Waste pollution fermentation device

A fermentation device and carrying device technology, which is applied in the field of machinery, can solve the problems of small fermentation equipment, high operating power, and low processing capacity, and achieve the effects of shortening fermentation time, large processing capacity, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

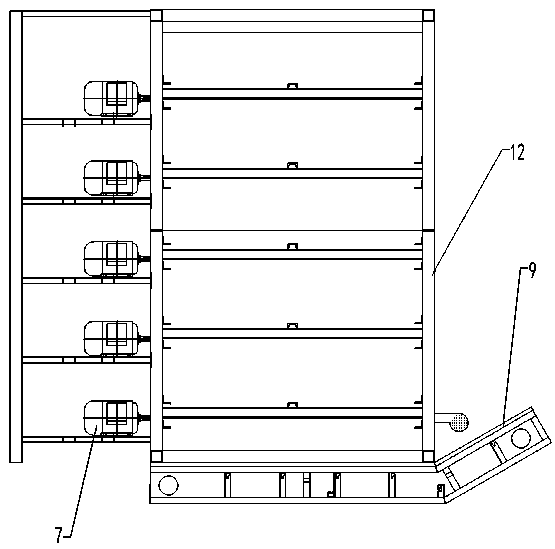

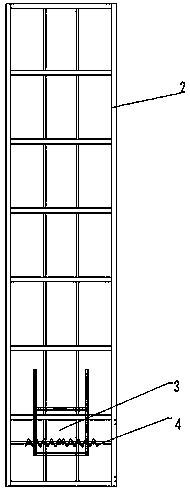

[0028] Examples such as Figure 1-5 As shown, a waste sewage fermentation device includes a box-shaped equipment main body 2. A carrying device capable of carrying materials in a large capacity is installed in the equipment main body 2. Throwing device, one side of the equipment main body 2 is connected with a heating device.

[0029] The carrying device includes a plurality of conveying units arranged in parallel up and down, and each conveying unit is a net chain 6 for carrying materials, and the net chain 6 is a net chain conveyor belt.

[0030] The two net chains 6 adjacent up and down are dislocated along the length direction of the equipment main body 2. This design is to facilitate the material on the net chain 6 above to fall on the net chain 6 below.

[0031] The drive motor 7 is connected to the transmission on the net chain 6, and the drive motor 7 rotates to drive the net chain 6 to rotate and make the material move in a specific direction. The drive motor 7 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com