Ship sea chest grating copper-based antifouling composite coating

A composite coating and submarine door technology, which is applied in the field of marine ships, can solve the problems of high cost, rapid coating peeling, accelerated corrosion of the substrate, etc., and achieve good marine biological antifouling effect and reduce the effect of impact

Inactive Publication Date: 2019-09-03

725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The preparation process of this method is cumbersome, the cost is high, and the ceramic insulating intermediate coating must have extremely good insulation and anti-penetration properties, otherwise it will cause accelerated corrosion of the substrate and rapid peeling off of the coating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] The following examples are used to describe the implementation of the present invention in detail, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

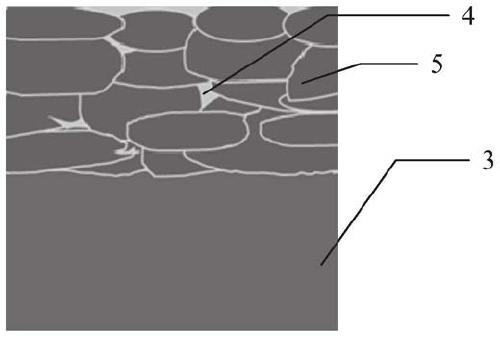

The invention provides a ship sea chest grating copper-based antifouling composite coating. The ship sea chest grating copper-based antifouling composite coating comprises a copper or copper alloy base coating and a self-polishing sealing material coating, wherein a self-polishing sealing material permeates into pores of the copper or copper alloy base coating. According to the ship sea chest grating copper-based antifouling composite coating, a self-consuming organic coating technology is adopted, and a self-polishing sealing material of zinc acrylate resin or acrylic silicone resin is used as a hole sealing agent of the copper-based coating so that it can be guaranteed that a corrosion medium cannot penetrate the coating, the anti-fouling function of the copper-based antifouling coatingcan be guaranteed to achieve stably, then the coating can achieve a good marine organism antifouling effect, and the influence of marine organism on the matrix material is reduced to the maximum extent.

Description

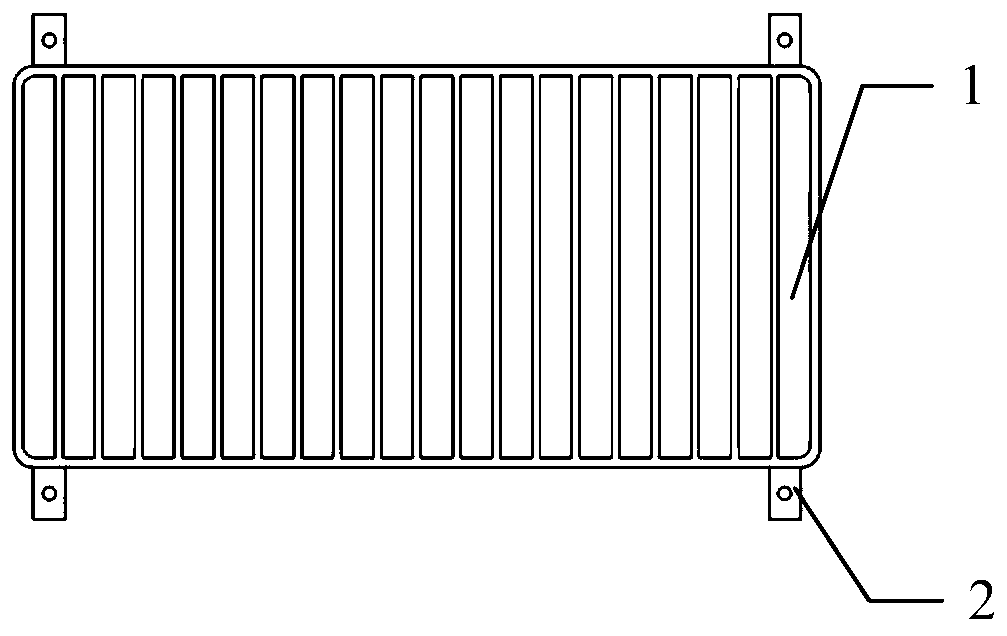

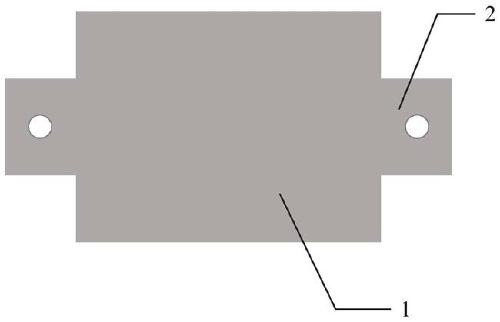

technical field [0001] The invention belongs to the technical field of marine ships, and relates to a copper-based antifouling composite coating for a ship's submarine door grid. Background technique [0002] Marine biofouling has always been one of the challenges faced by the marine industry. Submarine door grille is the part where marine biofouling occurs frequently: conventional antifouling coatings are difficult to ensure the adhesion on the grille surface under the scouring of high-speed water flow and the impact of solid impurities, and cannot play an effective antifouling effect. [0003] Cuprous ions can effectively inhibit the growth and aggregation of marine organisms, and cuprous oxide is added as an antifouling agent in many antifouling coatings. Copper or copper alloy itself corrodes in seawater, and it will also release cuprous ions, which inhibit the growth of marine organisms. Therefore, it is often used in marine structures that are sensitive to marine biof...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C4/12C23C4/18C23C24/04B05D5/00C23C4/06

CPCB05D5/00C23C4/06C23C4/12C23C4/18C23C24/04

Inventor 邢路阔李相波黄国胜刘亚鹏

Owner 725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com