Spraying synergy electric car heat pump system

A technology for heat pump systems and electric vehicles, applied to vehicle parts, heating/cooling equipment, air handling equipment, etc., can solve problems such as increasing the compression ratio of the heat pump system, increasing the temperature of the exhaust gas, and insufficient heating capacity, so as to improve the cooling capacity. Thermal energy efficiency ratio, guaranteed heating efficiency, and the effect of increasing heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

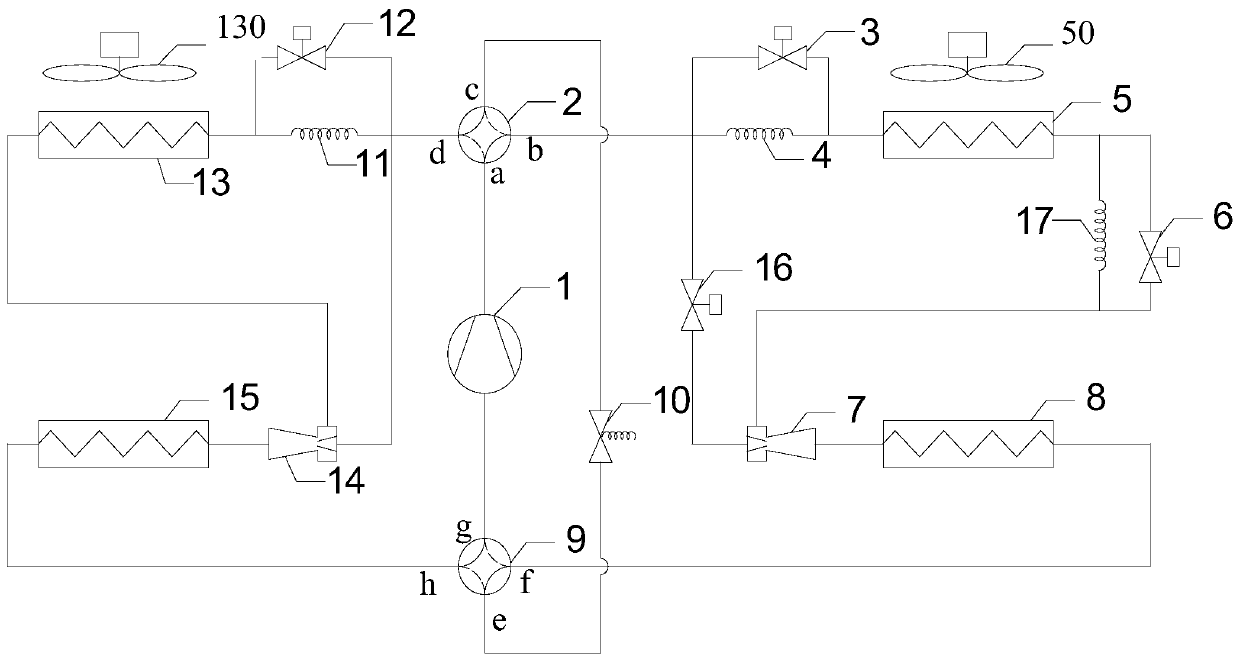

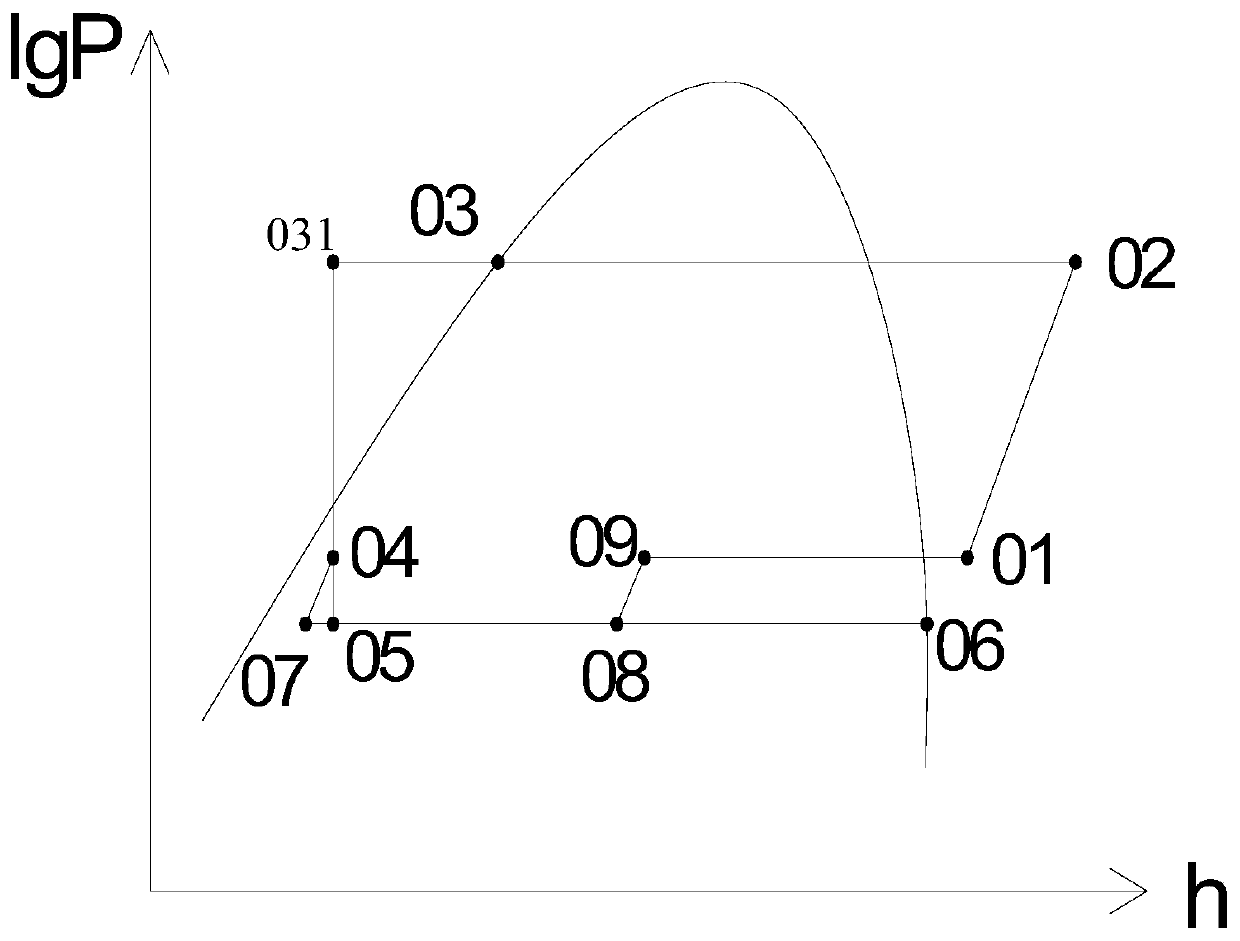

[0037] See figure 1 , figure 2 , The present invention provides a heat pump system for an injection-enhanced electric vehicle, including a compressor 1;

[0038] The refrigerant outlet (ie, exhaust port) of the compressor 1 is connected to the first port a of the first four-way valve 2;

[0039] The second port b of the first four-way valve 2 is respectively connected with one end of the first bypass valve 3, one end of the first capillary throttling device 4, and one end of the fourth bypass valve 16;

[0040] The third port c of the first four-way valve 2 is connected to one end of the expansion valve 10;

[0041] The fourth port d of the first four-way valve 2 is respectively connected to one end of the third bypass valve 12, one end of the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com