Double-row air valve film and preparation method thereof

A technology of exhaust valve and air valve film, applied in chemical instruments and methods, automatic packaging control, containers, etc., can solve problems such as limiting the production efficiency of air column bags, achieve good air lock effect, reduce production energy consumption, tailoring handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

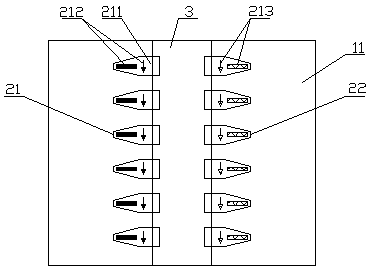

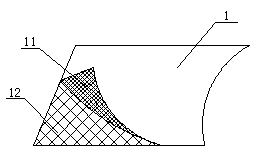

[0023] Such as Figure 1~2 As shown, a kind of double exhaust valve membrane of the present invention comprises valve membrane body 1, and described valve membrane body 1 comprises two layers of upper film 11 and lower film 12, wherein upper film 11 is a printing layer, lower film 12 It is a composite layer; two rows of heat-resistant ink layers 2 are arranged in parallel on the inner surface of the upper film 11, and the heat-resistant ink layers 2 are distributed at equal intervals along the longitudinal direction of the upper film 11; specifically, the The heat-resistant ink layer 2 is one of conical, duckbill-shaped, rectangular, circular, elliptical, polygonal or trapezoidal structures, and the conical shape with a small head and a large tail can be given priority, which is beneficial to achieve fast air intake during inflation and comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com