A method for efficient defluorination of tail gas in wet-process phosphoric acid production

A wet-process phosphoric acid and tail gas technology, applied in phosphoric acid, separation methods, phosphorus oxyacids, etc., can solve the problems of reducing the comprehensive utilization rate of fluorine, polluting the environment, and incapable of absorbing and treating fluorine-containing gases, and achieves scaling mitigation and good efficiency. Exhaust gas scrubbing effect and fouling improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

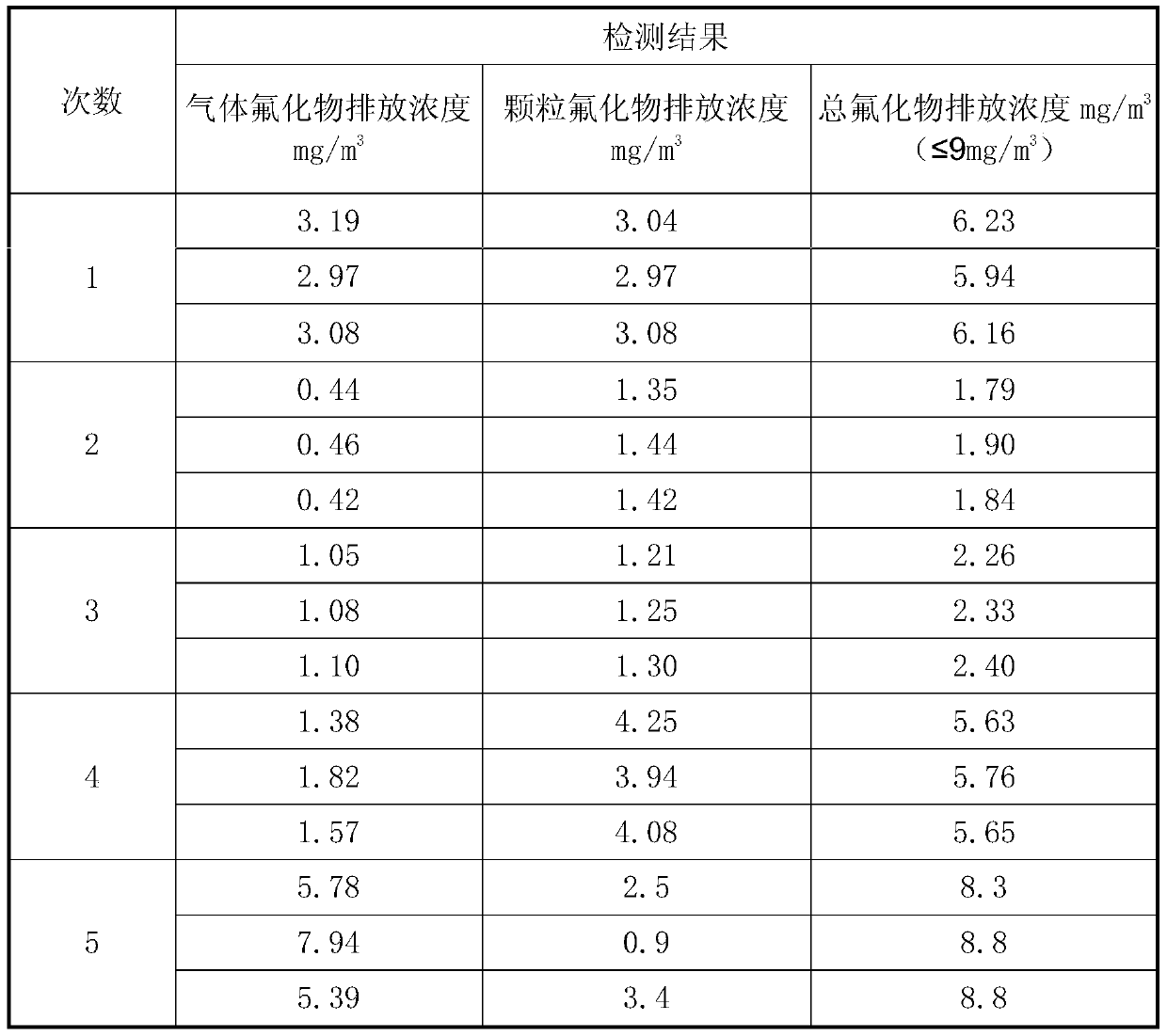

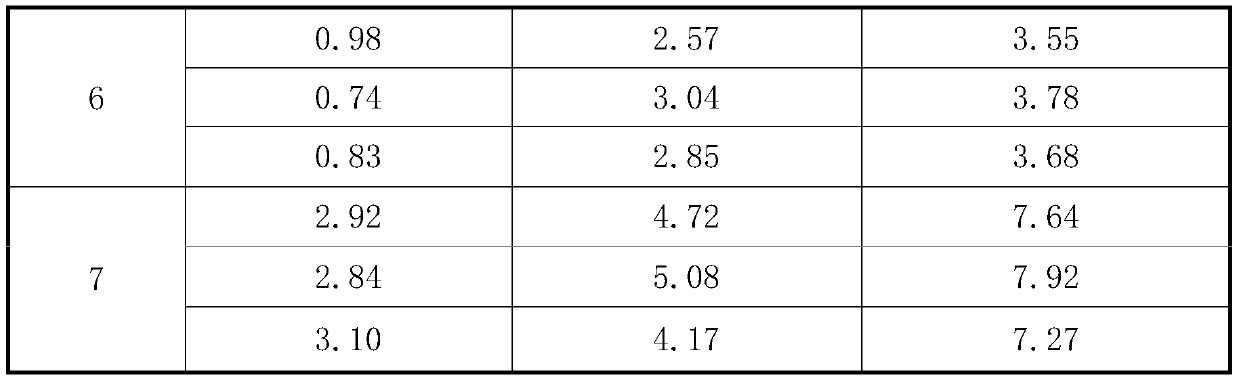

[0016] Phosphoric acid extraction tail gas defluorination project of Guizhou Kailin Group Mineral Fertilizer Co., Ltd.

[0017] Before the tail gas defluorination project of Guizhou Kailin Group Mineral Fertilizer Co., Ltd., the tail gas emission did not meet the standard (the gas fluoride emission concentration is about 11mg / m 3 , the emission concentration of particulate fluoride is about 4mg / m 3 , the average total fluoride content in exhaust gas exceeds 15mg / m 3 ), the exhaust system is seriously blocked, and the cleaning cycle is short (clearing once every 20 days).

[0018] The applicant aimed at a series of 250,000 tons of phosphoric acid units in Kailin Phosphoric Acid No. 2 Workshop, and adopted the following steps to transform them to reduce the fluoride content in the tail gas in the production of wet-process phosphoric acid: lengthen the sulfuric acid feeding pipe, and carry out anti-corrosion treatment (in The inner and outer surfaces of the 316L stainless steel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap