Electric fast transient-based industrial robot servo driver detection method

A technology of servo drive and industrial robot, which is applied in the direction of measuring electrical variables, electrical testing/monitoring, instruments, etc., can solve the problems of lack of research in the field of industrial robots and few electrical fast transient pulse groups, and achieve high innovation and engineering applications performance, improved reliability, and high reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

[0036] The detection method of the industrial robot servo drive based on the electric fast transient pulse group, the specific steps are as follows:

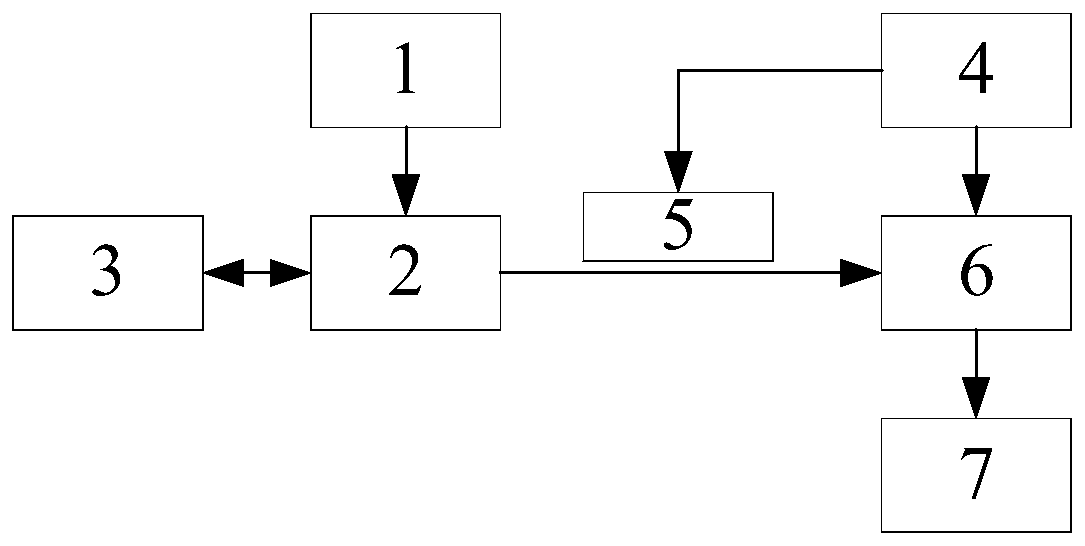

[0037] Step 1, such as figure 1 As shown, a detection system is built; the detection system includes a switching power supply 1 , a controller 2 , a host computer 3 , a capacitive coupling clip 4 and a coupling and decoupling network 5 . The model of controller 2 is PLC with model DVP-50MC-60T. The coupling and decoupling network 5 includes a coupling device and a decoupling device for filtering irrelevant signals and coupling the interference pulse signal to the power line of the equipment under test. The capacitive coupling clip 4 couples the interference pulse signal to the signal line of the equipment under test. The switching power supply 1 steps down the 220V power supply to a 24V power supply to supply power for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com