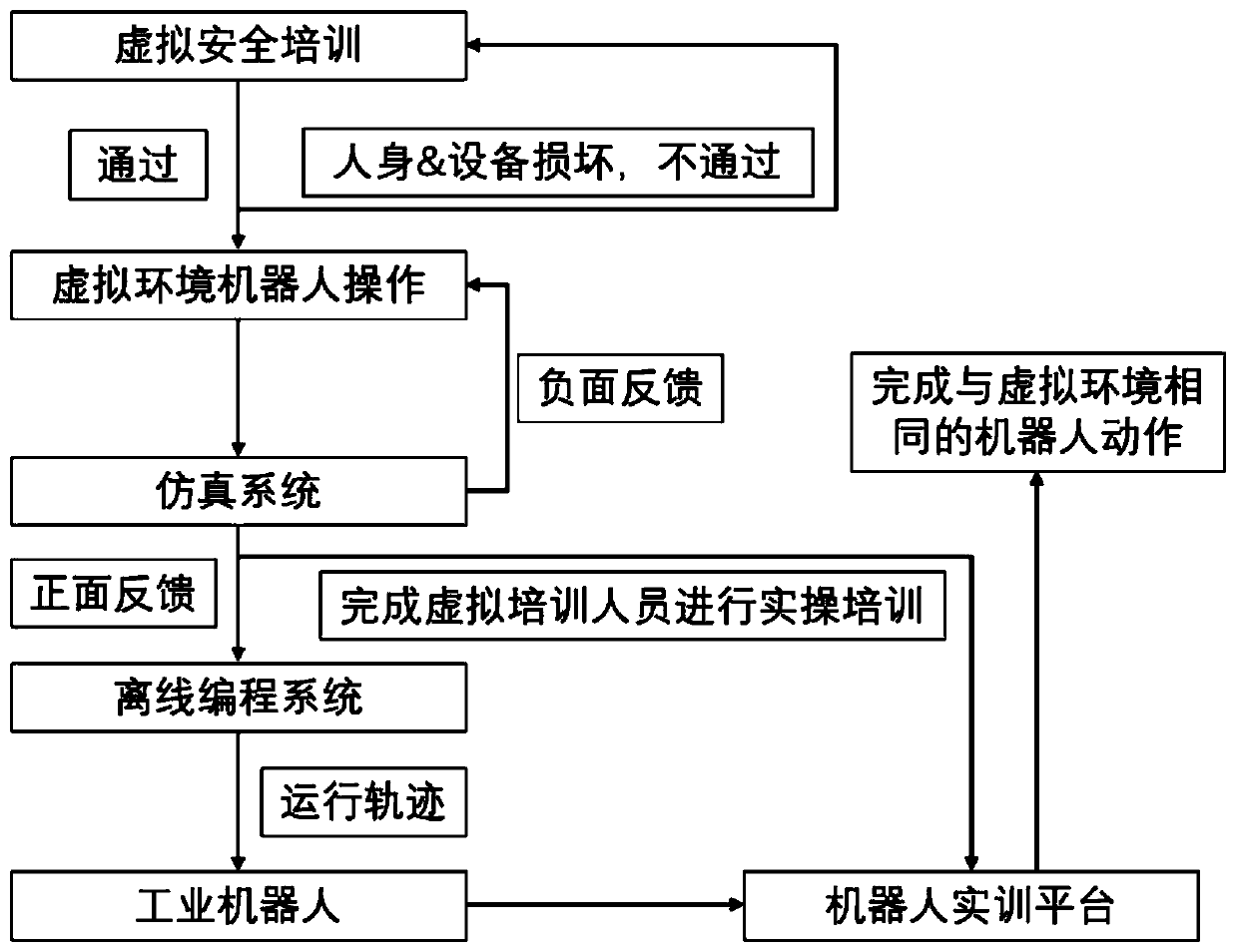

[0049] Embodiment 2: A training method for an industrial robot training system combining virtual reality, which is applied to an industrial robot training system combining virtual reality described in any one of the above, such as figure 2 shown, including the following steps:

[0050] S1: Conduct safety training

[0051] S1.1 trainers enter the virtual experience module, and conduct safety training in different scenarios through VR equipment and virtual scene models;

[0052] S1.2 If the safety training is completed, go to S2; if the equipment is damaged or the person is injured, return to S1.1 until the safety training is completed;

[0053] S2: Conduct virtual environment training

[0054] S2.1: Carry out robot operation training in the virtual scene model and transfer the data to the offline programming and simulation module;

[0055] S2.2: If the judgment of the simulation software is a positive test, go to S2.3; if the judgment of the simulation software is a negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com