Water spraying and flushing device for fabric

A technology for water spray washing and fabrics, which is applied in the fields of fabric water spray washing devices and printing and dyeing machinery, can solve the problems of large water consumption and low efficiency of knitted fabric water tank, and achieves the effect of saving water source and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure of the present invention is further described below:

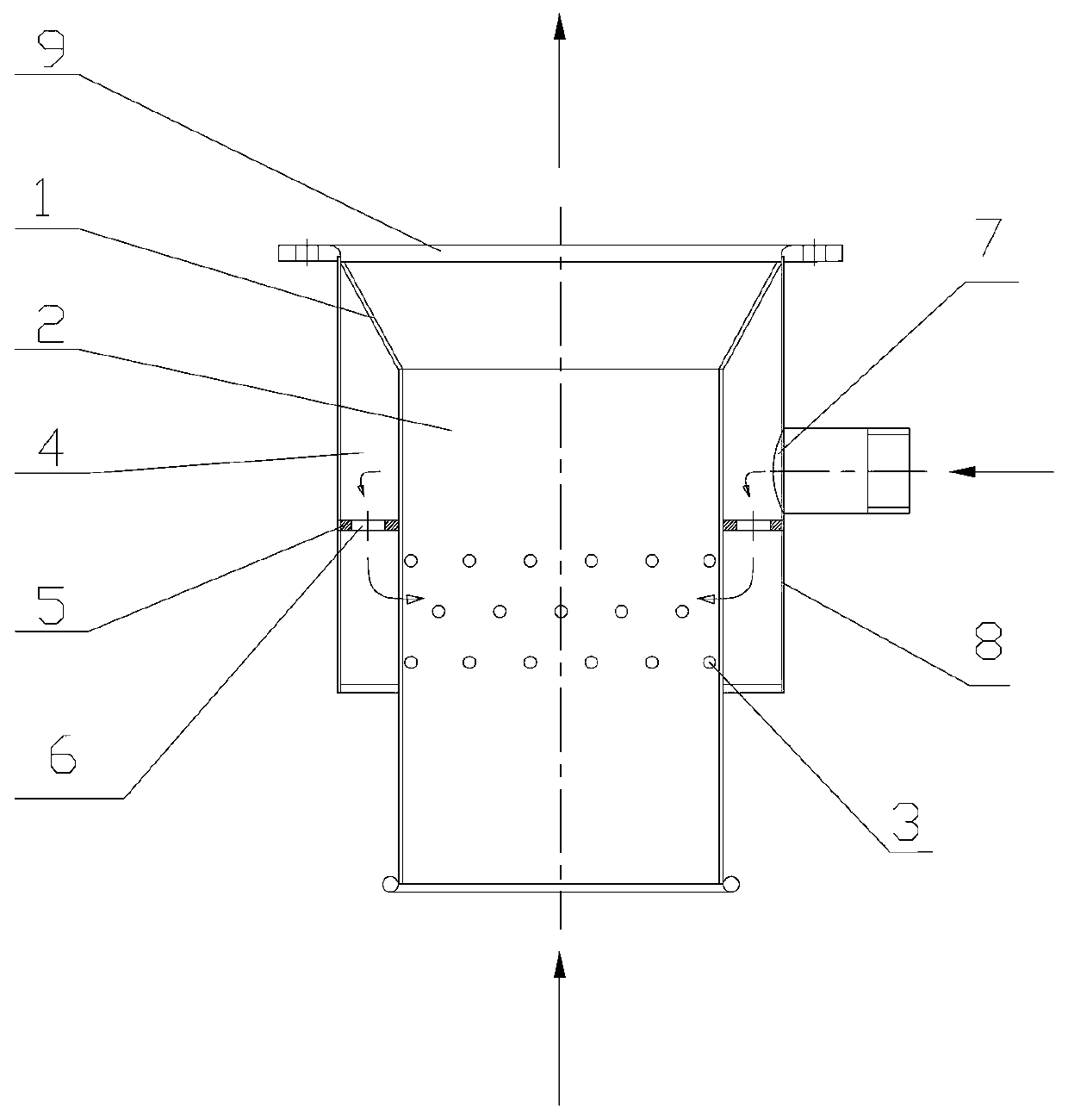

[0020] Fabric water spray washing device structure of the present invention is as figure 1 and figure 2 As shown, the water spray tube 2 is included, and the upper part of the water spray tube 2 is provided with a reaming discharge cylinder 1. The reaming hole of the reaming discharge cylinder 1 is upward.

[0021] The side wall of the water spray tube 2 is provided with spray holes 3, and the spray holes 3 are distributed on the side wall of the water spray tube in multi-layer equidistant. The nozzle holes 3 are evenly arranged around the side wall of the water spray cylinder 2. The outer surface of the water spray cylinder 2 is provided with a cylindrical outer cylinder body 8, the upper and lower ends of the outer cylinder body 8 are closed, and the space between the outer cylinder body 8 and the water spray cylinder 2 The standing water chamber 4 is formed. The standing water chamber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com