Pulp pH meter intermittent flushing device based on automatic control and use method of pulp pH meter intermittent flushing device

A flushing device and intermittent technology, applied in the field of the intermittent flushing device of the pulp pH meter, can solve the problems of easy fouling of the pH meter, untimely detection of the pH meter, and difficulty in cleaning, etc., so as to ensure the quality and recovery rate, and reduce the labor of workers. Strength, the effect of avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

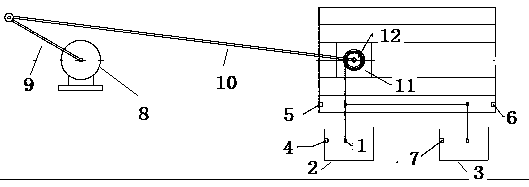

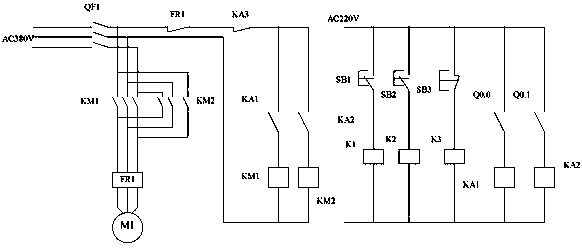

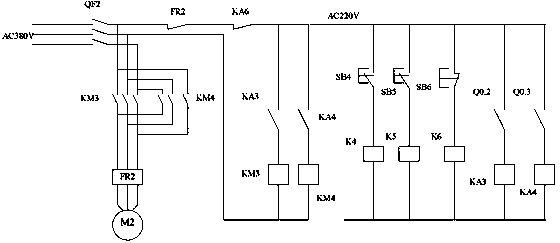

[0026] Embodiment 1: The driving mechanism includes a crank-slider mechanism, and the crank-slider mechanism includes a driving member 9 driven to rotate by a first motor (which may be called a motor 2 ) 8, and a connecting rod 10 rotationally connected to the driving member And the slider 11 connected with the connecting rod, the second motor 12 (which can be called motor 1) connected with the pH meter is installed on the slider, the first motor drives the slider to move horizontally, and the second The motor drives the pH meter to move up and down. The measuring point position switch can be called I(0.0), the first limit position switch can be called I(0.1), the second limit position switch can be called I(0.2), and the flushing point position switch can be called It is I (0.3), and the position switch of the flushing tank can be called I (0.8), which is not marked in the figure, and the above switches are proximity switches.

Embodiment 2

[0027] Embodiment 2: The difference from Embodiment 1 is that the measuring point position switch, the first limit position switch, the second limit position switch, the flushing point position switch and the flushing tank position switch are travel switches.

Embodiment 3

[0028] Embodiment 3: The use method of the intermittent flushing device of the pulp pH meter based on automatic control, which includes the following steps: (1), the pH meter measures the pH value of the pulp in the pulp mixing device; (2), after the measurement is completed, pass the second The motor moves the pH meter to the first limit position switch, the second motor stops, the first motor drives the slider to move horizontally so that the pH meter is moved to the second limit position switch, the first motor stops, and the second motor drives the pH meter Move down to the position switch of the flushing point, the second motor stops, the position switch of the flushing tank opens the flushing water solenoid valve to flush the pH meter, and the liquid after flushing enters the slurry mixing device for secondary use; (3), the pH meter after flushing presses The original path returns to the pulping device to continue measuring the pH value of the pulp, and so on.

[0029] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com