Lens trimming and fine grinding machine

A fine grinder and trimming technology, which is applied in the field of lenses, can solve the problems of affecting the grinding and cleaning effect, waste, etc., and achieve the effect of flexible design and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

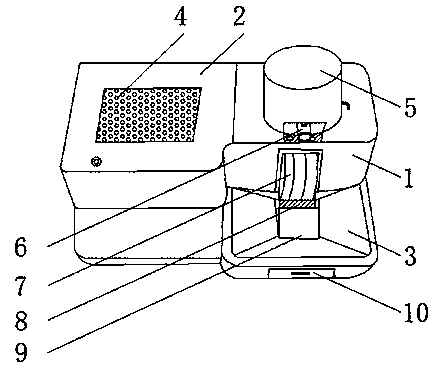

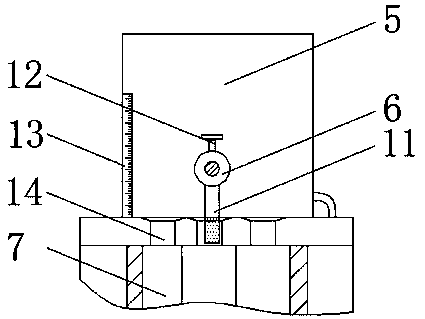

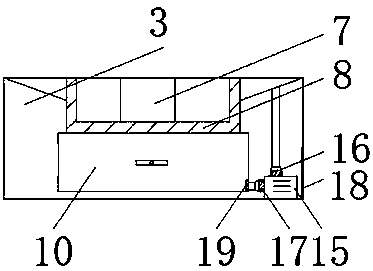

[0021] Such as Figure 1-3 As shown, a lens trimming and fine grinding machine includes a main body housing 1, a motor housing 2 located on one side of the main housing 1, and a base 3 located at the bottom of the main housing 1. A grinding wheel 7 is installed inside the main housing 1, so The inside of the motor housing 2 is equipped with a motor, and the output end of the motor is connected with the grinding wheel 7. The top of the motor housing 2 is provided with a heat dissipation port 4, and the top of the main body housing 1 is provided with a water storage tank 5. The water storage tank One side of 5 is equipped with a rotatable and adjustable water outlet valve 6, and the top and bottom ends of the water outlet valve 6 surface are respectively provided with a regulating water valve 12 and a silicone hose 11, and the transfer area between the grinding wheel 7 and the top surface of the base 3 is opened There is a water inlet tank 8, and the inner drawer of the base 3 i...

Embodiment 2

[0026] Such as figure 1 As shown, the surface of the base 3 is a quadrangular funnel shape, and the surface of the base 3 is welded with a water retaining block 9 at the side of the water inlet tank 8, which corresponds to the position of the grinding wheel 7. The base 3 and the water retaining block 9 are arranged Block 9, the water blocking block 9 prevents water from splashing randomly when the lens is polished from the horizontal direction, and the surface of the base 3 is a quadrangular funnel shape, which is convenient for collecting part of the splashed water, and the water droplets finally slide into the water inlet tank 8 due to gravity;

[0027] Such as image 3 As shown, the soft water pipe welded on one side of the bottom of the water collection box 10 extends to the part of the water collection box 10 equipped with a filter screen 19, and the filter screen 19 is a mosquito net cloth or a mesh diameter between 0.5-1mm. mesh between

[0028] Through the provided m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com